Glass fiber drawing furnace and method for preparing glass fiber by using same

A glass fiber and wire drawing furnace technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as uneven temperature field, and achieve the effects of improving melting quality, improving stability, and uniform temperature field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

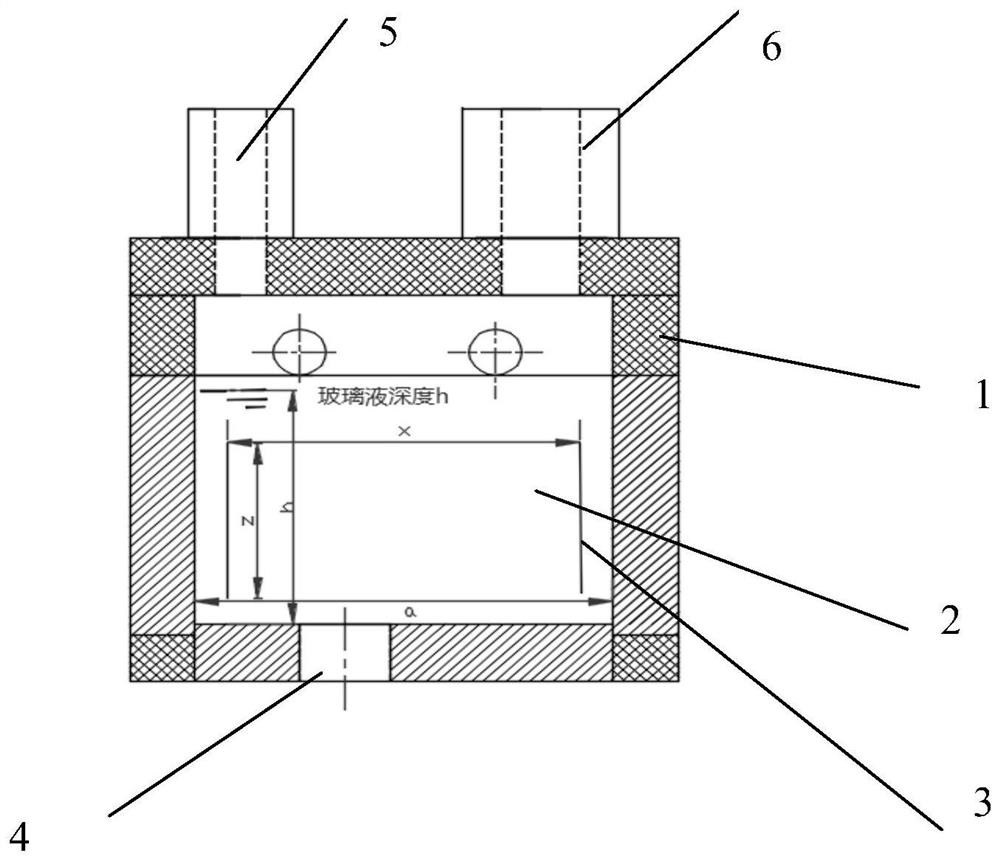

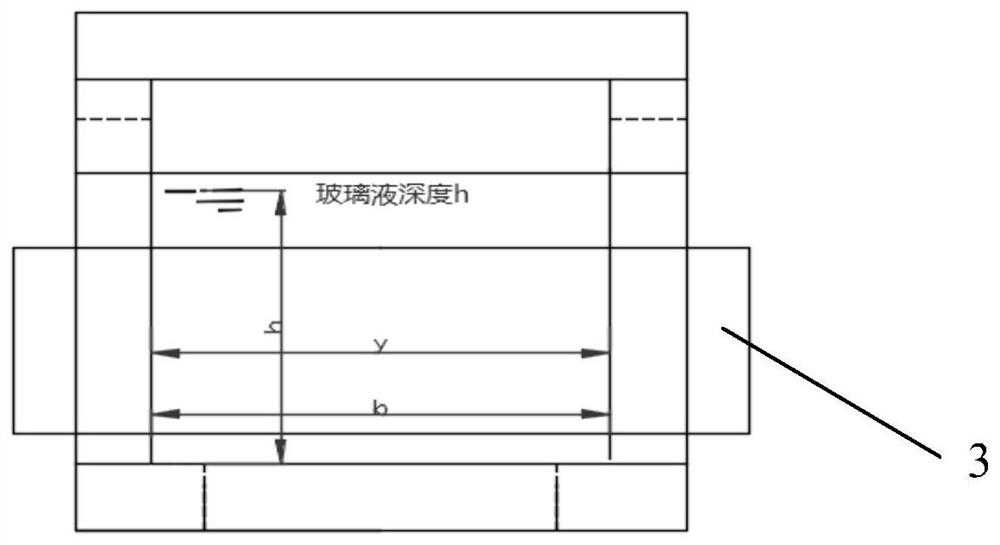

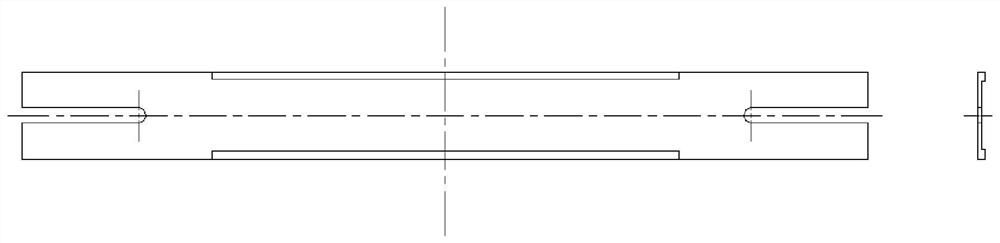

[0041] This embodiment provides a wire drawing furnace, such as Figure 1-3 As shown, the furnace body 1 is provided with a furnace 2 for accommodating molten glass, the top of the furnace body is provided with a ball adding hole 5 and a temperature measuring hole 6 , and the bottom of the furnace body is provided with a liquid flow hole 4 . The side wall, bottom brick and top brick of the furnace body in the present invention can all adopt existing brick bodies, such as but not limited to at least one of corundum bricks and zircon bricks, preferably dense zircon bricks or high zircon bricks. Two electrode plates 3 are arranged in the furnace, and the electrode plates can be conventional electrode plates such as platinum electrodes, and the two electrode plates have the same size. The two electrode plates are arranged in a direction perpendicular to the wire-drawing furnace bottom bricks, and the two electrode plates are arranged parallel and side by side.

[0042] Wherein, t...

Embodiment 2

