High-reflection high-barrier solar cell backboard film and preparation method thereof

A technology for solar cells and backplane films, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of easy local defects and poor consistency of solar cell backplane films, so as to achieve good overall performance consistency and not easy to local defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

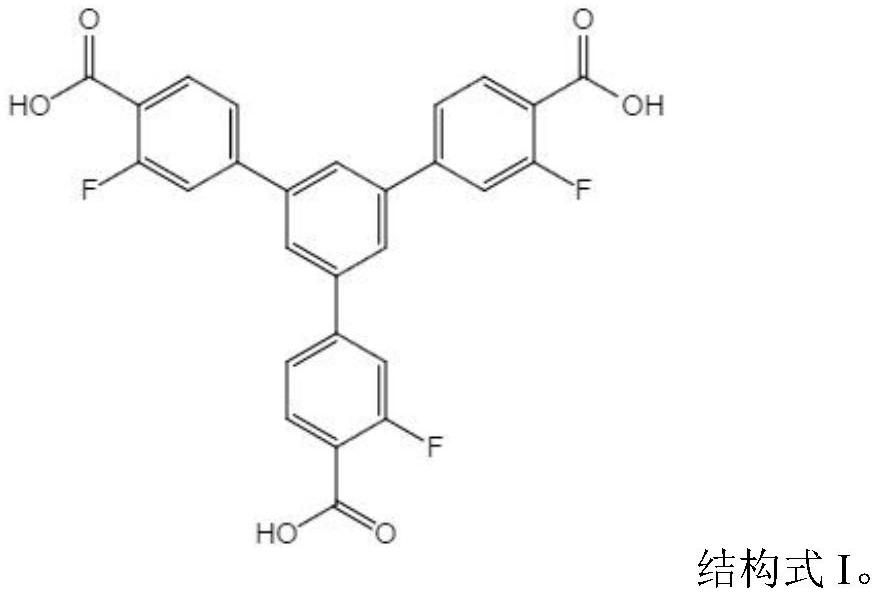

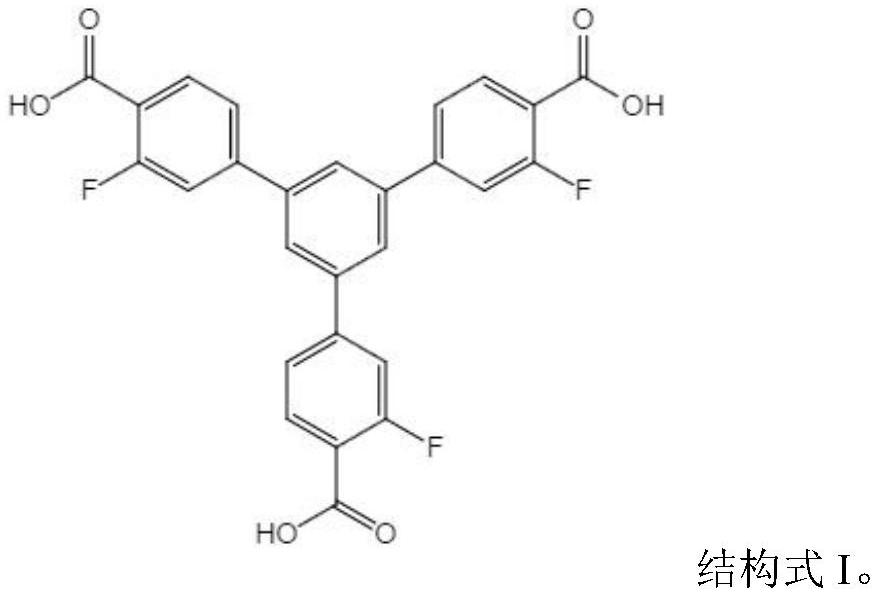

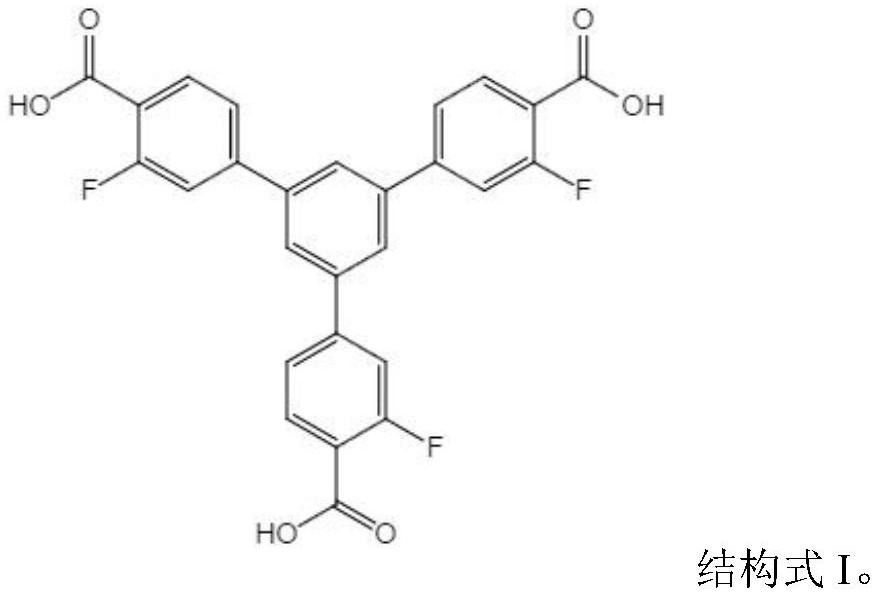

Image

Examples

Embodiment 1

[0024] The high-reflection and high-barrier solar cell backsheet film of this embodiment, the backsheet film includes an intermediate PET base film and a first coating and a second coating respectively arranged on the upper surface and the lower surface of the PET base film, so The first coating layer includes Ag-MOFs material coated titanium dioxide doped fluororesin, and the doping amount of the Ag-MOFs material coated titanium dioxide accounts for 30wt% of the mass ratio of the first coating layer. Described first coating also comprises additive, bisphenol A epoxy resin, acrylic resin; The mass ratio that described additive, bisphenol A epoxy resin and acrylic resin account for the first coating is 1.5wt%, 15wt% and 8wt%. The mass ratio of the fluororesin to the first coating is 45.5wt%. The fluororesin is polytetrafluoroethylene (PTFE). The additive is an ultraviolet absorber and a perfluorocage polysilsesquioxane with a mass ratio of 1:2. The ultraviolet absorber is UV...

Embodiment 2

