Concrete box type building module, modular building and construction method of modular building

A technology of reinforced concrete and concrete roof, applied in the direction of building structure, building, building components, etc., can solve the problems of high labor cost, high labor demand, harsh construction environment for workers, etc., and achieve the effect of simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

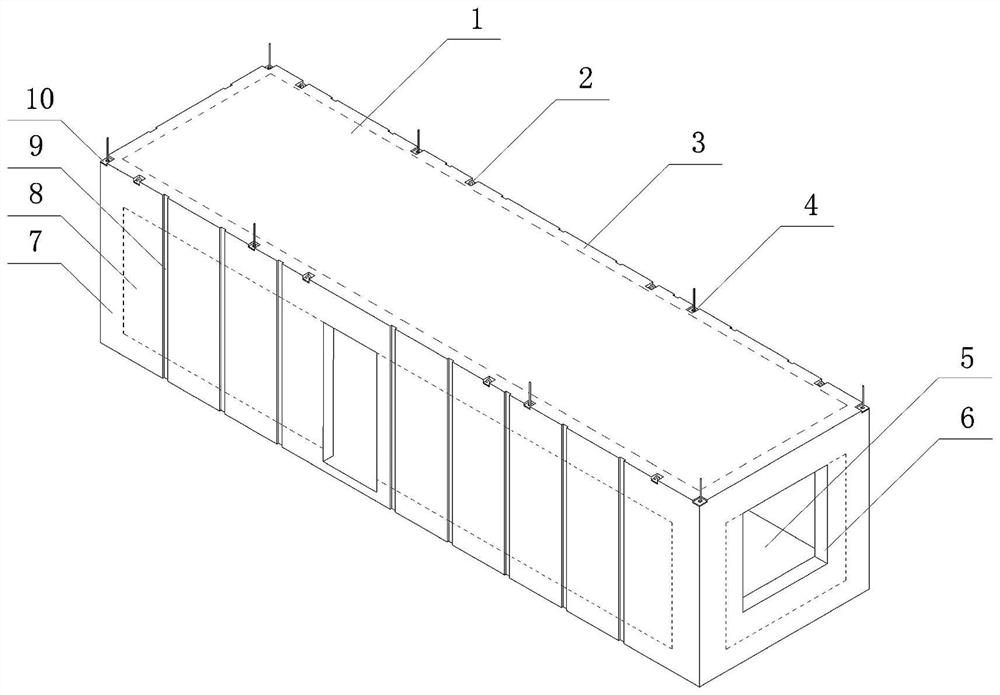

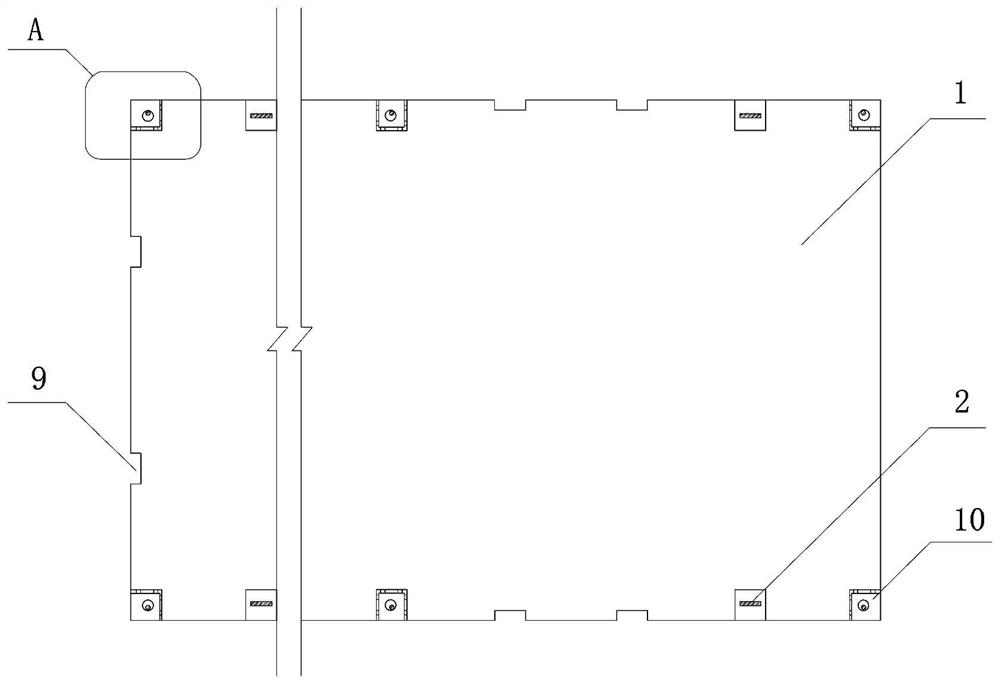

[0054] Such as figure 1 As shown, according to the design drawings, the reinforced concrete box-type building module unit with six faces formed by the top