Production method of low-resistance test coil circuit board

A production method and a technology for testing coils, which are applied in the field of circuit board manufacturing, can solve problems such as resistance fluctuations, coil short circuits, and failure to measure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

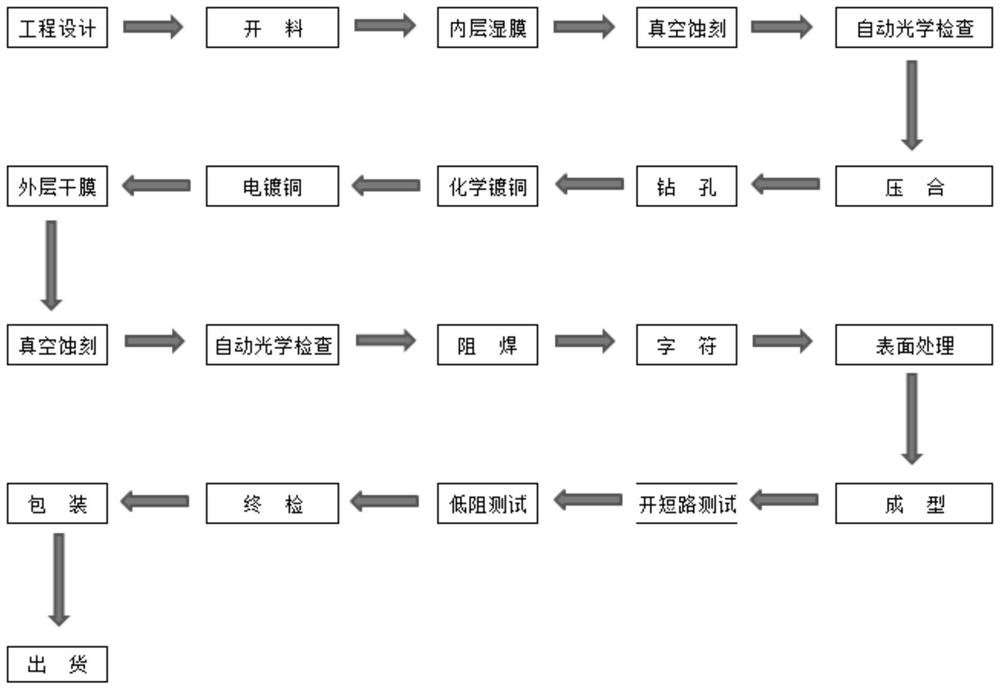

[0015] The invention provides a low-resistance test coil circuit board method, which performs special control on the coil during the production process, including engineering design, graphic transfer, graphic etching and silk screen printing of solder mask, to ensure that the line width / distance of the coil part is qualified , there is no short circuit, residual copper, no scratches, and the final resistance test meets customer requirements. The coil circuit board produced by the above method passes the low resistance test and can meet customer or IPC standards.

[0016] The present invention controls the following key technical points, thereby solving corresponding technical problems:

[0017] (1), engineering design

[0018] A. For the line film with coil, other areas can be compensated normally when the film is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com