Preparation method of aluminum hydroxide surface modified expansible graphite flame retardant and method for preparing flame-retardant polyurethane foam plastic by using the same

A technology of aluminum hydroxide and expanded graphite, applied in the field of flame retardant materials, can solve problems such as poor mechanical properties, achieve good flame retardant effect, save costs, and improve mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

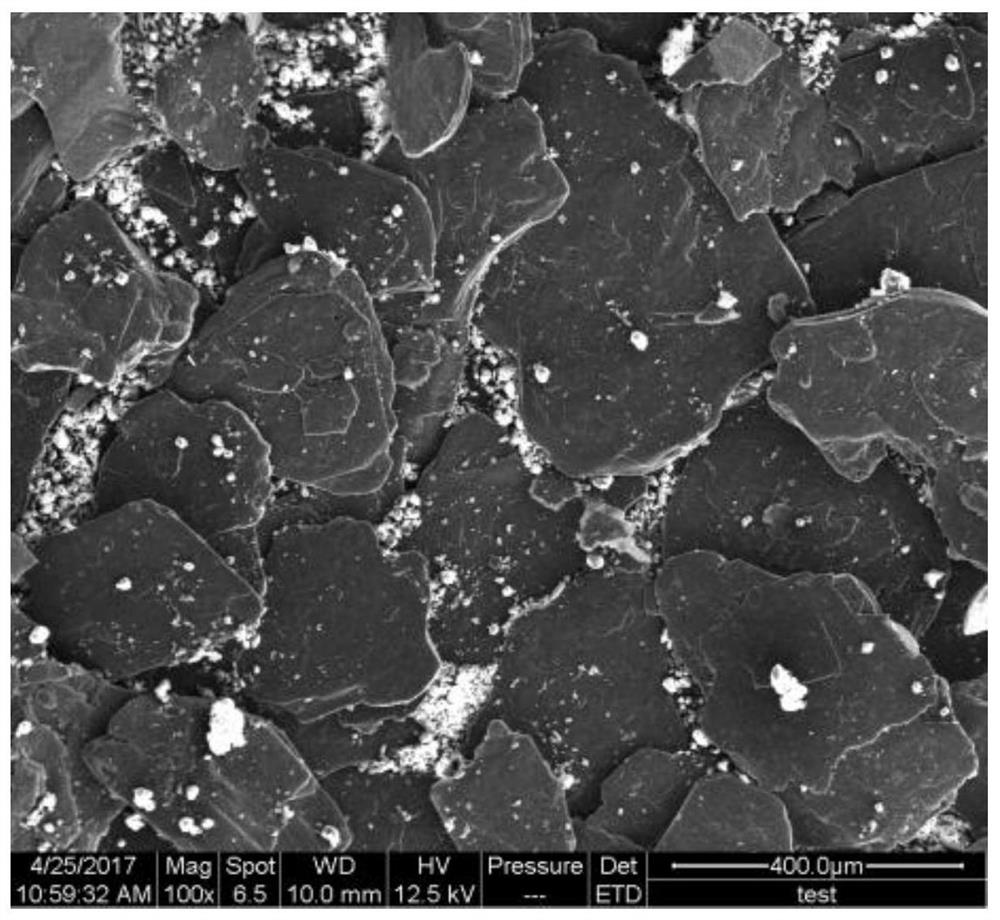

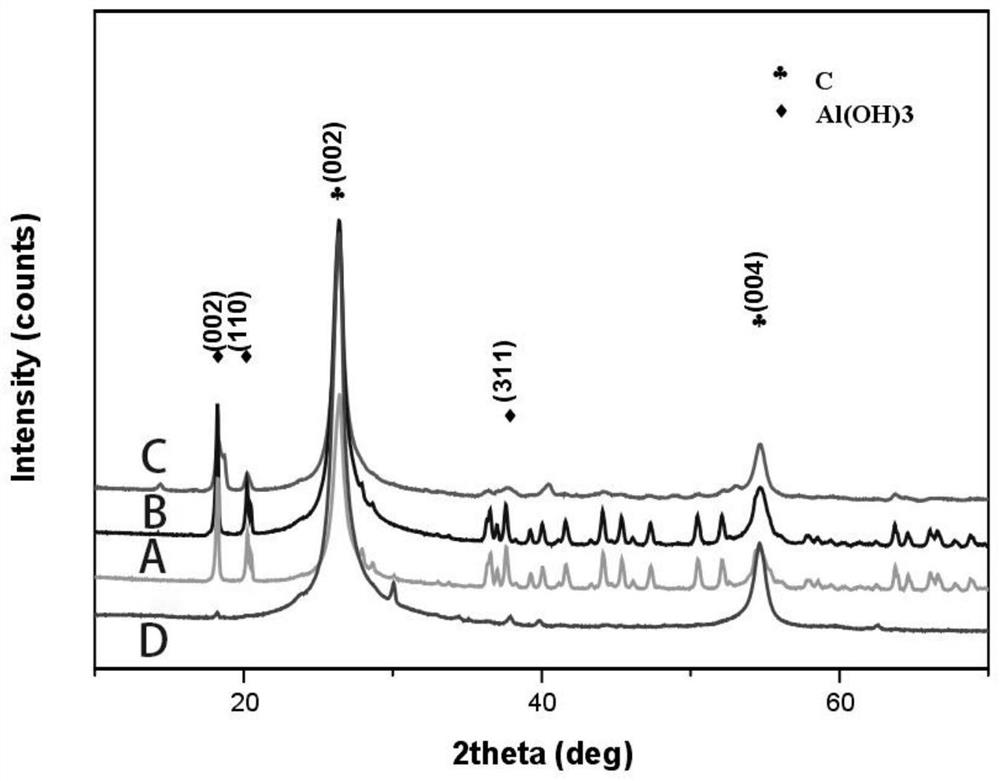

[0020] Specific Embodiment 1: This embodiment is a preparation method of an expandable graphite flame retardant modified on the surface of aluminum hydroxide, which is specifically completed in the following steps: using sodium hydroxide, aluminum hydroxide and expandable graphite as raw materials, using Aluminum hydroxide surface-modified expandable graphite flame retardant prepared by hydrothermal method.

