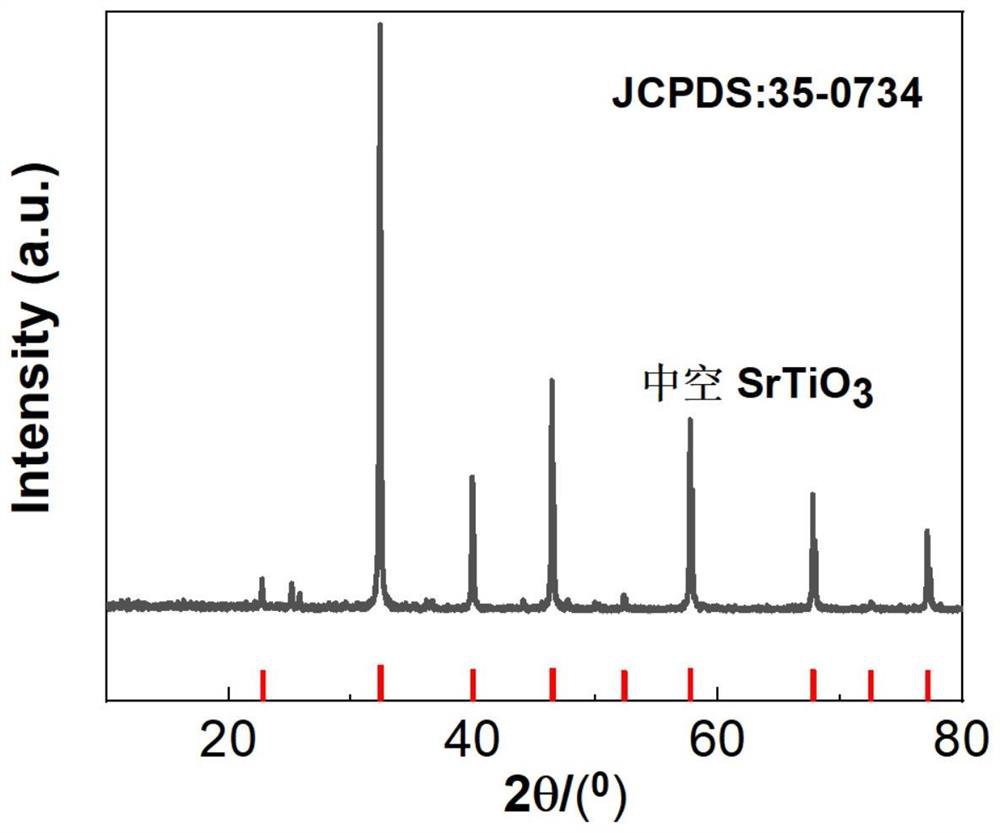

Method for preparing porous hollow monocrystal strontium titanate

A strontium titanate, single crystal technology, applied in titanate, chemical instruments and methods, alkaline earth metal titanate, etc., can solve the problems of unfavorable photogenerated charge transport, photocatalytic water splitting reaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

