Polypropylene capacitor film with high breakdown voltage

A high breakdown voltage, capacitor film technology, applied in the field of capacitor film, can solve the problems of difficulty in obtaining BOPP film, inability to meet oil immersion, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

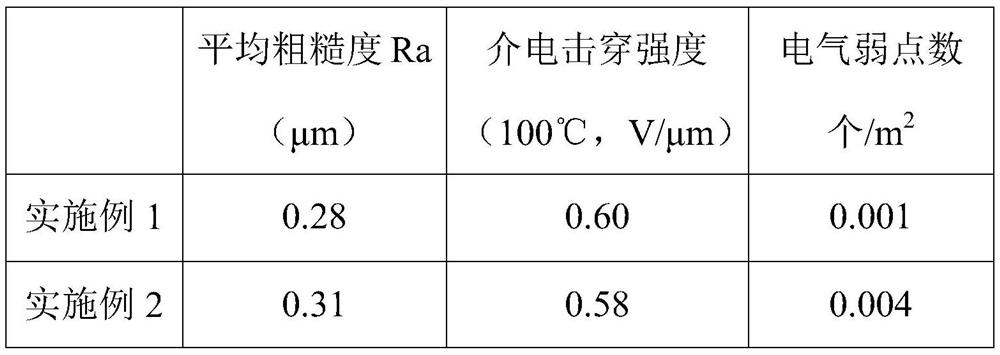

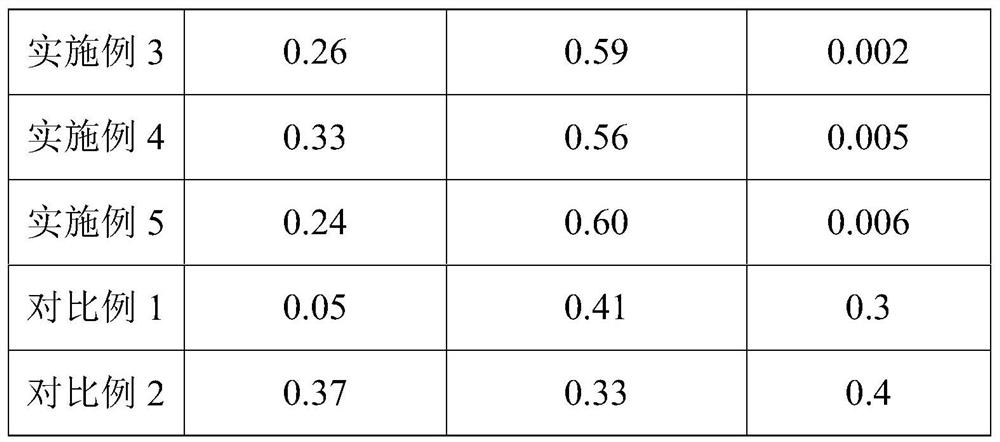

Examples

Embodiment 1

[0025] This embodiment proposes a polypropylene capacitor film with high breakdown voltage, which is prepared by the following method:

[0026] Heat polypropylene with an isotacticity of 98.5%, an ash content of 20ppm, and a melt index of 3.1g / 10min (according to GB / T3682-2000 standard test) to 140°C and keep it warm for 15min. After cooling to room temperature, pre-crystallization is obtained. Polypropylene; the β-nucleating agent (5,12-dihydro-quinolino[2,3-b]acridine-7,14-dione of the pre-crystallized polypropylene and polypropylene mass 0.1%) ) is added into a twin-screw extruder, and melted and extruded by the extruder, and the extrusion temperature is controlled at 250° C. to obtain a sheet-like melt;

[0027] The resulting flake melt is cooled by the cooling roll and the casting air knife. The temperature of the cooling roll is controlled at 100°C, and the gas temperature of the casting air knife is consistent with that of the cooling roll. The biaxial stretching equip...

Embodiment 2

[0029] This embodiment proposes a polypropylene capacitor film with high breakdown voltage, which is prepared by the following method:

[0030] Heat polypropylene with an isotacticity of 98.5%, an ash content of 20ppm, and a melt index of 3.1g / 10min (according to GB / T3682-2000 standard test) to 130°C and keep it warm for 20min. After cooling to room temperature, pre-crystallization is obtained. The polypropylene; the β-nucleating agent (5,12-dihydro-quinolino[2,3-b]acridine-7,14-dione of the pre-crystallized polypropylene and polypropylene mass 0.05%) ) is added into a twin-screw extruder, and melted and extruded by the extruder, and the extrusion temperature is controlled at 260° C. to obtain a sheet-like melt;

[0031] The obtained flake melt is cooled by the cooling roll and the casting air knife. The temperature of the cooling roll is controlled at 105°C, and the gas temperature of the casting air knife is consistent with that of the cooling roll. The biaxial stretching e...

Embodiment 3

[0033] This embodiment proposes a polypropylene capacitor film with high breakdown voltage, which is prepared by the following method:

[0034] Heat polypropylene with an isotacticity of 98.5%, an ash content of 20ppm, and a melt index of 3.1g / 10min (according to GB / T3682-2000 standard test) to 150°C and keep it warm for 5min. After cooling to room temperature, pre-crystallization is obtained. Polypropylene; the β-nucleating agent (5,12-dihydro-quinolino[2,3-b]acridine-7,14-dione of the pre-crystallized polypropylene and polypropylene mass 1%) ) into a twin-screw extruder, melted and extruded using the extruder, and the extrusion temperature is controlled at 240°C to obtain a sheet-like melt;

[0035] The resulting flake melt is cooled by the cooling roll and the casting air knife. The temperature of the cooling roll is controlled at 100°C, and the gas temperature of the casting air knife is consistent with that of the cooling roll. The biaxial stretching equipment carries ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap