Method for evaluating reaction performance of carbon-iron composite furnace charge

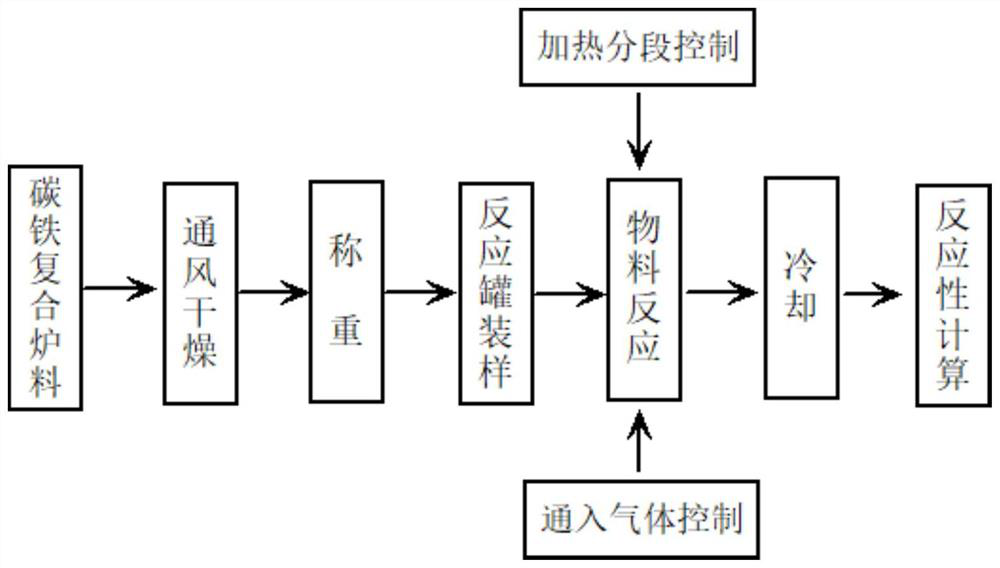

A technology of reaction performance and evaluation method, applied in the direction of removing certain components, such as weighing, etc., can solve the situation that the performance change of metallurgical coke cannot be truly reflected, the coke heating and reaction environment cannot be used, and it is not suitable for high-reactivity carbon-iron composite charge. Reaction performance and other issues, to ensure environmental and economic benefits, reduce blast furnace ironmaking production costs, and improve the effect of gas utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