[0055] This embodiment provides a wire drawing furnace, which differs from Embodiment 1 only in the parameters of the wire drawing furnace. The parameters of the wire drawing furnace in this embodiment are shown in Table 2.

[0056] Table 2 Dimensions of Drawing Furnace in Embodiment 2

[0057]

[0058] The volume of the molten glass covered by the electric force line is 0.45 times the volume of the molten glass (denoted as xyz / abh). The conductive area of the electrode plate is 0.54 times the conductive cross-sectional area of the glass liquid (denoted as yz / bh).

[0059] This embodiment also provides a method for preparing glass fibers, comprising the following steps: taking alkali-free glass balls and putting the alkali-free glass balls into each drawing furnace according to the depth of the glass liquid in this embodiment, energizing and heating up, and the hot spot temperature is Drawing is carried out at 1340°C to obtain glass fibers.

Embodiment 3

[0061] This embodiment provides a wire drawing furnace, which differs from Embodiment 1 only in that the length of the flow hole is 180 mm, and the length of the electrode is 1.7 times the length of the flow hole.

[0062] This embodiment also provides a method for preparing glass fibers, comprising the following steps: taking alkali-free glass balls and putting the alkali-free glass balls into each drawing furnace according to the depth of the glass liquid in this embodiment, energizing and heating up, and the hot spot temperature is Drawing is carried out at 1330°C to obtain glass fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com