Preparation method for triphase mixed crystal titanium dioxide materials

A titanium dioxide and mixed technology, applied in the field of photocatalysis, can solve the problems of unfavorable popularization and application, complicated operation, high energy consumption, etc., and achieve good photocatalytic purification effect, small material particle size and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

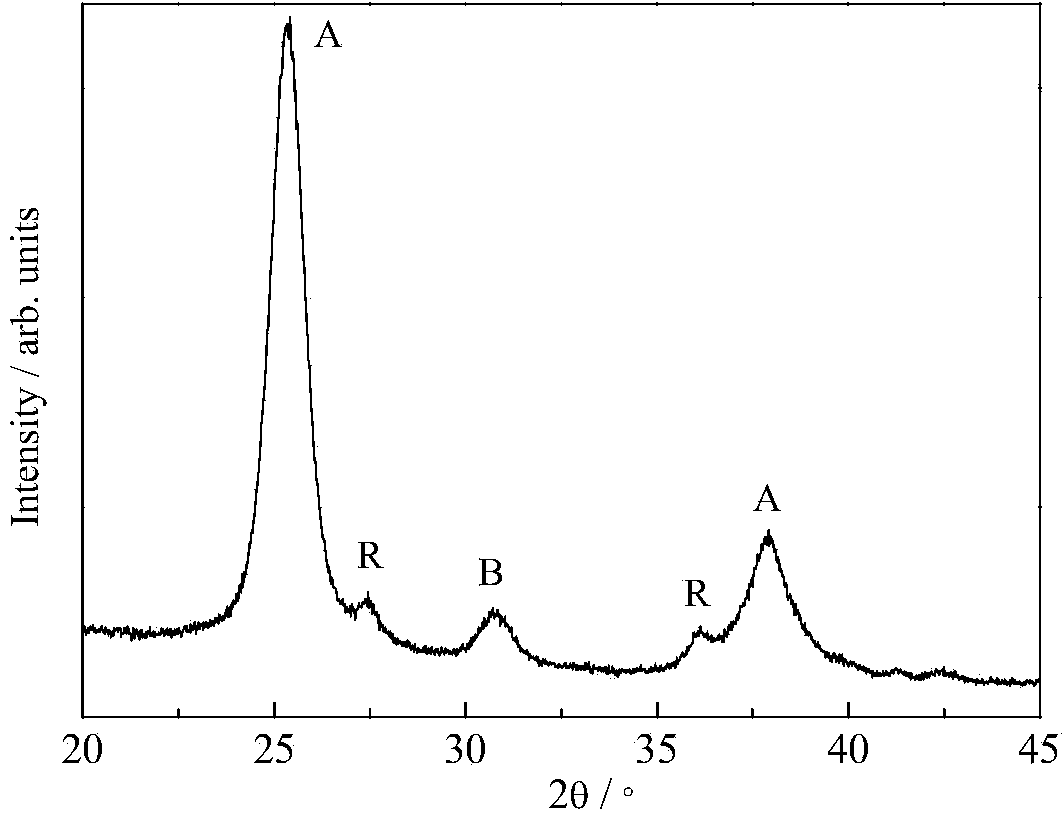

[0019] Add 4.4 mL of butyl titanate to 50 mL of 10 mol / L sodium hydroxide solution, and continue to stir for 5 h; wash the resulting precipitate with 150 mL of water three times, redisperse it in 40 mL of 0.25 mol / L nitric acid solution, and stir 30 min; the resulting mixture was placed in a 100 mL hydrothermal reaction kettle with a tetrafluoroethylene liner, and hydrothermally reacted at 180 °C for 24 h; the obtained precipitate was washed with water until the supernatant was neutral, and then dried at 50 °C. For details, please refer to figure 1 , figure 1 X-ray diffraction (XRD) pattern of the three-phase mixed crystal titanium dioxide prepared for this example.

Embodiment 2

[0021] Add 4.4 mL of isopropyl titanate to 50 mL of 10 mol / L sodium hydroxide solution, and continue to stir for 5 h; wash the obtained precipitate with 150 mL of water three times, and redisperse it in 40 mL of 0.25 mol / L hydrochloric acid solution. Stir for 30 min; put the obtained mixture in a 100 mL hydrothermal reaction kettle with a PTFE liner, and conduct a hydrothermal reaction at 180 °C for 24 h; wash the obtained precipitate with water until the supernatant is neutral, and dry it at 50 °C to obtain .

Embodiment 3

[0023] Add 4.4 mL of butyl titanate to 100 mL of 8 mol / L potassium hydroxide solution, and continue to stir for 5 h; wash the resulting precipitate with 150 mL of water three times, redisperse it in 40 mL of 0.25 mol / L hydrochloric acid solution, and stir 30 min; the resulting mixture was placed in a 100 mL hydrothermal reaction kettle with a tetrafluoroethylene liner, and hydrothermally reacted at 180 °C for 24 h; the obtained precipitate was washed with water until the supernatant was neutral, and then dried at 50 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com