Green stripping of waste lithium iron phosphate battery positive electrode material by using free radical system

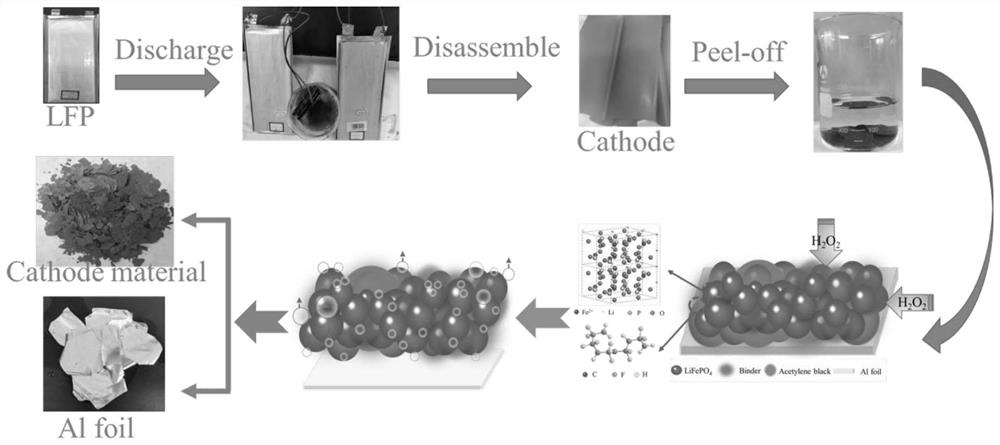

A lithium iron phosphate battery and cathode material technology, applied in battery recycling, secondary battery, recycling technology and other directions, can solve problems such as high price, high energy consumption, environmental pollution, etc., and achieve fast peeling speed, low material consumption, Simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

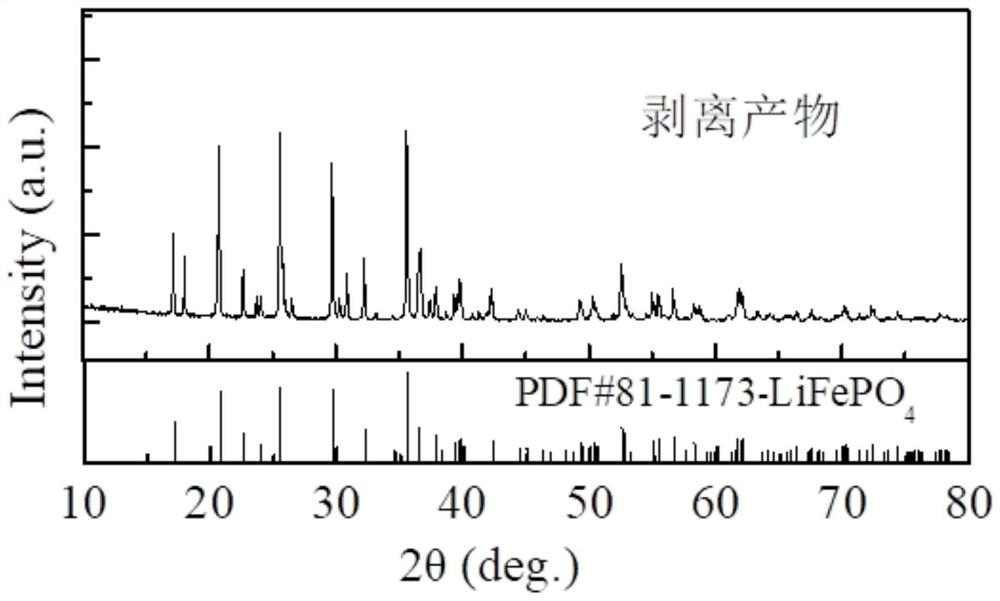

Method used

Image

Examples

Embodiment 1

[0024] Discharge and disassemble the waste lithium iron phosphate battery to obtain the positive pole piece, the negative pole piece, the casing and the separator respectively.

