Complete equipment matched with ammonia synthesis device

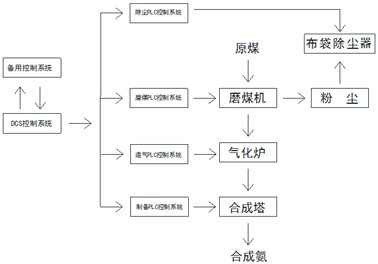

A technology for an ammonia synthesis device and a complete set of equipment, which is applied in the fields of ammonia preparation/separation, removal of smoke and dust, cleaning methods and utensils, etc., can solve problems such as difficulty in meeting production and use requirements, increased failure rate of operating computers, and hidden safety hazards in production systems, etc. Achieve the effect of eliminating the accidental hidden danger that cannot be automatically switched, eliminating adverse effects, and stable software operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

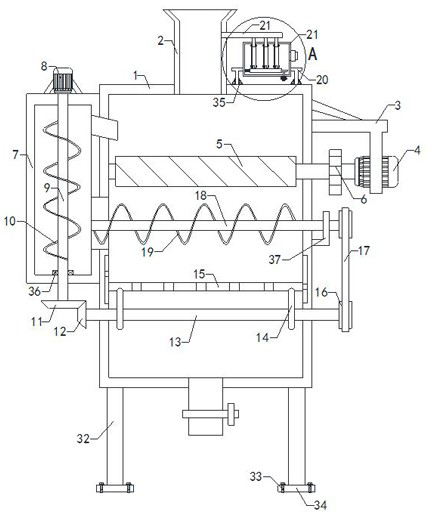

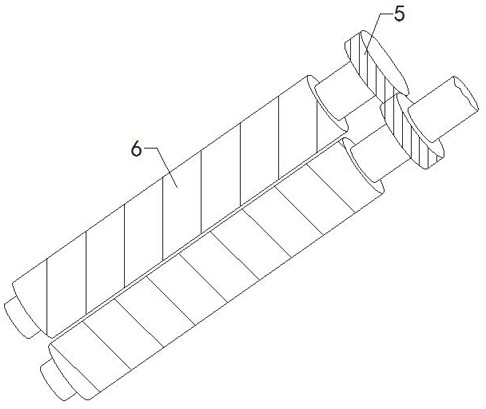

[0029]The coal mill includes a coal mill main body 1, a hopper 2, a fixed frame 3, a first motor 4, two sets of grinding rollers 5, two sets of gears 6, a storage box 7, a second motor 8, a first rotating shaft 9, The first helical blade 10, the first bevel gear 11, the second bevel gear 12, the second rotating shaft 13, two groups of first cams 14, the sieve plate 15, two groups of pulleys 16, belts 17, the third rotating shaft 18 and The second spiral blade 19 is provided with a chamber inside the main body 1 of the coal mill, and a discharge pipe is arranged at the bottom end. On the upper front side of the right end of the main body of the coal mill 1, the output end of the first motor 4 is connected to a set of grinding rollers 5, and the two sets of grinding rollers 5 are respectively connected in rotation to the front and rear sides of the upper part of the main body of the coal mill 1, and two sets of gears 6 They are respectively fixed on the right side of the two gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com