Catalyst as well as preparation method and application thereof

A catalyst and co-catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of incomplete catalytic oxidation of formaldehyde, poor stability, low oxidation activity, etc., and achieve inhibition of self-poisoning effect, Enhanced stability and large stacking voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

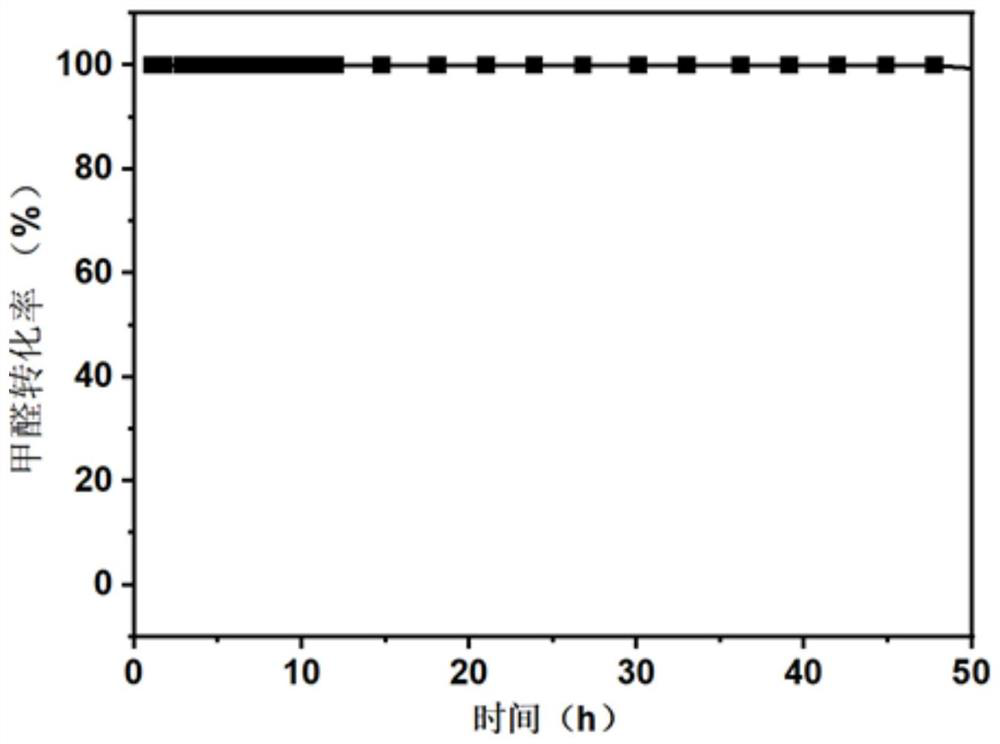

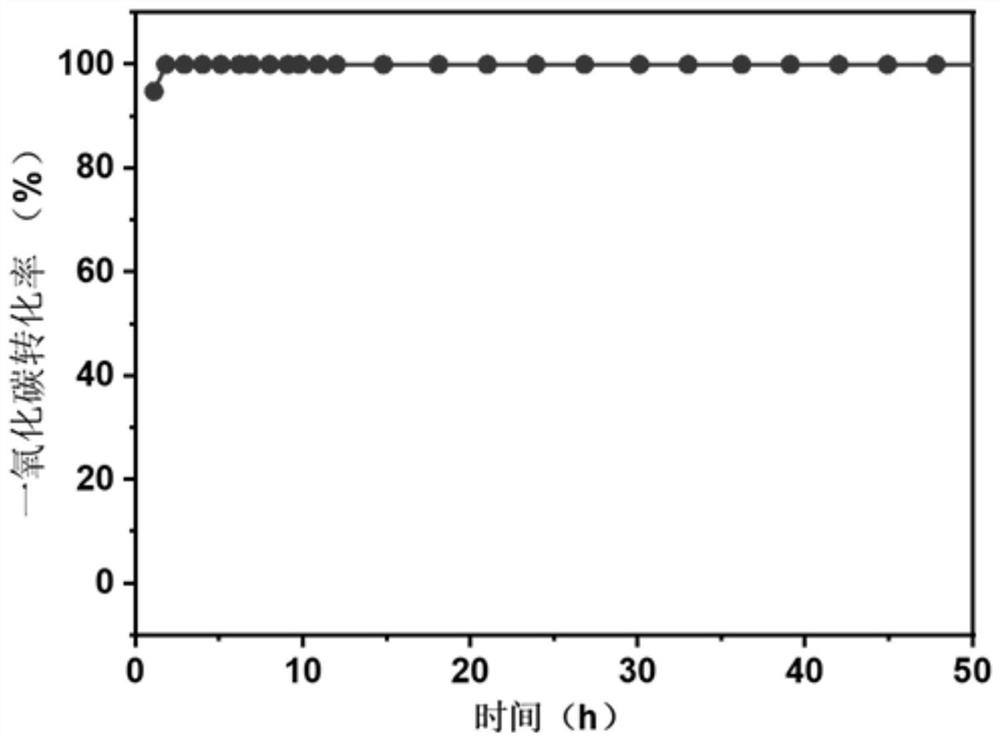

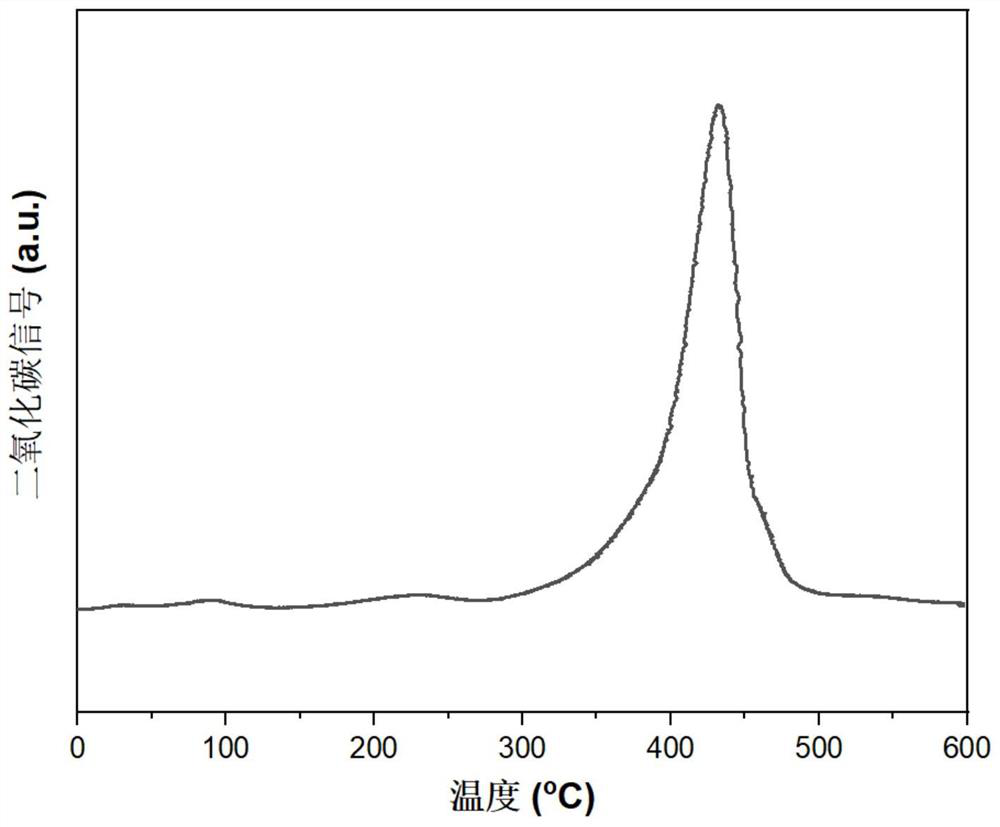

[0048] This embodiment provides a catalyst, which includes a spherical alumina carrier, cerium oxide supported on the alumina carrier, a platinum active component supported on the surface of the cerium oxide, and a carbon additive supported on the surface of the platinum active component;

[0049] Among them, the maximum major diameter of the alumina carrier is 4 mm, the mass ratio of cerium oxide to alumina carrier is 20:100, the mass ratio of platinum to alumina carrier is 0.2:100, and the mass ratio of carbon additive to alumina carrier is 0.02:100.

[0050] The preparation method of described catalyst is as follows:

[0051] (1) Load cerium nitrate on a 4mm long-diameter alumina support by impregnation method, dry at 80°C overnight and then bake at 450°C for 2h to obtain 20% CeO 2 / Al 2 o 3 , and then Pt was supported on CeO by the impregnation method 2 surface, dried overnight at 80°C, and then calcined at 450°C for 2 hours to obtain a catalyst precursor;

[0052] (2...

Embodiment 2

[0055] This embodiment provides a catalyst, which comprises a spherical alumina carrier, cerium oxide loaded on the alumina carrier, a palladium active component loaded on the surface of the cerium oxide, and a carbon additive loaded on the surface of the palladium active component;

