Integrally-formed high-molecular plastic oil-water separator and mold

A water separator and separator technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor transportation safety, uneven defective rate and defect rate, low production efficiency, etc., and achieve high-strength mechanical Performance, time cost reduction, labor cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

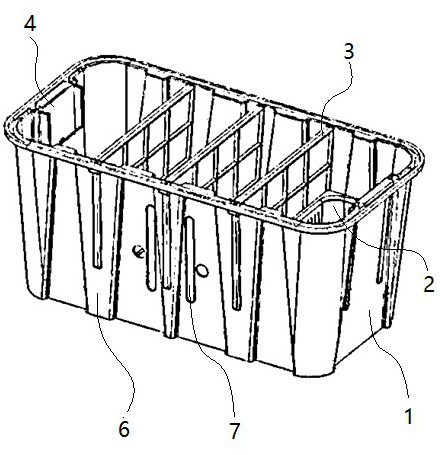

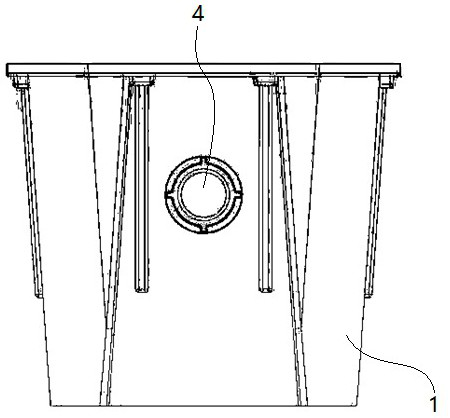

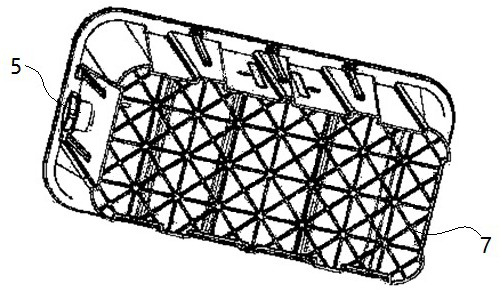

[0017] In order to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, see Figure 1 to Figure 4 .

[0018] The integrally formed polymer plastic oil-water separator implemented by the present invention includes a separator body, a filter plate, a filter basket, and a top plate. The separator body, filter plate, and top plate are all integrally injection-molded by polymer plastics. It is a mixture of oil and salt. In order to ensure the stability of the separator, no electrochemical reaction will occur. The polymer plastic of the separator body, filter plate, filter basket and top plate is 80% high-density polypropylene, EPDM6%, anti-ultraviolet UV4%, POE4%, and antioxidant 6% are extruded through high-speed banburying process. This material has the characteristics of corrosion resistance, aging resistance, and cold resistance, which grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com