Preparation method of high-SERS-intensity Ag/SiO2 co-sputtering single-layer film

A co-sputtering, single-layer film technology, used in sputtering, coating, Raman scattering, etc., can solve the problems of insufficient sensitivity and measurement speed, limited SERS strength of single-layer metal film, etc., to improve the SERS strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

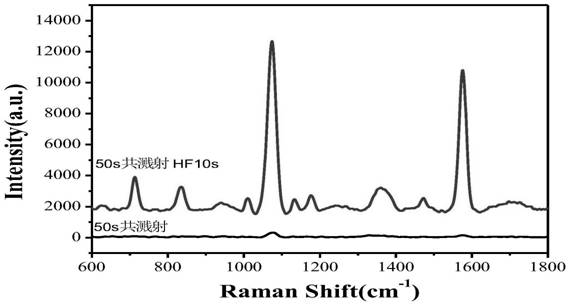

Embodiment 1

[0028] (1) Hydrophilic treatment of silicon wafers: place the cleaned silicon wafers in a beaker, add ammonia water, hydrogen peroxide and deionized water to the mixed solution, in the mixed solution, the volume of ammonia water, hydrogen peroxide and deionized water The ratio is 1:2:6, keep boiling for 10-15 minutes after boiling, pour out the mixed solution after cooling, and use deionized water and absolute ethanol to repeatedly ultrasonicate the silicon wafer for 10 minutes; the silicon wafer after cleaning is made by the following steps Obtained: Soak clean silicon wafers in deionized water and absolute ethanol respectively, and ultrasonically treat them.

[0029] (2) Preparation of Ag / SiO 2 Co-sputtering single-layer film: tilt the silver target and silicon dioxide target at 40° respectively, and sputter to the silicon wafer at the same time to generate Ag / SiO on the surface of the silicon wafer 2 Co-sputtered monolayer film; the background pressure before starting is 4...

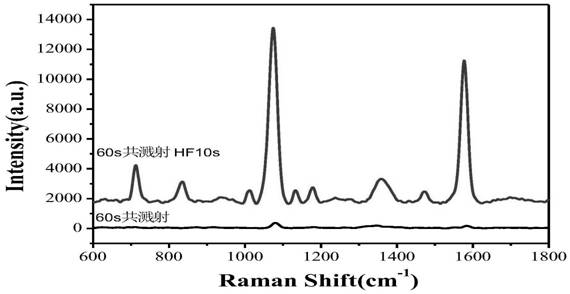

Embodiment 2

[0033] (1) Hydrophilic treatment of silicon wafers: place the cleaned silicon wafers in a beaker, add ammonia water, hydrogen peroxide and deionized water to the mixed solution, in the mixed solution, the volume of ammonia water, hydrogen peroxide and deionized water The ratio is 1:2:6, keep boiling for 10-15 minutes after boiling, pour out the mixed solution after cooling, and use deionized water and absolute ethanol to repeatedly ultrasonicate the silicon wafer for 12 minutes; the silicon wafer after cleaning is made by the following steps Obtained: Soak clean silicon wafers in deionized water and absolute ethanol respectively, and ultrasonically treat them.

[0034] (2) Preparation of Ag / SiO 2 Co-sputtering single-layer film: tilt the silver target and silicon dioxide target at 40° respectively, and sputter to the silicon wafer at the same time to generate Ag / SiO on the surface of the silicon wafer 2 Co-sputtered monolayer film; the background pressure before starting is 4...

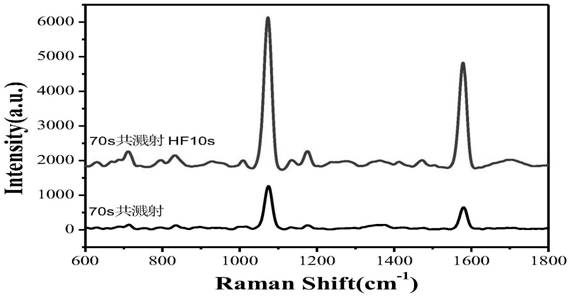

Embodiment 3

[0038](1) Hydrophilic treatment of silicon wafers: place the cleaned silicon wafers in a beaker, add ammonia water, hydrogen peroxide and deionized water to the mixed solution, in the mixed solution, the volume of ammonia water, hydrogen peroxide and deionized water The ratio is 1:2:6. After boiling, keep boiling for 10-15 minutes. After cooling, pour out the mixed solution, and use deionized water and absolute ethanol to repeatedly sonicate the silicon wafer for 15 minutes; the silicon wafer after cleaning is prepared by the following steps: Obtained: Soak clean silicon wafers in deionized water and absolute ethanol respectively, and ultrasonically treat them.

[0039] (2) Preparation of Ag / SiO 2 Co-sputtering single-layer film: tilt the silver target and silicon dioxide target at 40° respectively, and sputter to the silicon wafer at the same time to generate Ag / SiO on the surface of the silicon wafer 2 Co-sputtered monolayer film; the background pressure before starting is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com