Multi-unit multi-mode heat supply power plant operation comprehensive evaluation method based on fuzzy analysis

A comprehensive evaluation and technology for heating power plants, applied in multi-objective optimization, complex mathematical operations, computer-aided design, etc., can solve the problem of inability to accurately know the intelligent quantitative operation scheduling decision at the plant level of peak-shaving thermal power plants, and the optimization indicators and constraints are complex, It is difficult to comprehensively evaluate and other problems to achieve the effect of ensuring economic and environmental protection operation, large peak shaving benefits, and reducing deviations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

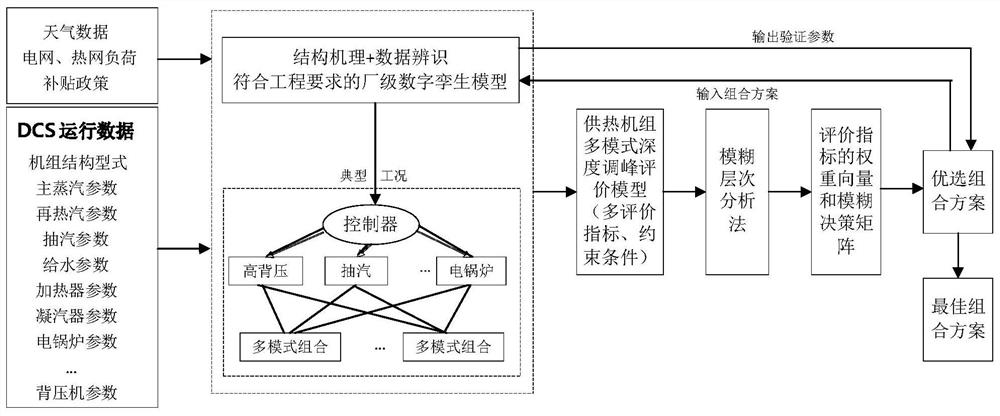

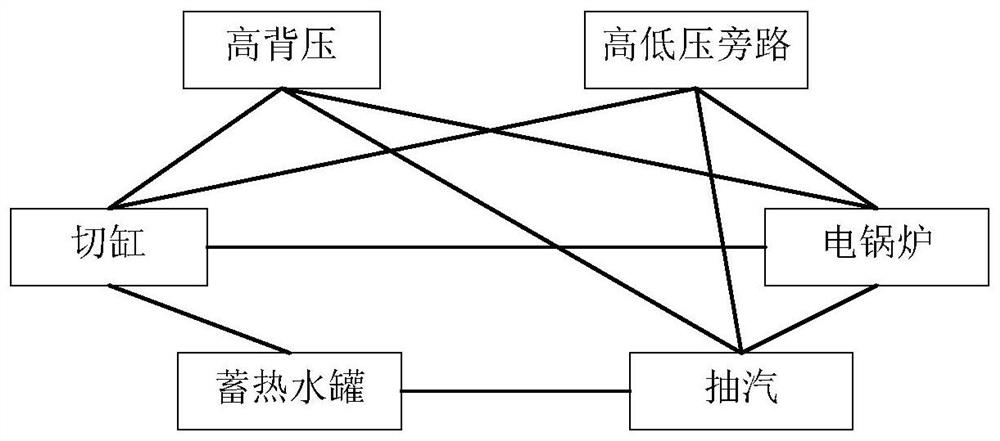

[0098] figure 1 It is a schematic diagram of the principles of the fuzzy analysis-based multi-unit and multi-mode thermal power plant operation comprehensive evaluation method involved in the present invention.

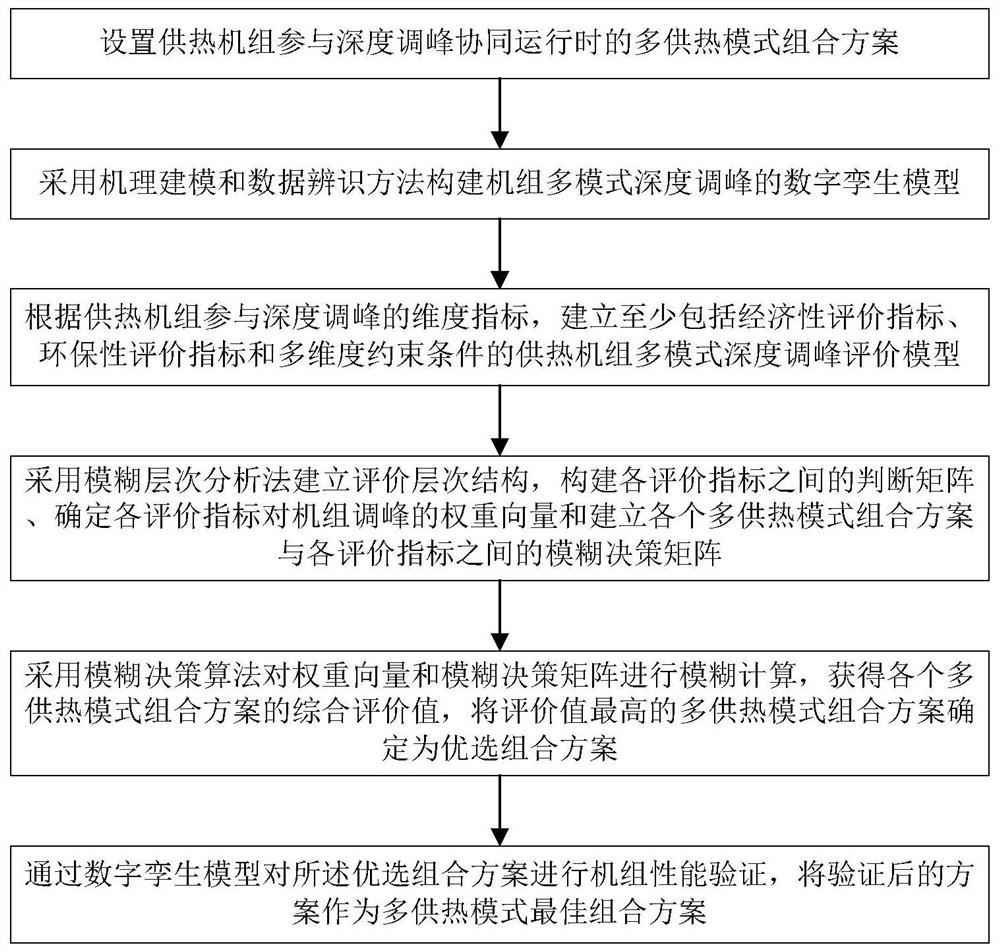

[0099] figure 2 It is a flow chart of the fuzzy analysis-based multi-unit multi-mode heat supply power plant operation comprehensive evaluation method involved in the present invention.

[0100] Such as figure 1 , figure 2 As shown, this embodiment 1 provides a fuzzy analysis-based comprehensive evaluation method for the operation of a multi-unit multi-mode heating power plant. The comprehensive evaluation method includes:

[0101] Step S1, setting the multi-heating mode combination plan when the heating unit participates in the coordinated operation of deep peak regulation;

[0102] Step S2, using mechanism modeling and data identification methods to construct a digital twin model for multi-mode deep peak regulation of units;

[0103] Step S3, according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com