Manufacturing process and manufacturing equipment of environment-friendly corrugated carton

A corrugated box, green and environmentally friendly technology, which is applied in box making operations, rigid/semi-rigid container manufacturing, paper, etc., can solve the problems of corrugated box environmental protection performance to be improved, to avoid stacking deformation, speed up degradation efficiency, and avoid development The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

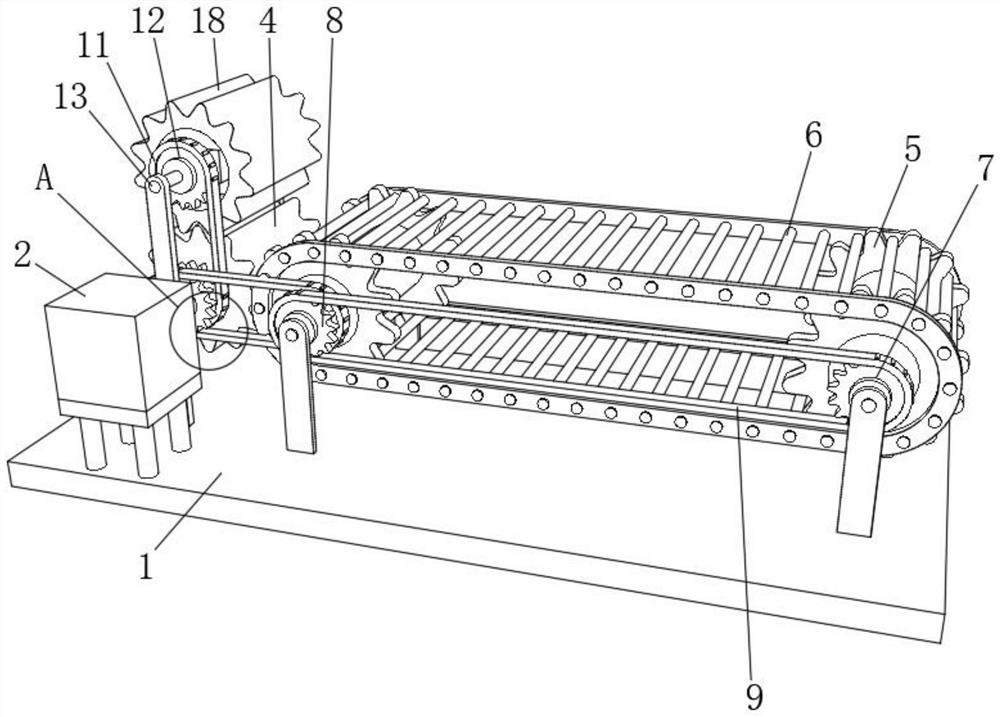

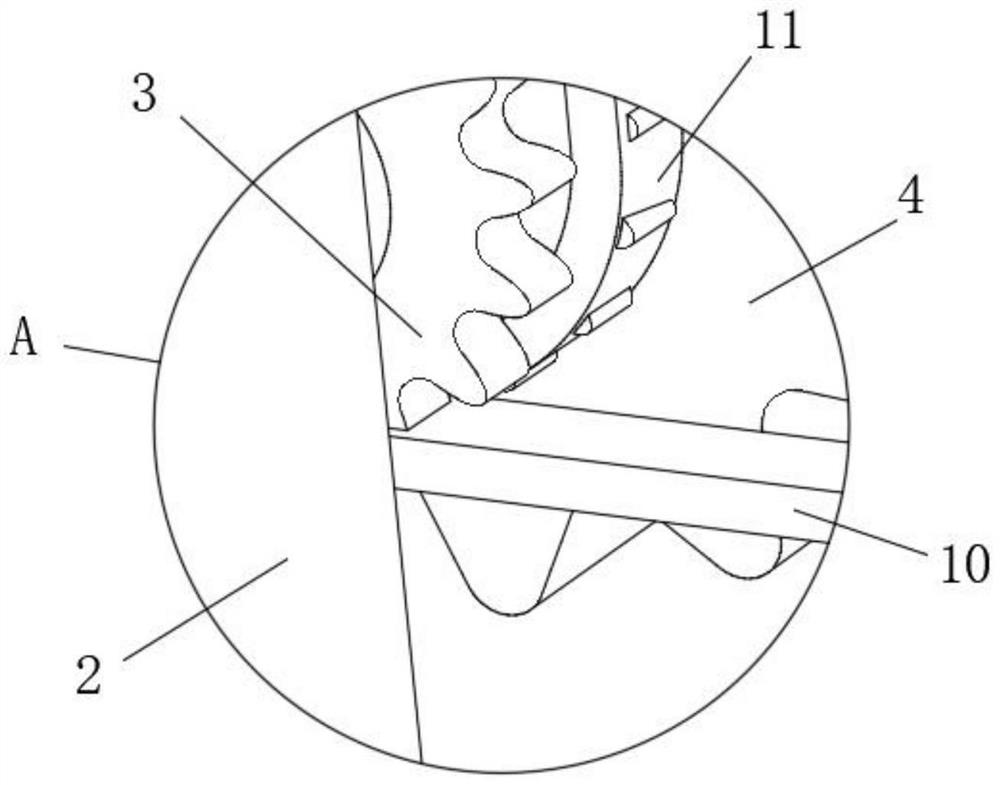

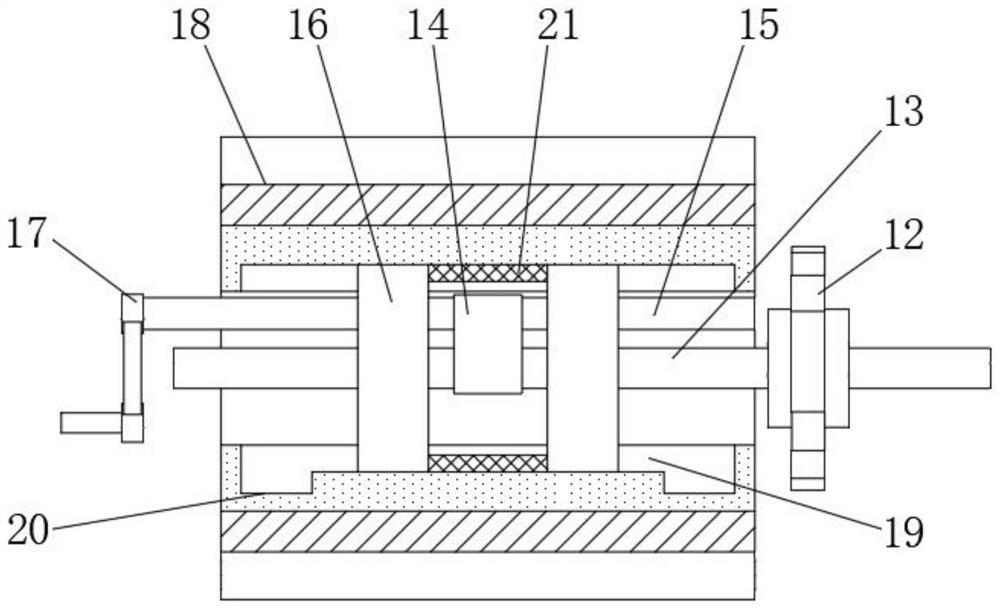

[0032] Such as Figure 1-4 As shown, the embodiment of the present invention provides a green environment-friendly corrugated box manufacturing process and its manufacturing equipment, including a base 1 and a hollow corrugated paper roller 18, the top of the base 1 is fixedly connected to a motor 2, and the output end of the motor 2 is fixedly connected to a double The front end of row sprocket A3 and double row sprocket A3 are fixedly connected with solid corrugated paper roller 4, and the right side of solid corrugated paper roller 4 is provided with two guide rollers 5, and both guide rollers 5 are meshed with chain A6, and the right side of chain A6 is The front end of the guide knuckle 5 is fixedly connected with a single sprocket A7, and the front end of the guide kun 5 on the left side of the chain A6 is fixedly connected with a double row sprocket B8, and the outside of the single row sprocket A7 and the front outside of the double row sprocket B8 are connected The ch...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap