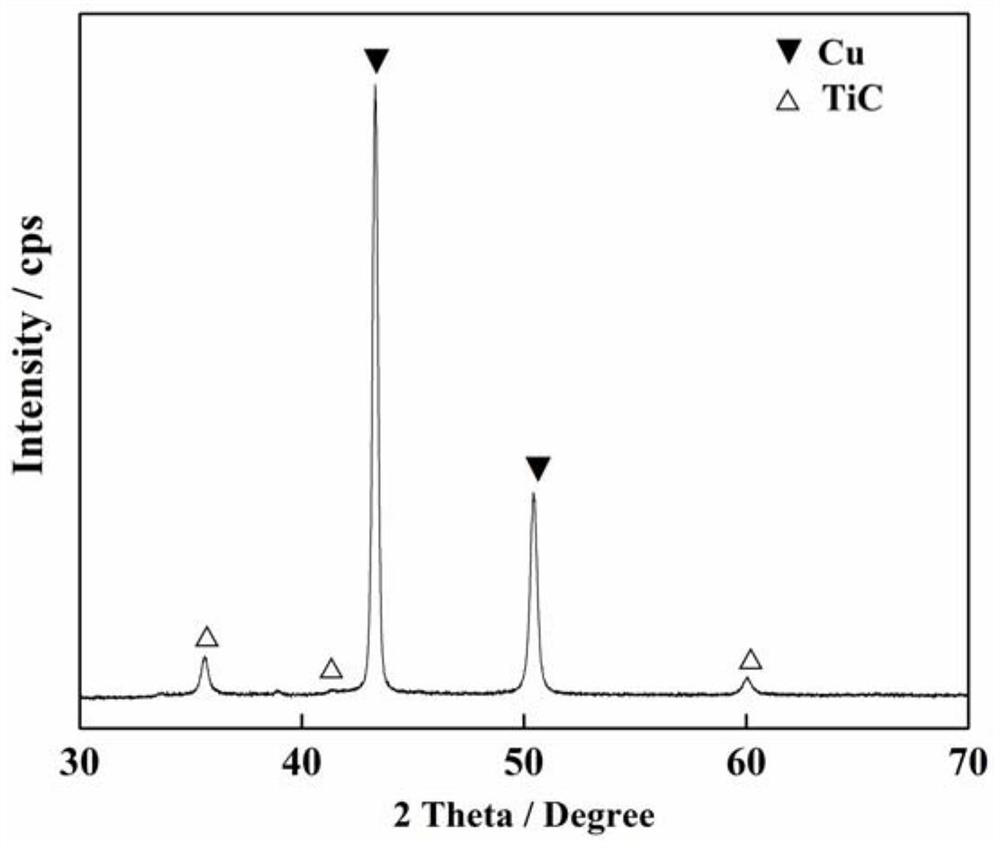

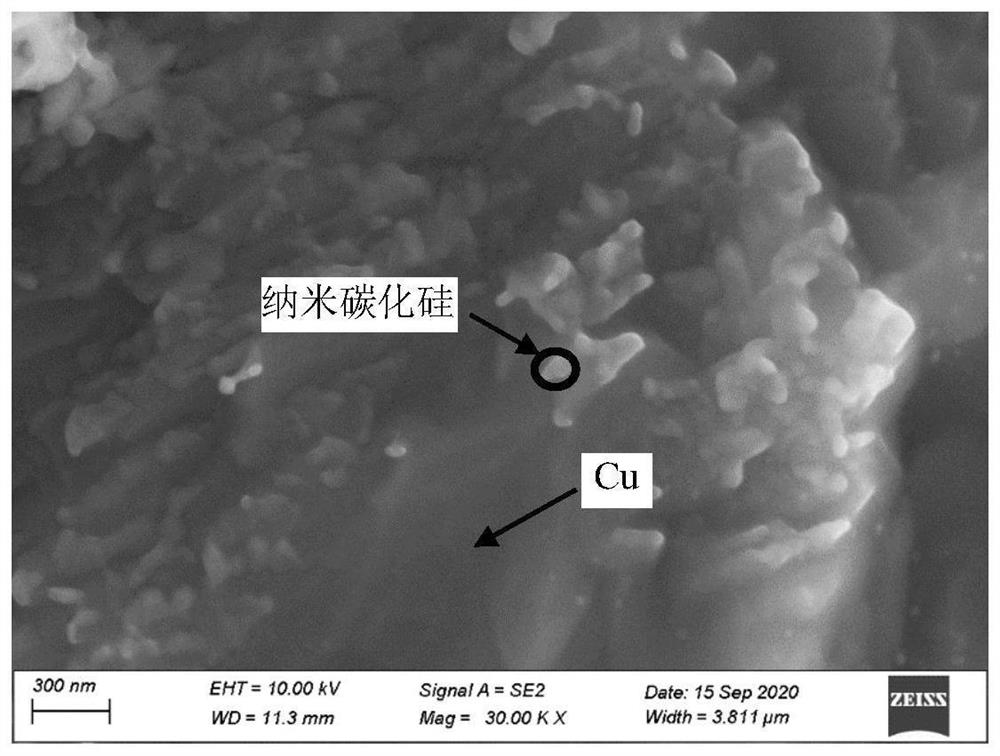

Nano silicon carbide particle reinforced copper-based spherical metal powder suitable for 3D printing and preparation method thereof

A nano-silicon carbide and particle-reinforced technology, applied in the field of additive manufacturing materials, can solve the problems of high-temperature strength, poor wear resistance, high reflection, and difficult printing of pure copper materials, and achieve high use temperature, simple process, and reduce difficult printing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] An embodiment of the present invention provides a method for preparing a nano-silicon carbide particle-reinforced copper-based spherical metal powder suitable for 3D printing. The method specifically includes the following steps:

[0036] S1: Weigh the raw materials comprising nano-silicon carbide, copper powder and inorganic salt in proportion, place the raw materials on a mixer for ball milling, wherein the volume ratio of the sum of the volumes of copper powder and nano-silicon carbide to the inorganic salt is 3: 97~15:85, and the volume ratio of nano silicon carbide and copper powder is 0.1:1~1:1;

[0037] S2: Sieve the ball-milled mixture to obtain a raw material powder containing copper powder, nano-silicon carbide and inorganic salt;

[0038] S3: placing the raw material powder obtained in step S2 in a vacuum melting furnace for heating and melting, ultrasonically dispersing the melt and then cooling it;

[0039] S4: crushing the cooled massive solid, the partic...

Embodiment 1