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass fraction of aluminum hydroxide in the aluminum hydroxide surface-modified expandable graphite flame retardant is 30% to 45%. Others are the same as the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the specific operation process of the hydrothermal method is as follows: put expandable graphite and aluminum hydroxide into the reaction kettle, and then add a mixture with a pH of 11 Sodium hydroxide solution, stir and mix, cover the reaction kettle, heat up to 200-220°C, and react at a temperature of 200-220°C for 1.5h-2.5h, then cool to room temperature, the obtained solid-liquid mixture, Filtration, washing and vacuum drying are carried out successively to obtain the expandable graphite flame retardant with aluminum hydroxide surface modification. Others are the same as those in Embodiment 1 or 2.

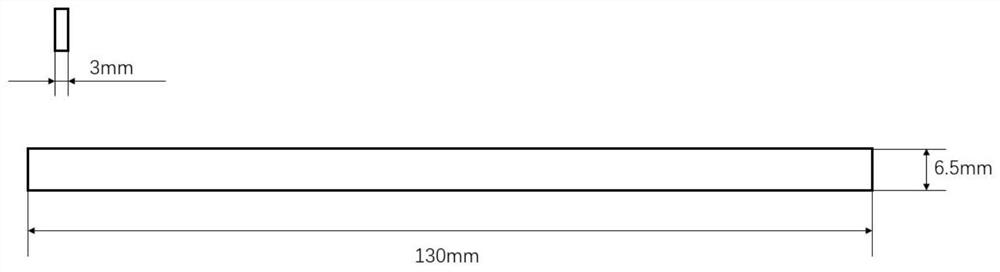

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com