[0035] The high-reflection and high-barrier solar cell backsheet film of this embodiment, the backsheet film includes an intermediate PET base film and a first coating and a second coating respectively arranged on the upper surface and the lower surface of the PET base film, so The first coating includes Ag-MOFs material coated with titanium dioxide doped fluororesin, and the doping amount of the Ag-MOFs material coated with titanium dioxide accounts for 35wt% of the mass ratio of the first coating. Described first coating also comprises additive, bisphenol A epoxy resin, acrylic resin; The mass ratio that described additive, bisphenol A epoxy resin and acrylic resin account for the first coating is 2.5wt%, 10wt% and 9 wt%. The mass ratio of the fluororesin to the first coating is 43.5wt%. The fluororesin is polyvinylidene fluoride (PVDF). The additive is an ultraviolet absorber and a perfluorocage polysilsesquioxane with a mass ratio of 1:2. The ultraviolet absorber is UV-...

Embodiment 3

[0046] The high-reflection and high-barrier solar cell backsheet film of this embodiment, the backsheet film includes an intermediate PET base film and a first coating and a second coating respectively arranged on the upper surface and the lower surface of the PET base film, so The first coating includes Ag-MOFs material coated with titanium dioxide doped fluororesin, and the doping amount of the Ag-MOFs material coated with titanium dioxide accounts for 40wt% of the mass ratio of the first coating. Described first coating also comprises additive, bisphenol A epoxy resin, acrylic resin; The mass ratio that described additive, bisphenol A epoxy resin and acrylic resin account for the first coating is 3.5wt%, 5wt% and 8wt%. The mass ratio of the fluororesin to the first coating is 43.5wt%. The fluororesin is polytetrafluoroethylene (PTFE). The additive is an ultraviolet absorber and a perfluorocage polysilsesquioxane with a mass ratio of 1:2. The ultraviolet absorber is UV-32...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com