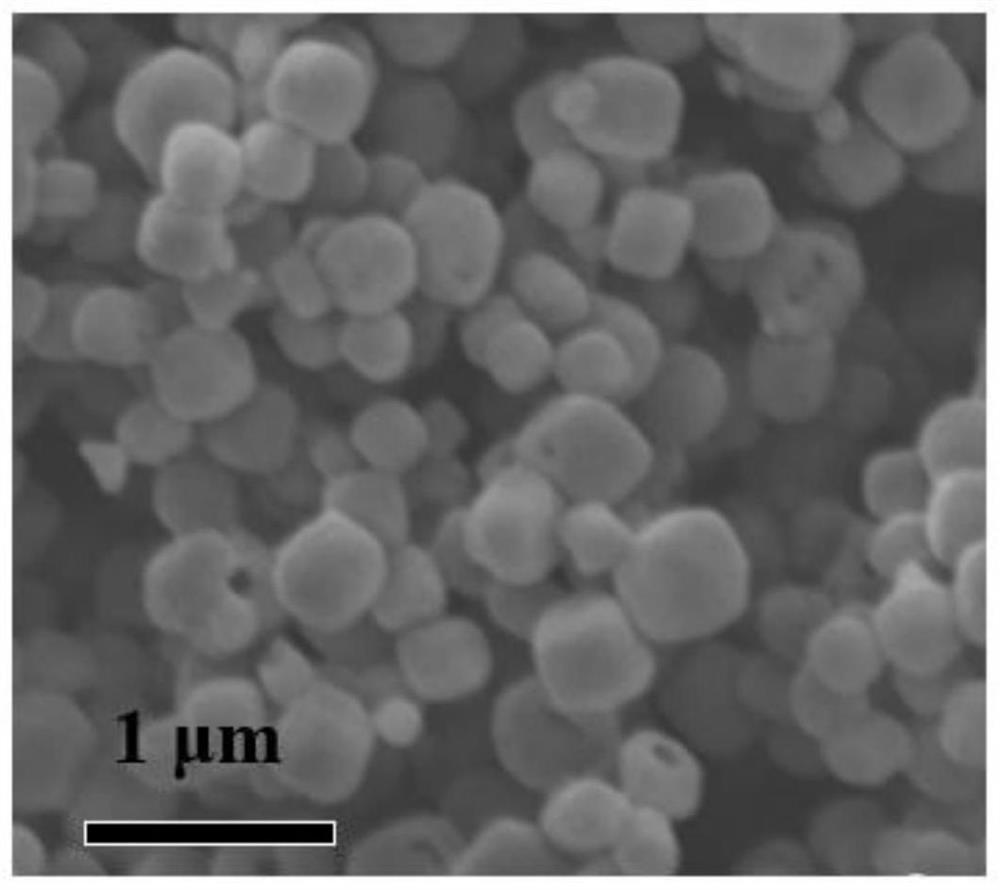

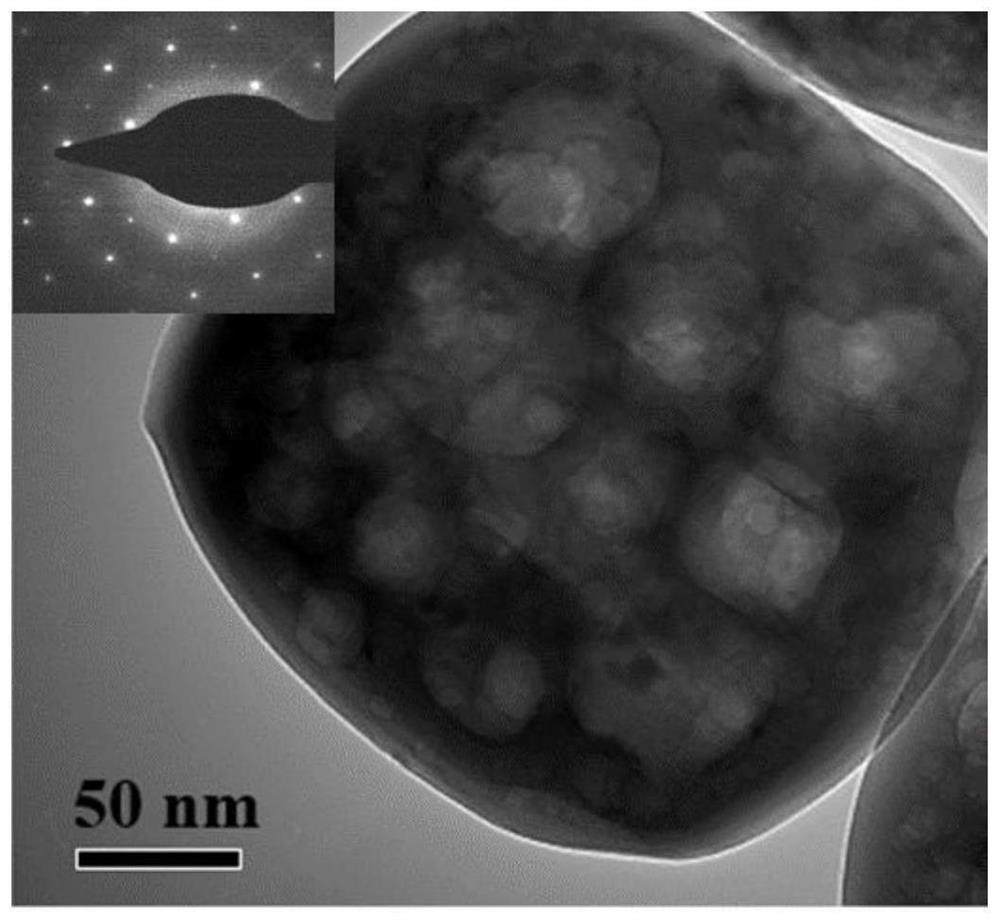

[0025] In this example, porous hollow single-crystal strontium titanate was prepared by using methanol as a shape control agent.

[0026] The preparation process of the carbon sphere template: first prepare a glucose solution with a concentration of 0.5mol / L, take 44ml and put it into a 50ml polytetrafluoroethylene reactor, the water heating time is 6h, and the temperature is 180°C.

[0027] Preparation of porous hollow single crystal strontium titanate: 0.26ml of TiCl 4 Add dropwise into 25ml of deionized water containing 2g of methanol, mix well, add 90mg of carbon spheres, and ultrasonically mix it, then add 4g of LiOH·H 2 O in 30ml deionized water, after stirring for 30min, add 10ml containing 0.7g SrCl 2 ·6H 2 O solution, after stirring for 30 minutes, the solution was transferred to a 100ml polytetrafluoroethylene reactor, the hydrothermal reaction temperature was 180°C, and the reaction time was 24h. The sample was collected by centrifugation with deionized water to o...

Embodiment 2

[0029] On the basis of Example 1, porous hollow single-crystal strontium titanate with different shapes was obtained by adjusting the amount of carbon sphere template.

[0030] The preparation process of the carbon sphere template: first prepare a glucose solution with a concentration of 0.5mol / L, take 44ml and put it into a 50ml polytetrafluoroethylene reactor, the water heating time is 6h, and the temperature is 180°C.

