Low-viscosity silane modified polyether resin and preparation method thereof

A silane-modified polyether, low-viscosity technology, applied in the direction of polyether adhesives, adhesives, adhesive types, etc., can solve the problems of high resin viscosity, toxicity, and low modulus, and achieve simple steps, Easy to operate, good elastic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

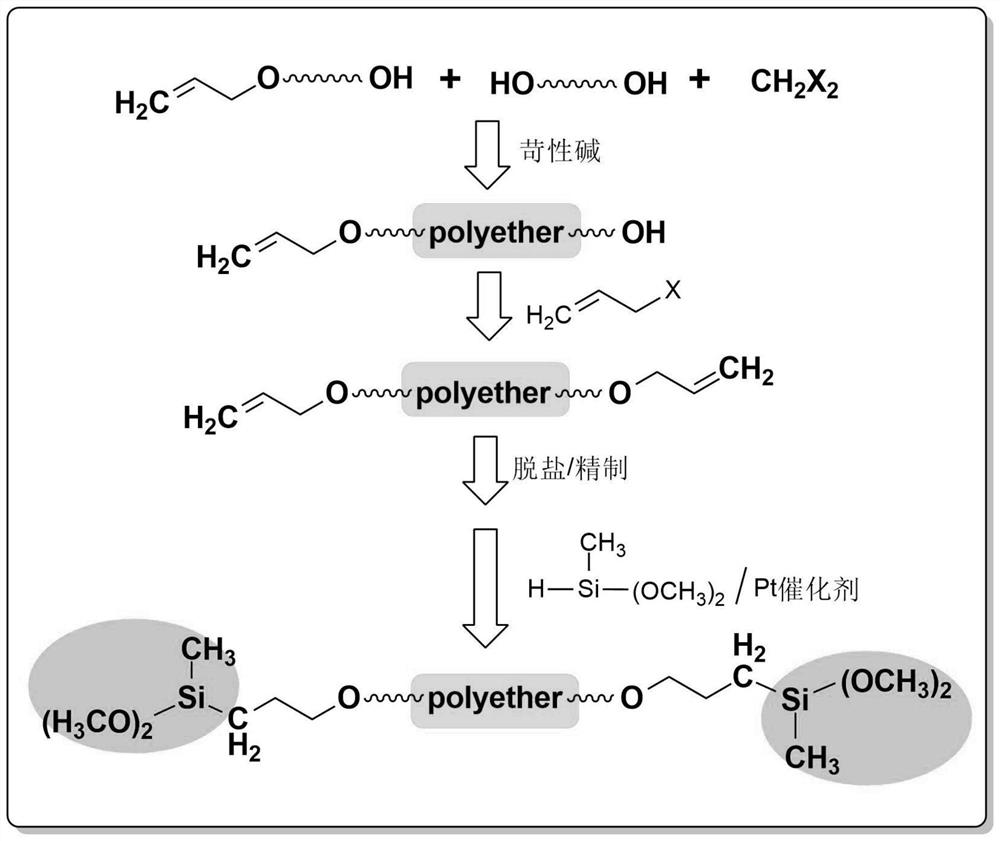

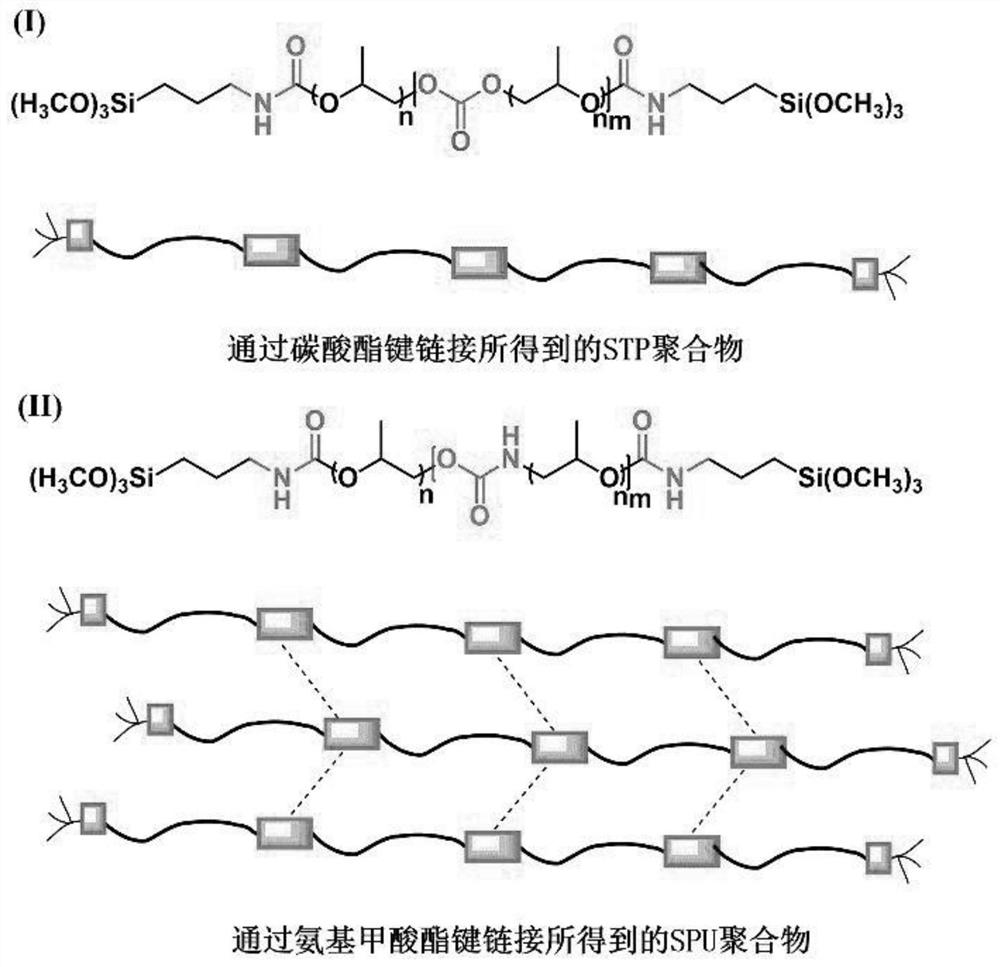

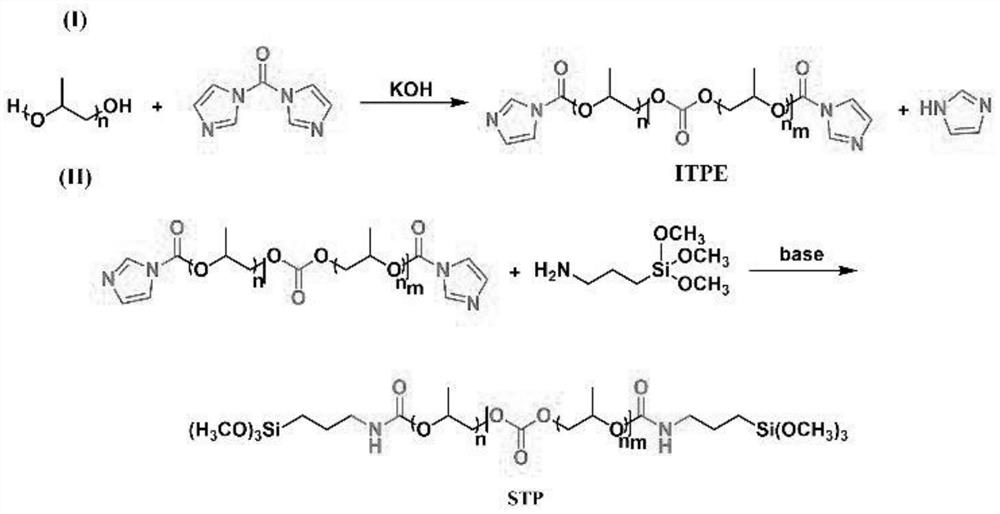

Method used

Image

Examples

Embodiment 1

[0055] A low-viscosity silane-modified polyether resin according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0056]

[0057]

[0058] The molecular weight of the polyether polyol is 8000 g / mol.

[0059] The base catalyst is KOH.

[0060] The weight ratio of N'N-carbonyldiimidazole to polyether polyol is 1.2:1.

[0061] The polyether polyol is polypropylene glycol; the aminosilane coupling agent is 3-aminopropyltrimethoxysilane.

[0062] The preparation method of described low-viscosity silane-modified polyether resin mainly comprises the following steps carried out in sequence:

[0063] (1) Take polyether polyol and remove water under vacuum for 2 hours at 110°C, then cool down to 70°C;

[0064] (2) Mix N'N-carbonyldiimidazole and alkali catalyst with the polyether polyol obtained in step (1), then pass through nitrogen protection, and heat up to 90°C for 2 hours to obtain reactant...

Embodiment 2

[0074] A low-viscosity silane-modified polyether resin according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0075]

[0076] The molecular weight of the polyether polyol is 4000 g / mol.

[0077] The base catalyst is triethylamine.

