Solid-waste-based fabricated thermal insulation wall and construction method thereof

A kind of thermal insulation wall, prefabricated technology, applied in thermal insulation, wall, manufacturing tools and other directions, to achieve the effect of promoting resource utilization, high construction efficiency, and achieving the same life expectancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

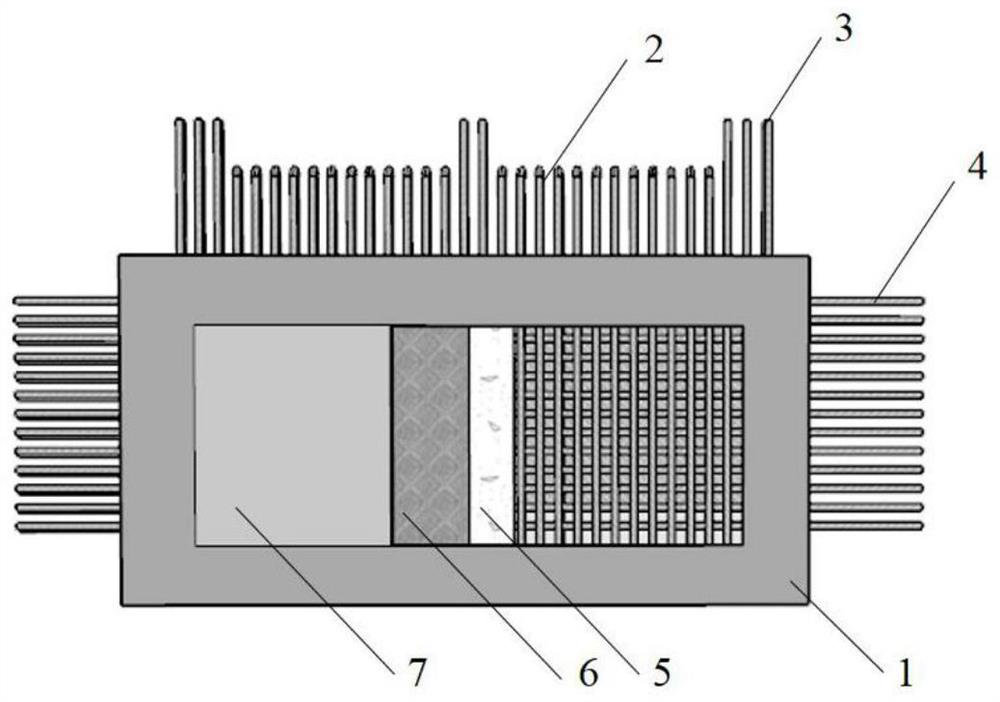

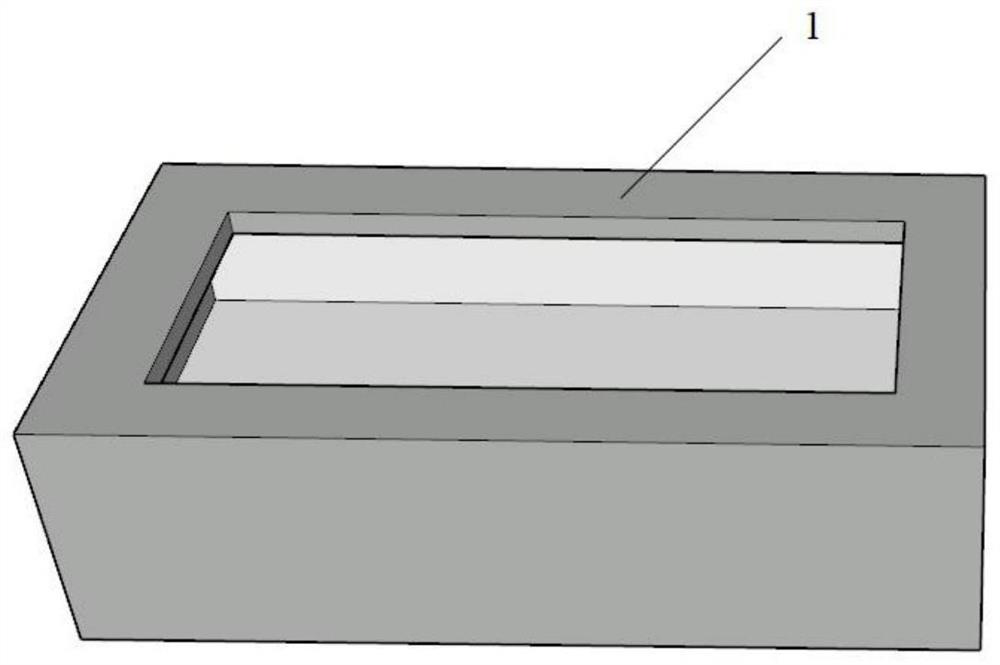

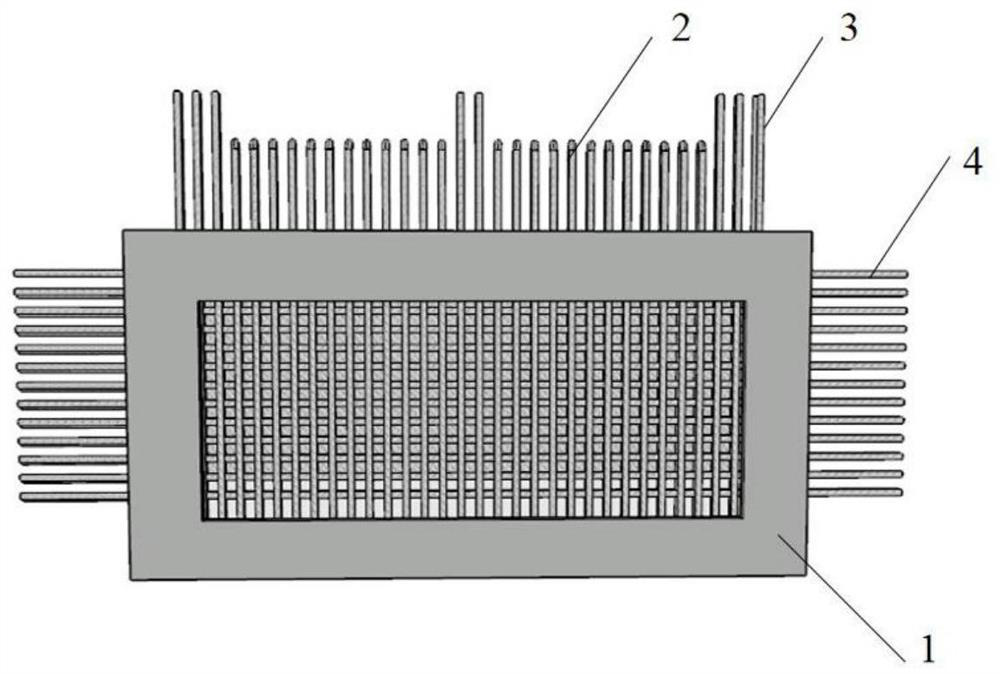

[0045] Specific implementation mode one: see Figure 1-6 This embodiment will be described. The solid waste-based assembled thermal insulation wall described in this embodiment includes a high-ductility solid waste-based cubic opening-free template 1 and a composite thermal insulation wall. The high-ductility solid waste-based cubic opening-free template 1 is wrapped in a composite thermal insulation wall. The outer periphery of the wall; the interior of the composite thermal insulation wall from bottom to top (construction sequence) is a reinforced concrete layer, an insulation layer 6 and a self-leveling mortar layer 7; For building exterior.

[0046] The mix ratio of the high-ductility solid waste-based cubic opening-free formwork 1 is: cement 252.8kg / m 3 , fly ash 884.8kg / m 3 , solid waste glass powder 126.4kg / m 3 (300 mesh), quartz sand 455kg / m 3 , water 303kg / m 3 , fiber 26kg / m 3 , water reducer 16.43kg / m 3 .

[0047] The tensile strain of the high-ductility sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com