Heat injection and yield increase method for coal bed gas based on hydrofracture multi-branch horizontal well

A technology for hydraulic fracturing and coalbed methane, which is used in earth-moving drilling, wellbore/well components, and production fluids, etc. It can solve the problems of inability to exchange heat inside the coal body and poor thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will further illustrate the present invention.

[0022] The present invention is in a conventional CBM Late Production horizontal lateral well, the case where the buck and drainage of hydraulic fracturing has been unable to meet production needs, can not be applied to improve production of coalbed methane.

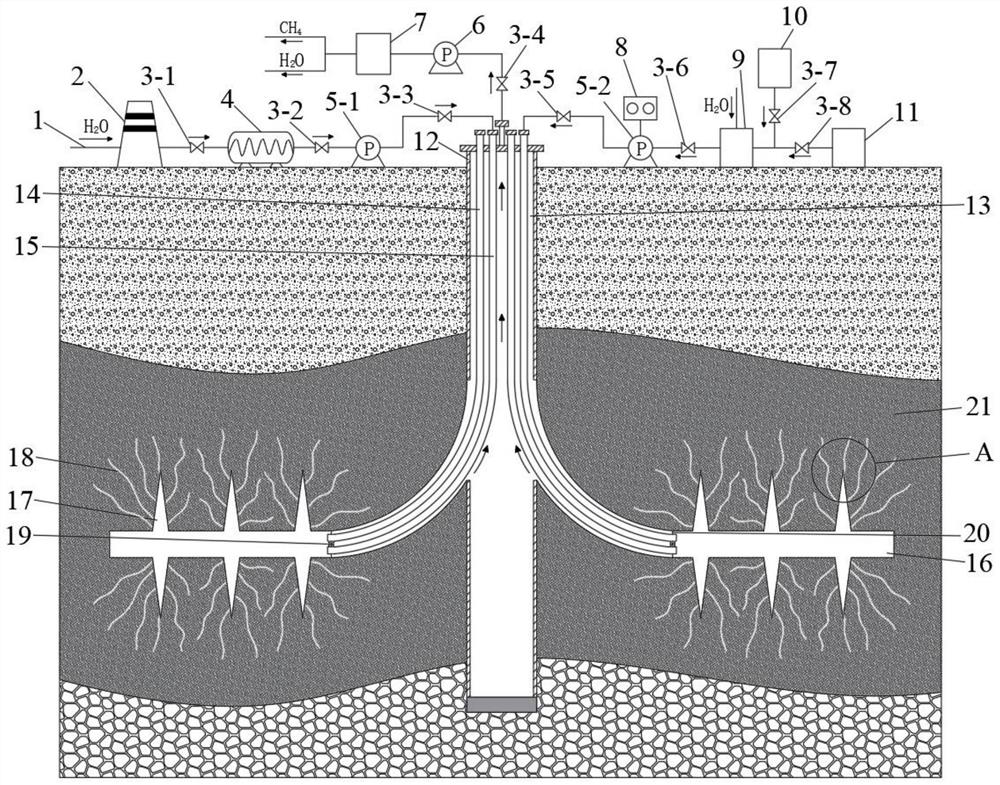

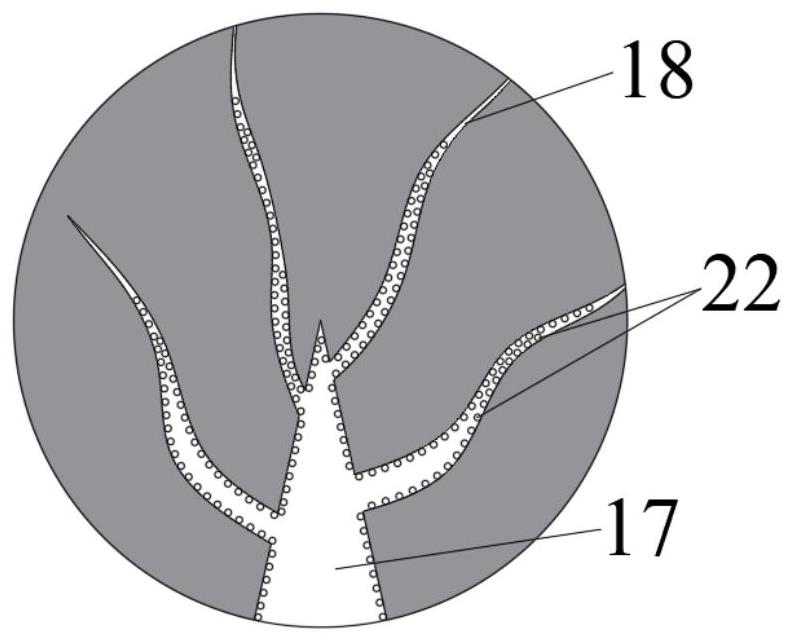

[0023] like figure 1 , The present embodiment is the specific steps:

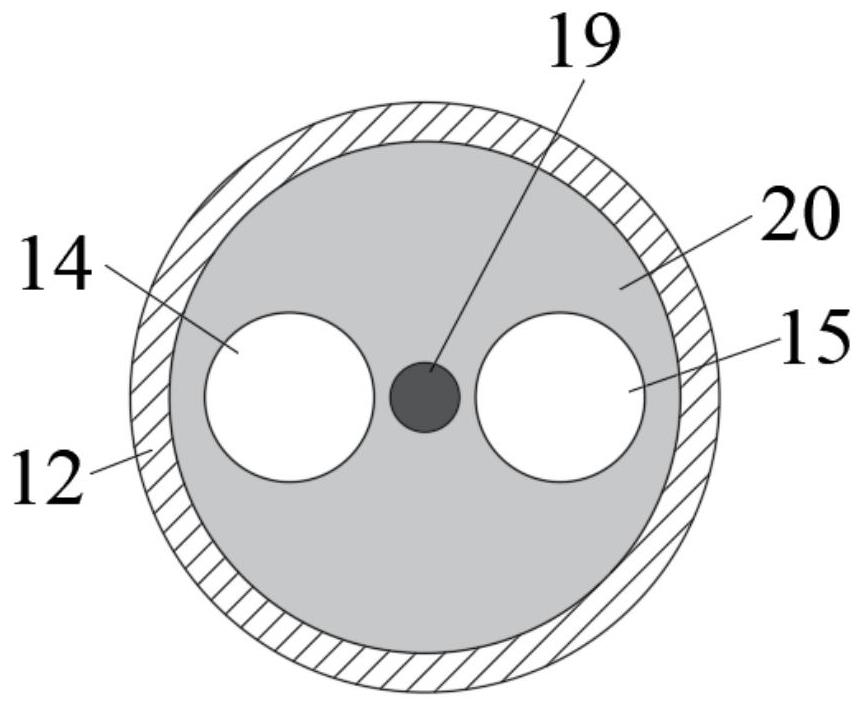

[0024] A, thermal stimulation assembly injection system: injection of the stimulation system comprises a steam generator heat station 2, the superheater 4, the first booster pump 5-1, 5-2 second booster pump, pressure pump 6, a gas separator 7, the pulsation pressure controller 8, the mixing chamber 9, nanoparticles storage tank 10, a surfactant tank 11, the packer 20, the steam injection pipe 14 and the injection tube 15, the outlet of the steam generator 2 via line station superheater 4 is connected to inlet, outlet superheater inlet line 4 is connected via a first booster pump 5-1, 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com