[0062] The preparation method of nano-silicon carbide particle-reinforced copper-based spherical metal powder suitable for 3D printing in this embodiment specifically includes the following steps:

[0063] S1: Weigh the raw materials composed of nano-silicon carbide, copper powder and potassium chloride in proportion, the average particle diameter of nano-silicon carbide is 50nm, the average particle diameter of copper powder is 45 μm, and the average particle diameter of described potassium chloride is 500μm, the volume ratio of nano-silicon carbide, copper powder and potassium chloride is 4.44:5.56:90, put the raw materials into the mixing bottle in the glove box protected by argon, and add zirconia grinding balls into the mixing bottle Sealing, wherein the mass ratio of grinding balls and raw materials is 4:1; the sealed mixing bottle is placed on a mixer for ball milling, the ball milling time is 24h, and the ball mill rotating speed is 300r / min;

[0064] S2: Sieve the bal...

Embodiment 2

[0071] The preparation method of nano-silicon carbide particle-reinforced copper-based spherical metal powder suitable for 3D printing in this embodiment is basically the same as that of Example 1, the difference is that in step S1 of this embodiment, the raw materials are composed of nano-silicon carbide, copper powder and Potassium chloride composition, wherein, the average particle diameter of nano-silicon carbide is 50nm, the average particle diameter of copper powder is 80 μ m, the average particle diameter of described potassium chloride is 500 μ m, the volume of nano-silicon carbide, copper powder and potassium chloride The ratio is 4.44:5.56:90.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com