[0031] Preparation of porous hollow single crystal strontium titanate: 0.26ml of TiCl 4 Add dropwise to 25 ml of deionized water containing 2 g of methanol. After mixing evenly, add 200 mg of carbon spheres, mix it ultrasonically, and add 4 g of LiOH·H 2 O in 30ml deionized water, after stirring for 30min, add 10ml containing 0.7g SrCl 2 ·6H 2 O solution, after stirring for 30 minutes, the solution was transferred to a 100ml polytetrafluoroethylene reactor, the hydrothermal reaction temperature was 180°C, and the reaction time was 24h. The sample was coll...

Embodiment 3

[0033] In this example, the porous hollow strontium titanate prepared by taking 1,2-propanediol as an example, the preparation process is similar to that of Example 1 and Example 2.

[0034] The preparation process of the carbon sphere template: first prepare a glucose solution with a concentration of 0.5mol / L, take 44ml and put it into a 50ml polytetrafluoroethylene reaction kettle, the water heating time is 6h, and the temperature is 180°C.

[0035] Preparation of porous hollow samples: 0.26ml TiCl 4 Add dropwise to 1 g of 1,2-propanediol in 25 ml of deionized water. After mixing evenly, add 200 mg of carbon spheres, mix it ultrasonically, and then add 4 g of LiOH·H 2 O in 30ml deionized water, after stirring for 30min, add 10ml containing 0.7g SrCl 2 ·6H 2 O solution, after stirring for 30 minutes, the solution was transferred to a 100ml polytetrafluoroethylene reactor. The hydrothermal reaction temperature was 180°C, and the reaction time was 12 hours. Octahedral solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com