Preparation method of high-efficiency and environment-friendly graphene-paraffin phase change microcapsule material

A phase-change microcapsule and environmentally friendly technology, which is applied in the direction of microcapsule preparation, microsphere preparation, heat exchange materials, etc., can solve the problems of low production efficiency, high pollution, low yield, etc., and achieve low product loss and high yield High, low workload effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] Specific embodiment one: the preparation method of a kind of highly efficient and environment-friendly graphene-paraffin phase change microcapsule material of this embodiment, it is carried out according to the following steps:

[0039] 1. Dilute the concentration of graphene oxide in the brown-black graphene oxide thick slurry, and ultrasonically disperse the agglomerated graphene oxide completely to obtain a graphene oxide dispersion;

[0040] 2. Under the condition of a water bath with a temperature of 70° C. to 90° C., adjust the pH of the graphene oxide dispersion to 9 to 10 to obtain a pH-adjusted solution;

[0041] 3. Under the condition of a water bath with a temperature of 70°C-90°C, add solid paraffin to the pH-adjusted solution, heat until the solid paraffin melts, and use a three-blade stirring paddle at a temperature of 70°C-90°C and a speed of 900r Under the condition of / min~1300r / min, stir at a high speed for 0.5h~1.5h to obtain a brown dispersion liquid...

specific Embodiment approach 2

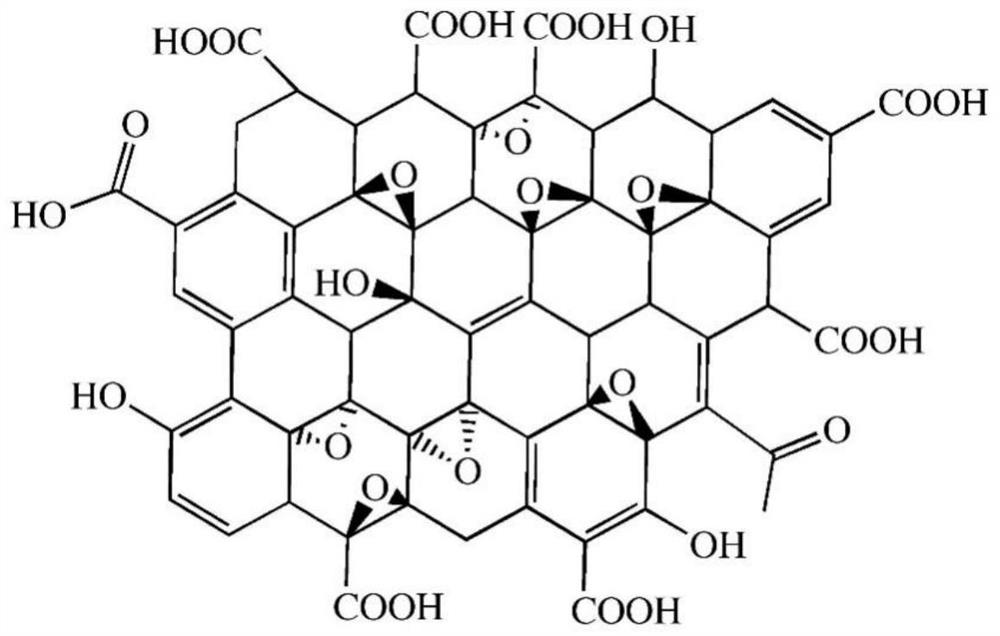

[0061] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the brown-black graphene oxide thick slurry described in step one is specifically prepared according to the following steps:

[0062] Mix flake graphite and concentrated sulfuric acid to obtain a mixture. Under the conditions of an ice bath and a stirring speed of 300rpm-600rpm, add potassium permanganate to the mixture within 30min and stir for 2h-4h to obtain a purple-black viscous liquid. Under the condition of water bath and stirring speed of 300rpm-600rpm, the temperature of purple-black viscous liquid is raised to 30°C-50°C, and the temperature is 30°C-50°C, and heated for 15min-60min to obtain purple-black viscous liquid For slurry, under the conditions of water bath and stirring speed of 300rpm-600rpm, first raise the temperature of the purple-black viscous slurry to 45°C-55°C and add deionized water A, then raise the temperature to 65°C-75°C and add deionized water B ...

specific Embodiment approach 3

[0063] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass ratio of described flake graphite to the concentrated sulfuric acid is 1g:(15~30) mL; Described flake graphite and The mass ratio of potassium permanganate is 1:(5~8); the quality of described flake graphite and the volume ratio of deionized water A are 1g:(20~40) mL; the quality of described flake graphite and deionized water A The volume ratio of ionized water B is 1g:(30~60)mL; the volume ratio of the mass of described flake graphite to distilled water is 1g:(60~80)mL; the mass and mass percentage of described flake graphite is 3 The volume ratio of %-10% hydrogen peroxide is 1g:(30-60) mL; the mass percentage of the concentrated sulfuric acid is 98%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com