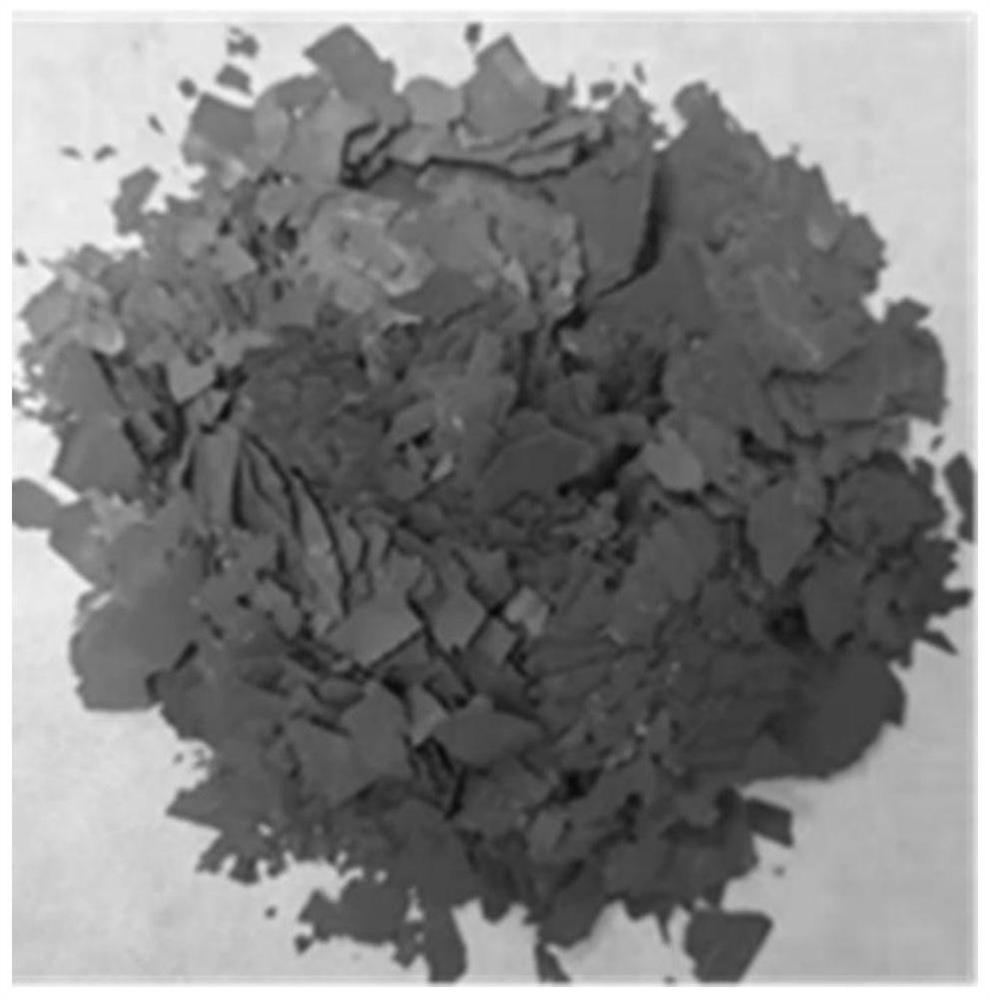

[0025] Cut the disassembled positive pole piece and put it into a stripping solution composed of 1% sodium peroxide and 0.25% ferrous chloride, stir at a speed of 600r / min for 10min, and the stripping efficiency reaches 100%. Then remove the aluminum foil and dry it, separate the stripping solution from solid and liquid, add the stripping solution to the filtrate and continue stripping, and the filter cake is the stripped lithium iron phosphate positive electrode material.

Embodiment 2

[0027] Discharge and disassemble the waste lithium iron phosphate battery to obtain positive pole pieces, negative pole pieces, shells, diaphragms, etc.

[0028] Cut the disassembled positive pole piece and put it into a stripping solution composed of 5% potassium persulfate and 0.25% ferrous sulfate, stir at a speed of 100r / min for 20min, and the stripping efficiency reaches 100%. Then remove the aluminum foil and dry it, separate the stripping solution from solid and liquid, add the stripping solution to the filtrate and continue stripping, and the filter cake is the stripped lithium iron phosphate positive electrode material.

Embodiment 3

[0030] Discharge and disassemble the waste lithium iron phosphate battery to obtain positive pole pieces, negative pole pieces, shells, diaphragms, etc.

[0031] After the positive electrode sheet obtained by splitting is cut, put into the stripping solution composed of 0.5% potassium persulfate, 3% sodium persulfate, and 1% ferrous sulfate, stir for 20min at a speed of 300r / min, and the stripping efficiency up to 100%. Then remove the aluminum foil and dry it, separate the stripping solution from solid and liquid, add the stripping solution to the filtrate and continue stripping, and the filter cake is the stripped lithium iron phosphate positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com