Preparation method of two-dimensional hybrid halide perovskite nanosheet

A halide perovskite and nanosheet technology, applied in the preparation of organic compounds, the preparation of amino compounds, organic chemistry methods, etc., can solve the problems of uncontrollable size and morphology, and achieve a very high confinement effect and purity. High and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

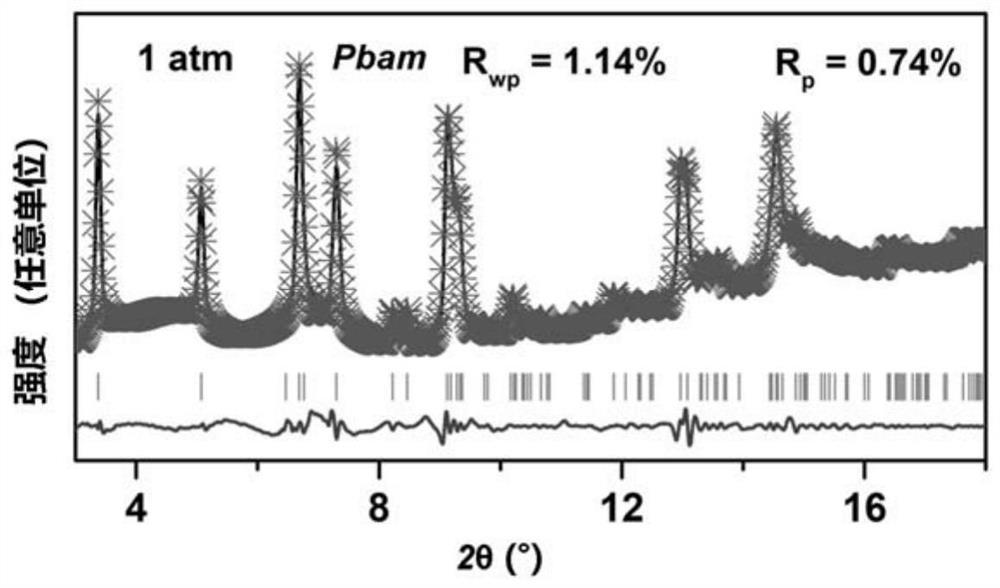

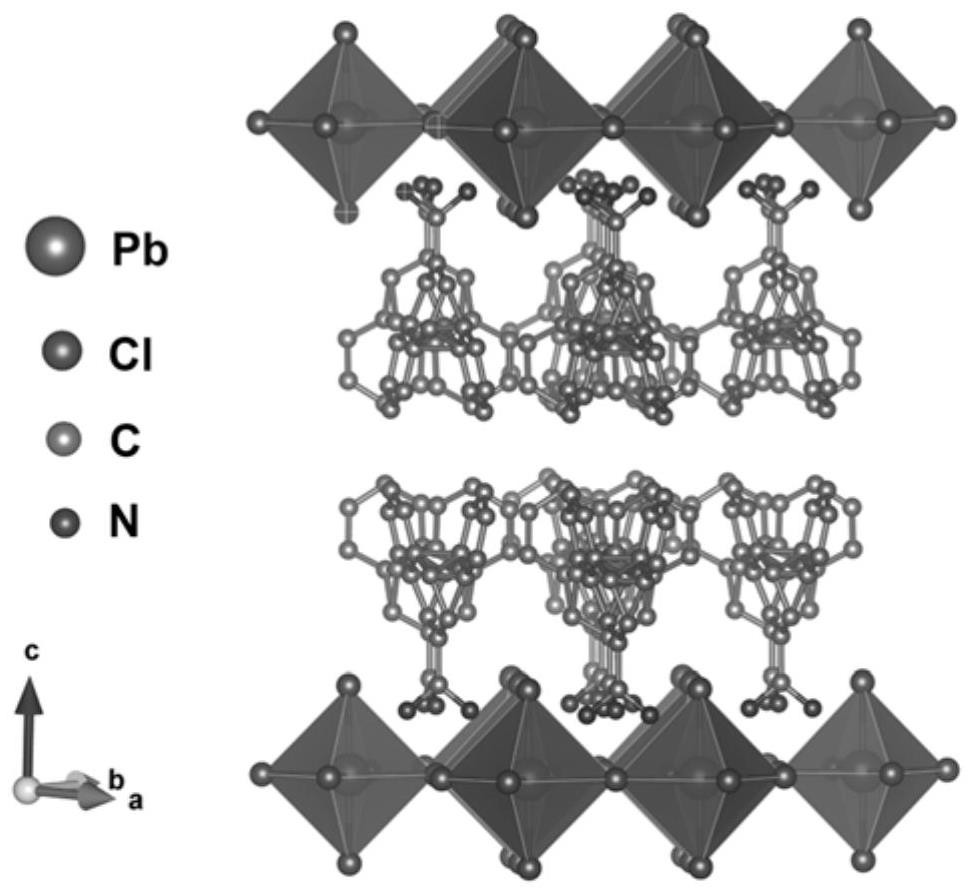

[0038] Example 1 (NAPH) 2 PBCL 4 Preparation of body materials

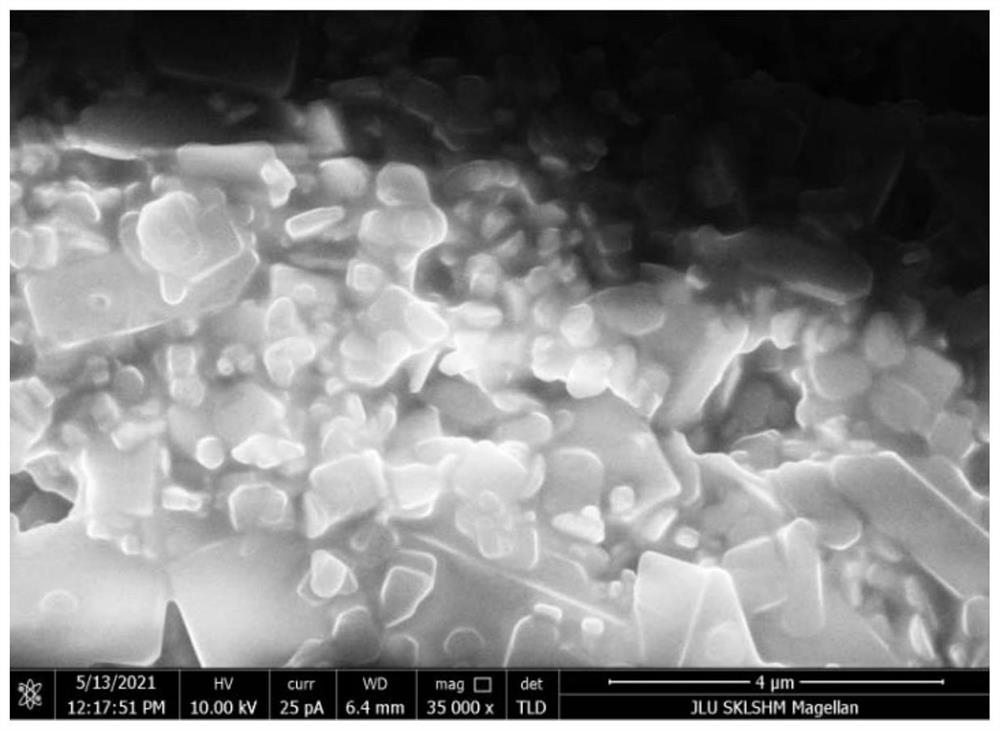

[0039] Chloride and 2-naphthyl-ammonium chloride were dissolved in dimethylformamide at 1: 2 molar ratio, so that the solution was slowly evaporated, and the colorless crystals were grown. Figure 3-5 Scale Bar is 4 μm and 3 μm and 500 nm scanning electron microscope photos. Can be clearly seen, (NAPH) 2 PBCL 4 The overall formation is very thick, which is difficult to reflect the size of the material.

Embodiment 2

[0040] Example 2 (NAPH) 2 PBCL 4 Micron sheet preparation

[0041] 0.2mmol NAPH, 0.1mmol PBCL 2 DMF (500 μL), 0.5 ml of HBR (a mass fraction of 40%, density of 1.38 g / ml, and the same) was placed in a 30 ml tapered bottle. The mixture was stirred at room temperature until the solution was clarified to form a precursor solution of a calcium titanium ore. Then, 200 μl of the precursor solution of 200 μl of titanium titanium ore was