PC/ABS composite material and preparation method thereof, blow mold and blow molding method

A technology of composite materials and blow molding molds, which is applied in the field of blow molding molds, PC/ABS composite materials and their preparation, and can solve the problems of poor flame retardant effect of PC/ABS composite materials, rough surface of blow molding products, and poor demoulding effect and other problems, to achieve the effect of improving processing fluidity, improving mechanical properties, increasing elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

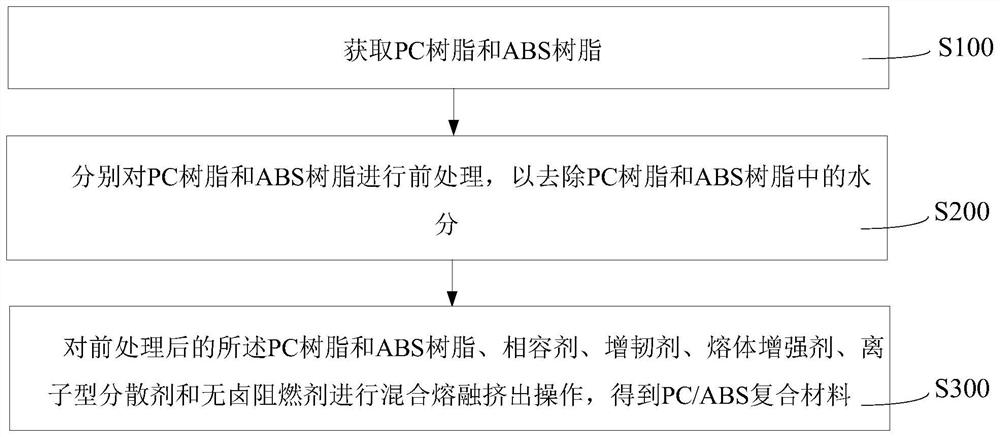

[0052] The present application also provides a preparation method of a PC / ABS composite material, which is used to prepare the PC / ABS composite material of any of the above embodiments. The preparation method of the above-mentioned PC / ABS composite material comprises the following steps: obtaining PC resin and ABS resin; respectively pre-processing the PC resin and the ABS resin to remove the moisture in the PC resin and the ABS resin; Mixing melt extrusion with ABS resin, compatibilizer, toughening agent, melt reinforcing agent, ionic dispersant and halogen-free flame retardant to obtain PC / ABS composite material.

[0053] In the above-mentioned preparation method of PC / ABS composite material, PC resin and ABS resin are pre-treated to reduce the moisture contained in PC resin and ABS resin, and the melt extrusion effect of PC / ABS composite material is ensured. The PC resin and ABS resin, compatibilizer, toughening agent, melt enhancer, ionic dispersant and halogen-free flame ...

Embodiment 1

[0096] Obtain 25kg of PC resin; 70kg of ABS resin; 3kg of compatibilizer; 2kg of toughening agent; 1kg of melt enhancer; 1kg of ionic dispersant; 8kg of halogen-free flame retardant;

[0097] Add PC resin, ABS resin, ionic dispersant and halogen-free flame retardant in the front section of the screw extruder for melt extrusion, then add the toughener, melt enhancer and compatibilizer in the middle section of the screw extruder Carry out melt extrusion and granulation to obtain PC / ABS composite material;

[0098] The PC / ABS composite material is prepared as a parison to obtain a parison;

[0099] The parison is placed in a blow mold for hot air and cold air blow molding, and the mold is demolded to obtain a PC / ABS composite product.

Embodiment 2

[0101] Obtain 26kg of PC resin; 72kg of ABS resin; 4kg of compatibilizer; 4kg of toughening agent; 2kg of melt enhancer; 2kg of ionic dispersant; 10kg of halogen-free flame retardant;

[0102] Add PC resin, ABS resin, ionic dispersant and halogen-free flame retardant to the front section of the screw extruder for melt extrusion and granulation to obtain the semi-finished product of PC / ABS composite material;

[0103] The PC / ABS composite material semi-finished product, toughening agent, melt reinforcing agent and compatibilizer are added in the front section of the screw extruder for melt extrusion and granulation to obtain the PC / ABS composite material;

[0104] The PC / ABS composite material is prepared as a parison to obtain a parison;

[0105] The parison is placed in a blow mold for hot air and cold air blow molding, and the mold is demolded to obtain a PC / ABS composite product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com