[0078] The polyether polyol is polypropylene glycol; the aminosilane coupling agent is any combination of 3-aminopropylmethyldimethoxysilane and 3-aminopropylmethyldiethoxysilane.

[0079] The preparation method of described low-viscosity silane-modified polyether resin mainly comprises the following steps carried out in sequence:

[0080] (1) Take polyether polyol and remove water under vacuum for 2.5 hours at 100°C, then cool down to 65°C;

[0081] (2) Mix N'N-carbonyldiimidazole and alkali catalyst with the polyether polyol obtained in step (1), then pass through nitrogen protection, and raise the temperature to 85° C. for 3 hours to obtain reactant A;

...

Embodiment 3

[0092] A low-viscosity silane-modified polyether resin according to the present invention is mainly prepared from the following components according to the following ratios by weight and number:

[0093]

[0094] The molecular weight of the polyether polyol is 6000 g / mol.

[0095] The base catalyst is triethylamine.

[0096] The polyether polyol is polypropylene glycol; the aminosilane coupling agent is 3-aminopropyltriethoxysilane, N-2-aminoethyl-3-aminopropylmethyldiethoxysilane and Any combination of N-2-aminoethyl-3-aminopropylmethyldimethoxysilane.

[0097] The preparation method of described low-viscosity silane-modified polyether resin mainly comprises the following steps carried out in sequence:

[0098] (1) Take polyether polyol and remove water under vacuum for 3 hours at 120°C, then cool down to 75°C;

[0099] (2) Mix N'N-carbonyldiimidazole and alkali catalyst with the polyether polyol obtained in step (1), then pass through nitrogen protection, and heat up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com