Negative motor hydraulic combined brake control system of bidirectional driving electric forklift

A technology of combined braking and two-way driving, which is applied in electric vehicle charging technology, brakes, control drive, etc., can solve the problems of large maintenance, low reliability, complicated system, etc., so as to improve service life, improve safety, reduce The effect of small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

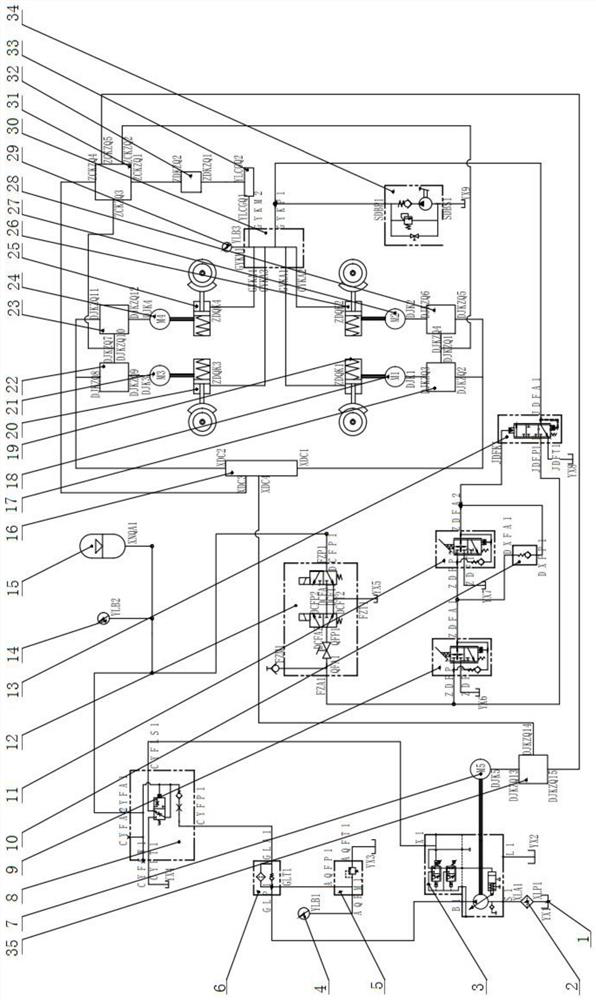

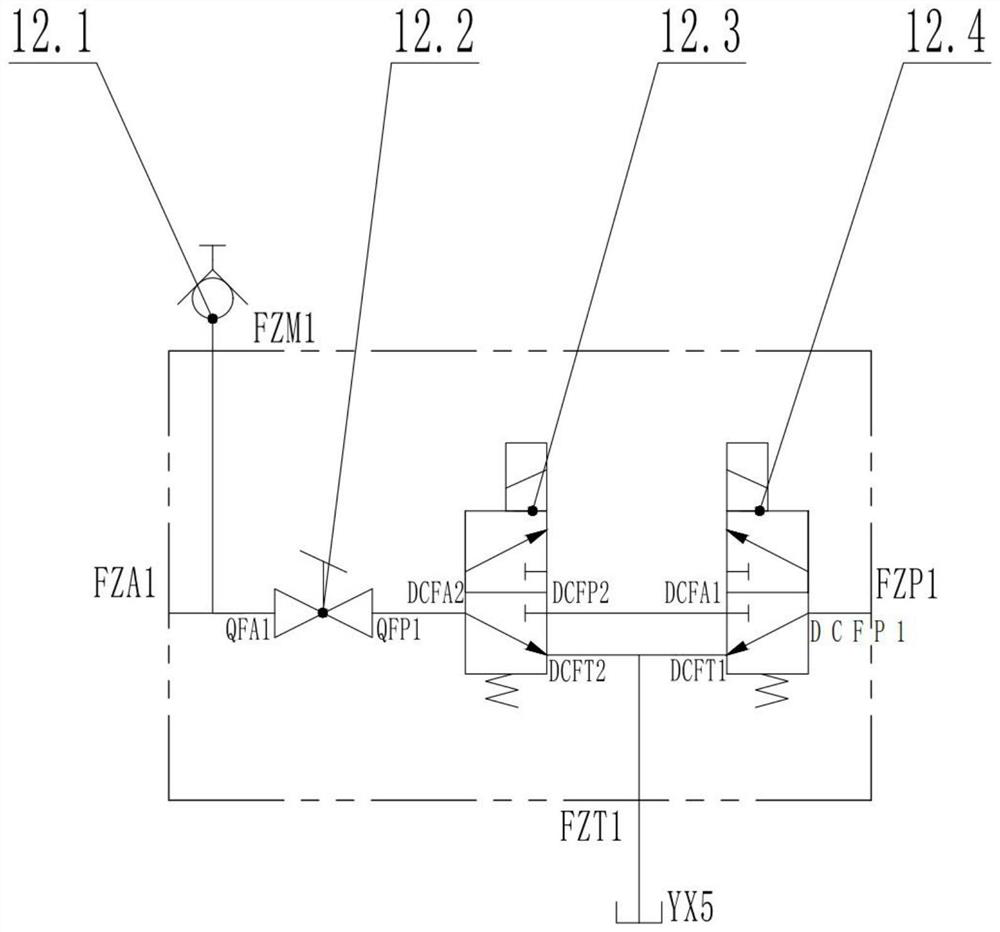

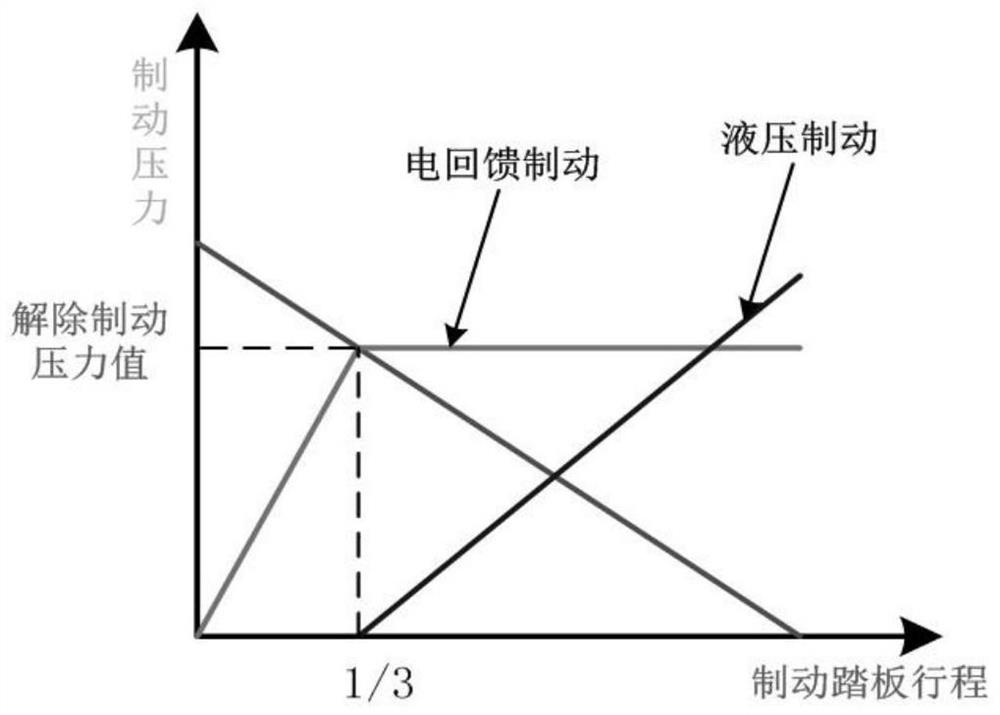

[0038] Such as Figure 1-3 As shown, this embodiment provides a negative motor hydraulic combined braking control system for a two-way driving electric forklift, specifically a load sensing type motor hydraulic combined braking control system for a two-way driving electric forklift. The system includes hydraulic oil tank 1, oil suction filter 2, variable pump 3, pressure gauge Ⅰ 4, safety valve group 5, high pressure filter 6, oil pump motor 7, load sensing accumulator filling valve 8, brake valve Ⅰ 9, Check valve group 10, brake valve II 11, parking brake valve group 12, pressure measuring joint 12.1, high pressure ball valve 12.2, electromagnetic reversing valve I 12.3, electromagnetic reversing valve II 12.4, relay valve 13, pressure Table II14, accumulator 15, lead-acid battery 16, motor controller Ⅰ17, wheel side motor Ⅰ18, deceleration brake Ⅰ19, deceleration brake Ⅲ20, wheel side motor Ⅲ21, motor controller Ⅲ22, motor controller Ⅳ23, wheel side motor Ⅳ24 , deceleration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com