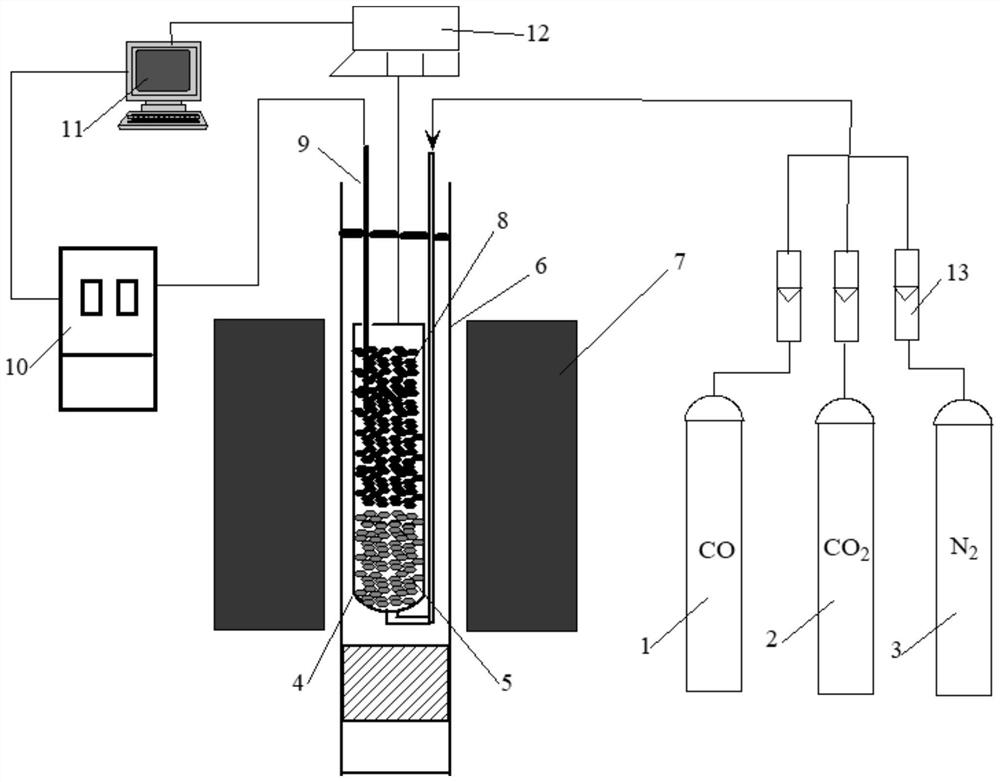

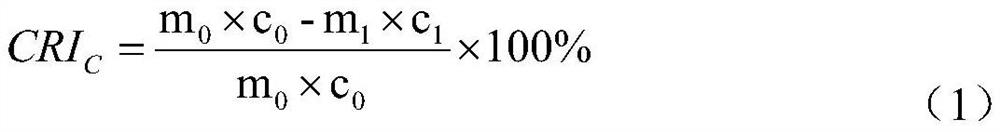

[0070] Ventilate and dry the carbon-iron composite charge with the original iron ore powder content of 0.5% and particle size of 25mm until the moisture content of the material is less than 1%. Sampling 400g(m 0 ) material 8 and measure the carbon content c of material 8 before the reaction 0 =99.2%, the material 8 is loaded into the reaction tank 4 with a certain amount of corundum balls 5 laid on the bottom, after the material 8 is installed, the reaction tank 4 is shaken to make the surface of the material 8 as smooth as possible, and then the cover on the top of the reaction tank 4 is installed. A temperature measuring thermocouple 9 is inserted into the top of the reaction tank 4, and the depth of the temperature measuring thermocouple 9 inserted into the material 8 is about 150 mm. The temperature measuring thermocouple 9 is connected to a computer 11 through a temperature controller 10. Put the entire reaction tank 4 into the corundum tube 6 in the heating furnace 7, a...

Embodiment 2

[0072] Ventilate and dry the carbon-iron composite charge with the original iron ore powder content of 10% and particle size of 20mm until the moisture content of the material is less than 1%. Sampling 370g(m 0 ) material 8 and measure the carbon content of material 8 before the reaction, c 0 =80.1%, put the material 8 into the reaction tank 4 with a certain amount of corundum balls 5 laid on the bottom, shake the reaction tank 4 after the material 8 is installed to make the surface of the material 8 as smooth as possible, and then install the cover on the top of the reaction tank 4. A temperature measuring thermocouple 9 is inserted into the top of the reaction tank 4, and the depth of the temperature measuring thermocouple 9 inserted into the material 8 is about 130mm. The temperature measuring thermocouple 9 is connected to a computer 11 through a temperature controller 10. Put the entire reaction tank 4 into the corundum tube 6 in the heating furnace 7, and hang it under ...

Embodiment 3

[0074] Ventilate and dry the carbon-iron composite charge with the original iron ore powder content of 20% and particle size of 15mm until the moisture content of the material is less than 1%. Sampling 350g(m 0 ) material 8 and measure the carbon content of material 8 before the reaction, c 0 =71%, material 8 is packed into the reaction tank 4 with a certain amount of corundum balls 5 laid on the bottom, shake the reaction tank 4 after the material 8 is installed to make the surface of the material 8 as smooth as possible, and then install the lid on the top of the reaction tank 4. A temperature measuring thermocouple 9 is inserted into the top of the reaction tank 4, and the depth of the temperature measuring thermocouple 9 inserted into the material 8 is about 120 mm. The temperature measuring thermocouple 9 is connected to a computer 11 through a temperature controller 10. Put the entire reaction tank 4 into the corundum tube 6 in the heating furnace 7, and hang it under t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com