Steering structure for molten metal quenching

A technology of molten metal and quenching pool, applied in the direction of quenching device, furnace type, furnace, etc., can solve the problems of unstable furnace atmosphere, unstable product quality, increased production costs, etc., to maintain the furnace atmosphere, ensure product quality stability, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

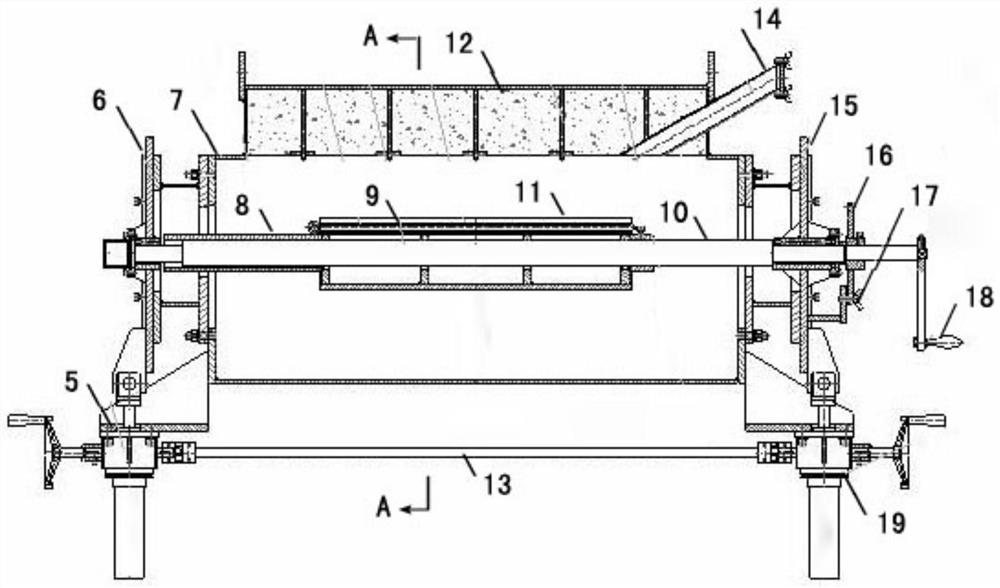

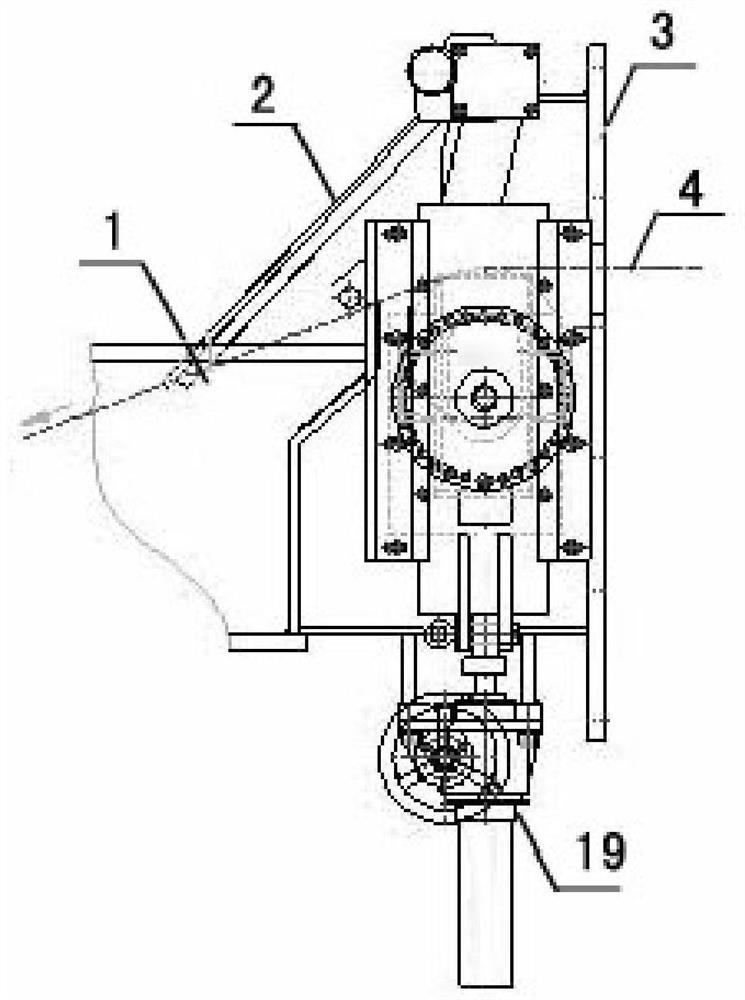

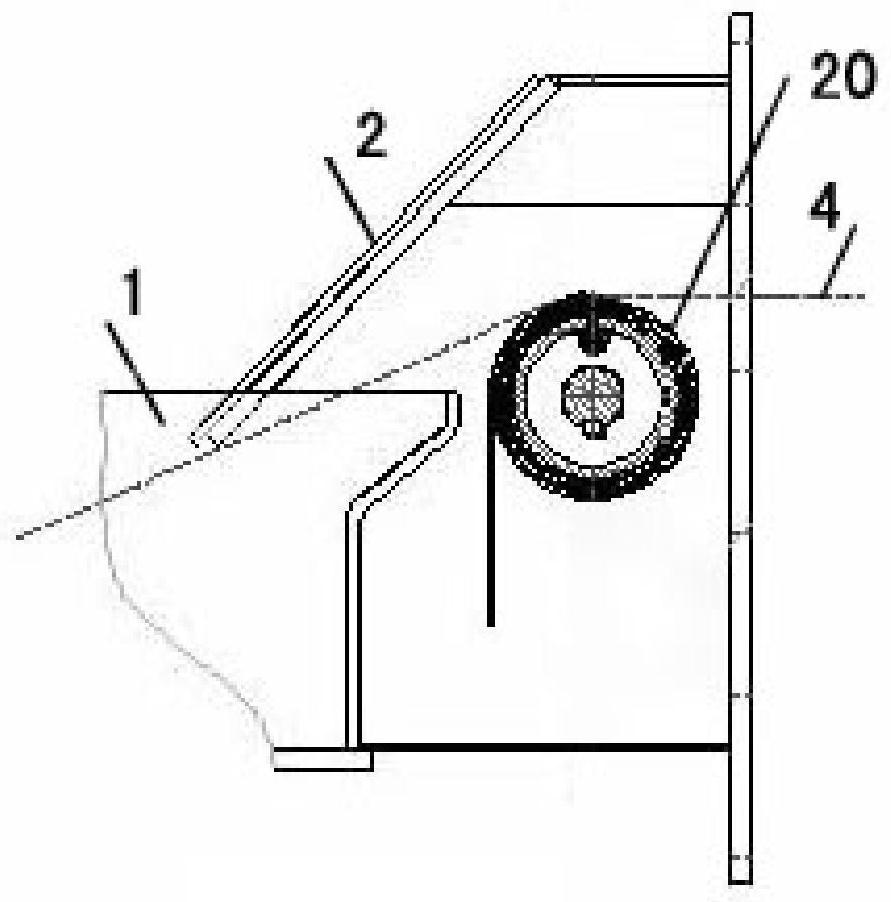

[0024] refer to figure 1 , figure 2 and image 3 The specific embodiment 1 of the present invention is arranged at the entrance of the molten metal quenching pool 1, including a box body 7, a rotating shaft mechanism and a lifting mechanism. 7, the end of the rotating shaft 10 is located outside the box 7 and is connected with a rotating drive structure 18; the reel 11 is wound with a wear-resistant cloth 20, and the wear-resistant cloth 20 is wound on the drum 11 An extensible roll structure is formed to facilitate the replacement of the wear-resistant cloth on the rotating line by driving the rotating shaft 10; the lifting mechanism is connected to the bottom surface of the rotating shaft mechanism to form a driving structure for the rotating shaft mechanism to rise or fall.

[0025] In this example:

[0026] Described rotating shaft mechanism comprises rotating shaft 10 and left bearing seat 6, right bearing seat 15, and left bearing seat 6, right bearing seat 15 are ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com