plate 1, the wall plate 8 and the bottom plate 5 is produced. It also includes a suspension ring 2, a through-type slurry anchor connection cavity 4, a transverse connection groove 10, a through-type engagement groove 9, and door and window openings 6.

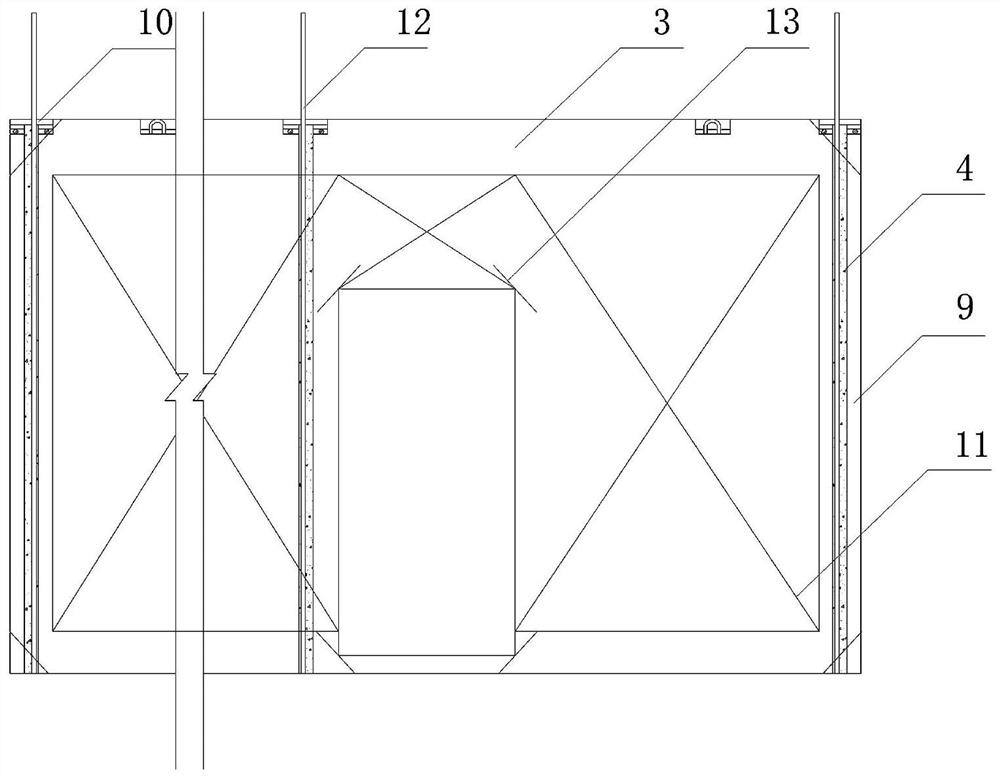

[0055] Such as figure 2 As shown, the criss-cross steel mesh is fixed on the inner mold of the box mold, the tie bars 11 and the reinforcing ribs 13 are installed, and the steel bars on each surface are connected as a whole to form a three-dimensional network frame. The mold of door, window hole 6 is installed. Fabrication ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com