[0056] Wherein, the maximum long diameter of alumina carrier is 10mm, the mass ratio of cerium oxide and alumina carrier is 30:100, the mass ratio of palladium and alumina carrier is 0.5:100, the mass ratio of carbon additive and alumina carrier is 0.05:100.

[0057] The preparation method of described catalyst is as follows:

[0058] (1) Load cerium nitrate on a 10mm-long-diameter alumina support by impregnation method, dry at 80°C overnight, and then bake at 450°C for 2 hours to obtain 30% CeO 2 / Al 2 o 3 , and then palladium was supported on CeO by the impregnation method 2 surface, dried overnight at 80°C, and then calcined at 450°C for 2 hours to obtain a catalyst precursor;

[0059] (2...

Embodiment 3

[0061] This embodiment provides a catalyst, which includes a spherical alumina carrier, cerium oxide supported on the alumina carrier, a platinum active component supported on the surface of the cerium oxide, and a carbon additive supported on the surface of the platinum active component;

[0062] Among them, the maximum long diameter of the alumina carrier is 4 mm, the mass ratio of cerium oxide to alumina carrier is 10:100, the mass ratio of platinum to alumina carrier is 0.8:100, and the mass ratio of carbon additive to alumina carrier is 0.005:100.

[0063] The preparation method of described catalyst is as follows:

[0064] (1) Load cerium nitrate on an alumina carrier with a long diameter of 4mm by impregnation method, dry at 80°C overnight and then bake at 450°C for 2h to obtain 10% CeO 2 / Al 2 o 3 , and then Pt was supported on CeO by the impregnation method 2 surface, dried overnight at 80°C, and then calcined at 450°C for 2 hours to obtain a catalyst precursor; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com