Preparation method of medium-low voltage water tree resistant cable insulating material

A cable insulation and low voltage technology, which is applied in the field of preparation of medium and low voltage waterproof tree cable insulation materials, can solve the problems of reduced mechanical properties of the effective insulating layer, and achieve the effects of shortening the processing cycle, improving hydrophilicity, and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] In the embodiment of the present invention, a method for preparing medium and low voltage waterproof tree cable insulation materials includes the following steps: Step 1: configuring raw materials according to the mass fraction ratio, the raw materials are composed of A material and B material, and the A material includes 100 Parts of polyethylene, 15-27 parts of anti-water tree graft polymer, 5-20 parts of nano inorganic nucleating agent and 1.5-3 parts of carbon quantum dot nucleating agent, the B material includes 100 parts of poly Ethylene base resin, 0.5-5 parts of crosslinking agent and 0.5-3 parts of auxiliary crosslinking agent; step 2: nucleating polyethylene, anti-water tree graft polymer, nano inorganic nucleating agent and carbon quantum dots According to the metering ratio, blend at low speed in a high-speed mixer at room temperature for a certain period of time, then extrude and granulate material A with twin-screw at a certain temperature; step 3: mix poly...

Embodiment 1

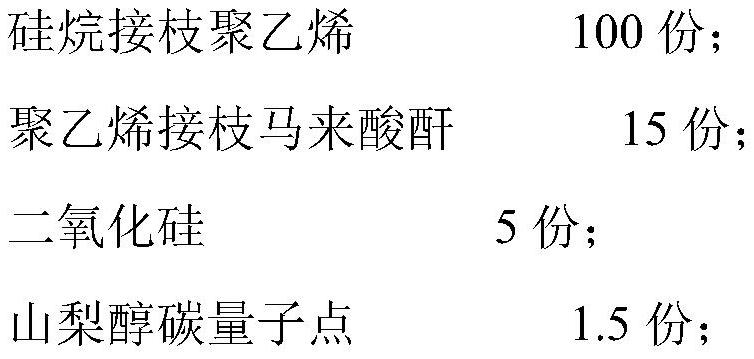

[0020] A medium and low voltage waterproof tree cable insulation material, comprising the following raw materials in parts by weight:

[0021] Material A:

[0022]

[0023] Material B:

[0024] 100 parts of low-density polyethylene (LDPE);

[0025] 0.5 parts of dicumyl peroxide (DCP);

[0026] 0.5 part of vinyltriethoxysilane;

[0027] The weight ratio of material A and material B is 2:5.

[0028] The cable insulating material is obtained by melt-blending material A and material B at 60° C. with twin-screws, extruding and granulating.

Embodiment 2

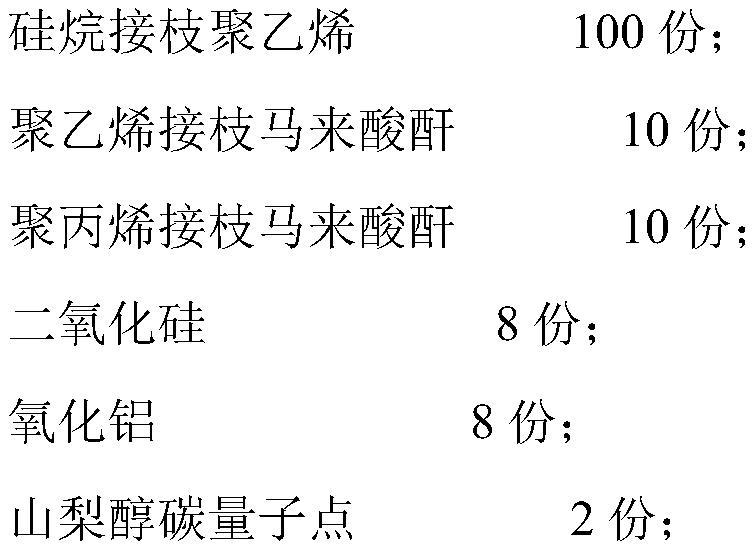

[0030] A medium and low voltage waterproof tree cable insulation material, comprising the following raw materials in parts by weight:

[0031] Material A:

[0032]

[0033] Material B:

[0034]

[0035] The weight ratio of material A and material B is 2:5.

[0036] The cable insulating material is obtained by melt-blending material A and material B at 80°C with twin-screws, extruding and granulating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com