quickly dropped into 10 ml of n-hexane, and stirred vigorously. Finally, 2 mL of acetone is rapidly injected and stirred for 12 h, it is obtained from the anti-solvent method to obtain (NAPH) 2 PBCL 4 Micron sheet, Figure 6-7 Scale Bar is 40 μm and 4 μm scanning electron microscope photo. As can be seen from the figure, the thickness of the sheet is reduced relative to the body material, but there is no rule.

[0042] The above Examples 1, 2 is the control example, and the conventional antimodational method or the improved anti-solubility method is prep...

Embodiment 3

[0043] Example 3 (NAPH) 2 PBCL 4 Preparation of nano sheets

[0044] 0.2mmol NAPH, 0.1mmol PBCL 2 , DMF (500 μL), 0.5 ml of HBR, 2.65 μL of n-octamine was placed in a 30 ml tapered bottle. The mixture was stirred at room temperature until the solution was clarified to form a precursor solution of a calcium titanium ore. Then, 200 μl of the precursor solution of 200 μl of titanium titanium ore was quickly dropped into 10 ml of n-hexane, and stirred vigorously. Finally, by rapid injection of 2 ml of acetone and stirred for 2 h, the anti-solvent method is used. Figure 8 Scanning photos of a scales (Scale Bar) to 1 μm Transmission electron microscope. Using this method, it has been scanned under the transmission electron microscope, indicating that the thickness of the thin film is very thin, and is thinned (NAPH) 2 PBCL 4 Nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com