Blue light and infrared dual-wavelength coaxial composite laser additive manufacturing device and method

A technology of laser additive manufacturing and manufacturing equipment, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency. It can solve problems such as reducing the density of molded parts, powder adhesion on the surface of molded parts, and affecting molding accuracy and surface roughness. , to reduce the temperature gradient of the molten pool, reduce the surface roughness, and improve the molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

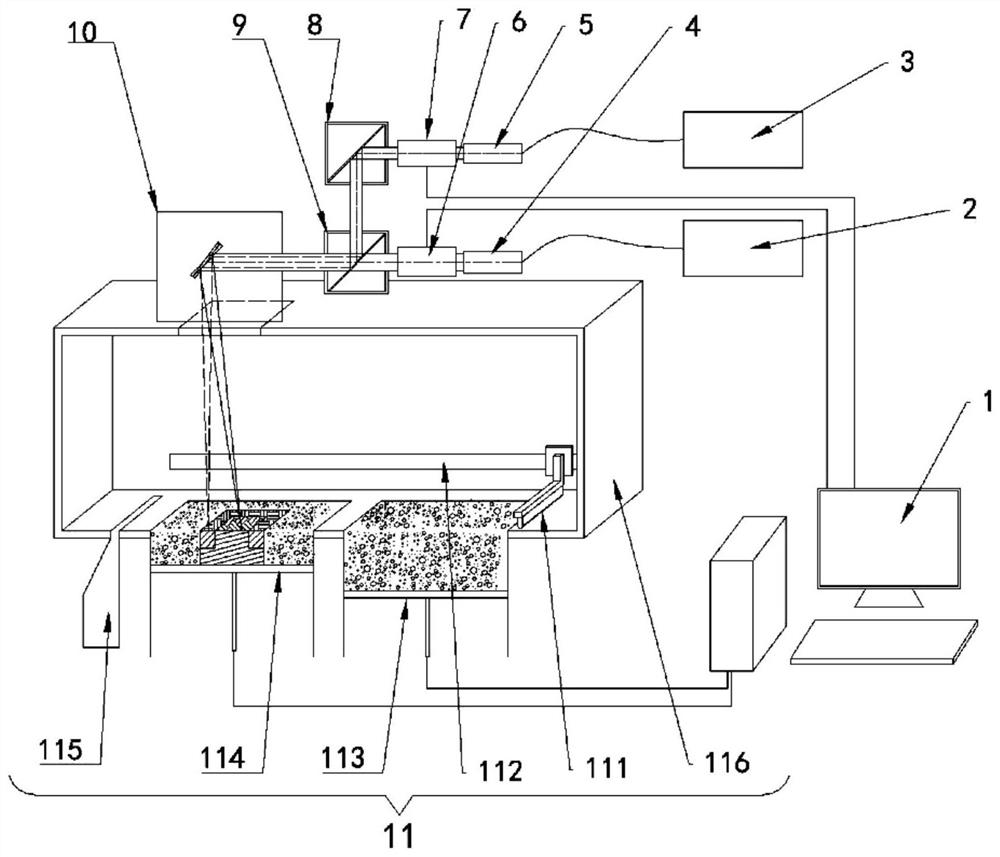

[0045] Such as Figure 1-3 shown. The invention discloses a blue-light infrared dual-wavelength coaxial composite laser additive manufacturing device, which includes a computer system 1, a molding cavity 11 and a laser;

[0046] The laser includes: an infrared laser 2, a blue laser 3, an infrared collimator 4, a blue collimator 5, an infrared dynamic focusing mirror 6, a blue dynamic focusing mirror 7, a blue reflector 8, a beam combiner 9, a scanning Galvanometer 10;

[0047] The infrared laser 2, the infrared light collimating mirror 4, the infrared light dynamic focusing mirror 6, the beam combiner 9 and the scanning vibrating mirror 10 are sequentially connected in an optical path;

[0048] The blue light laser 3, the blue light collimator 5, the blue light dynamic focusing mirror 7, the blue light reflector 8, the beam combiner 9 and the scanning vibrating mirror 10 are sequentially connected in an optical path.

[0049] The beam combiner 9 is a dichroic mirror, one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com