A thin-walled square tube continuous restraint quenching device

A quenching device and thin-walled technology, which is applied in the direction of quenching devices, furnaces, heat treatment equipment, etc., can solve the problems of poor controllability, low production efficiency, and poor uniformity of the quenching process, and achieve improved mechanical properties and service performance, and high production efficiency , High-strength uniform quenching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

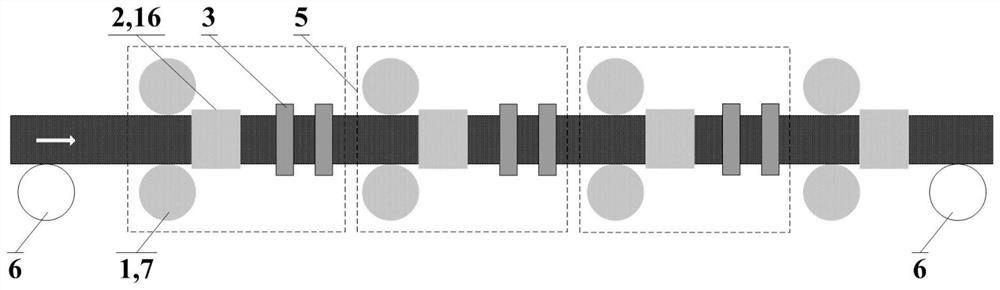

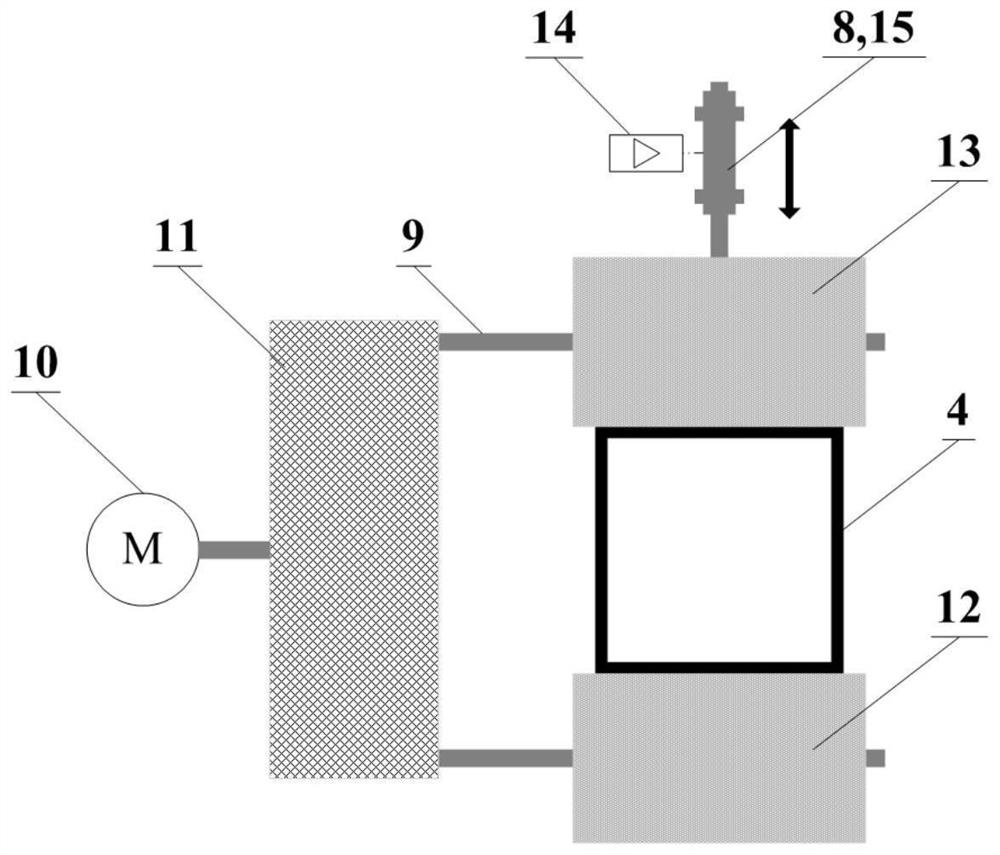

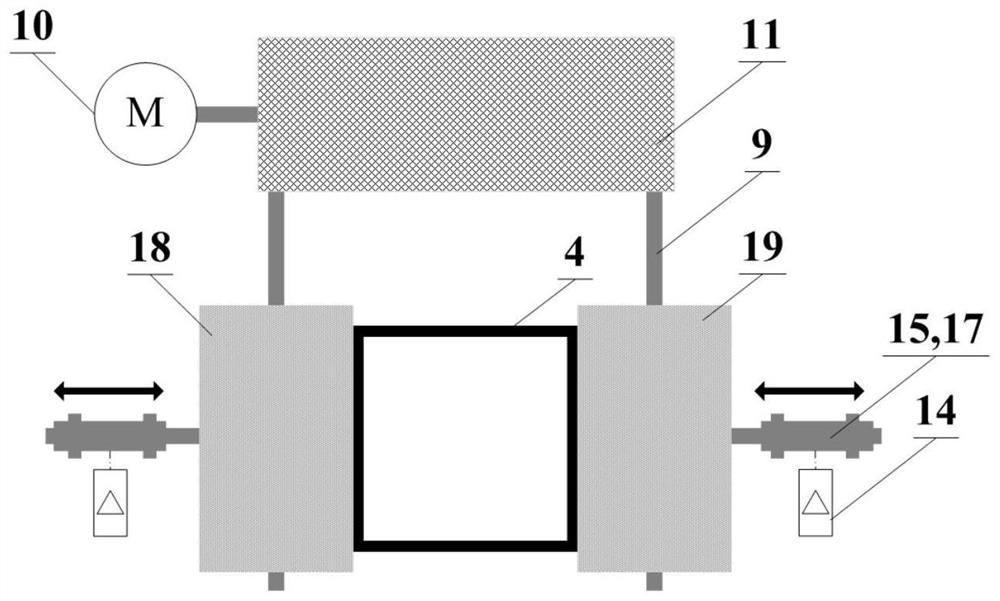

[0023] Take the wear-resistant steel square tube with an outer side length of 150mm and a wall thickness of 8mm as an example. Figure 1-5 , to explain the specific implementation of the thin-walled square tube continuous restraint quenching device. Before the square tube 4 is quenched, the hydraulic cylinder 15 installed on the side of the traverse mechanism 22 of the water spray system 3 is controlled and extended by the servo control system 14, the large water spray unit 20 is positioned on the concentric axis of the square tube 4, and the small water spray unit 21 is positioned. Move laterally out of the quenched area. From front to back, a total of 5 groups of water spray systems and 3 large water spray units 20 are opened, with a pressure of 2bar and a water volume of 40m 3 The cooling water per hour enters the 4 groups of water mist nozzles 25 of the 3 large water spray units 20 of the water spray system through the water inlet pipeline 24, with a pressure of 4 bar and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com