A kind of pre-hydrolyzed organosilicon precursor composition for stone protection and preparation method thereof

A composition and pre-hydrolysis technology, applied in the direction of coating, etc., can solve the problems of poor storage stability and protective effect, achieve long-term protective effect, accelerate curing speed, and improve hydrophobic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

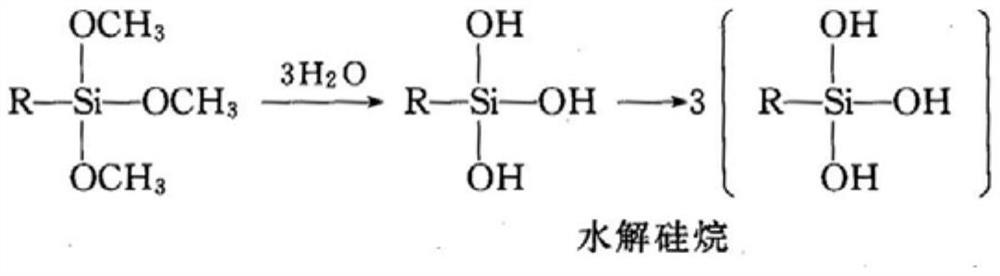

Method used

Image

Examples

Embodiment 1

[0032] Preparation of pre-hydrolyzed organosilicon precursor composition, the method is as follows:

[0033] First, 40 parts by weight of deionized water was prepared in the reaction kettle, and 10 parts by weight of ethylene glycol and 30 parts by weight of diethanolamine were sequentially added during stirring, mixed uniformly, and heated to 70° C. to obtain material A.

[0034] Second, 10 parts by weight of aminosilane and 5 parts by weight of titanate were slowly added dropwise, and the mixture was refluxed at 65° C. for 1 hour until the material was clear to obtain material B.

[0035] Third, slowly pump in 40 parts by weight of a composite alkyl silane coupling agent, which is composed of methyltrimethoxysilane, dimethyldimethoxysilane and hexamethyldisiloxane, The weight ratio is 7:2:1, prepared by mixing in advance, heating the system to 70°C and refluxing for 1 hour. Then, it was transferred to rotary evaporation, and the temperature was raised to 80° C. and kept for...

Embodiment 2

[0039] Preparation of pre-hydrolyzed organosilicon precursor composition, the method is as follows:

[0040] First, 60 parts by weight of deionized water was prepared in the reaction kettle, and 20 parts by weight of ethylene glycol and 50 parts by weight of diethanolamine were sequentially added during stirring, mixed uniformly, and heated to 70° C. to obtain material A.

[0041] Second, 15 parts by weight of aminosilane and 10 parts by weight of titanate were slowly added dropwise, and the mixture was refluxed at 65° C. for 1 hour until the material was clear to obtain material B.

[0042]Third, slowly pump 60 parts by weight of a composite alkyl silane coupling agent, which is composed of methyltrimethoxysilane, dimethyldimethoxysilane and hexamethyldisiloxane, The weight ratio is 7:2:1, prepared by mixing in advance, heating the system to 70°C and refluxing for 1 hour. Then, it was transferred to rotary evaporation, and the temperature was raised to 80° C. and kept for 1 ...

Embodiment 3

[0046] Preparation of pre-hydrolyzed organosilicon precursor composition, the method is as follows:

[0047] First, 50 parts by weight of deionized water was prepared in the reaction kettle, and 15 parts by weight of ethylene glycol and 40 parts by weight of diethanolamine were sequentially added during stirring, mixed uniformly, and heated to 70° C. to obtain material A.

[0048] Second, 10 parts by weight of aminosilane and 5 parts by weight of titanate were slowly added dropwise, and the mixture was refluxed at 65° C. for 1 hour until the material was clear to obtain material B.

[0049] Third, slowly pump in 50 parts by weight of a composite alkyl silane coupling agent, the composite alkyl silane coupling agent is composed of methyltrimethoxysilane, methyldimethoxysilane and hexamethyldisiloxane. The ratio is 7:2:1, prepared by mixing in advance, heating the system to 70°C and refluxing for 1 hour. Then, it was transferred to rotary evaporation, and the temperature was ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com