Construction technology of tunnel penetrating through overlapping section of rockburst section and low-gas area

A construction technique and low-gas technology, applied in tunnels, tunnel linings, gas discharge, etc., can solve the problems of increased technology and management risks in tunnel construction, and achieve the effects of reducing secondary disasters, weakening fragility, and reducing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

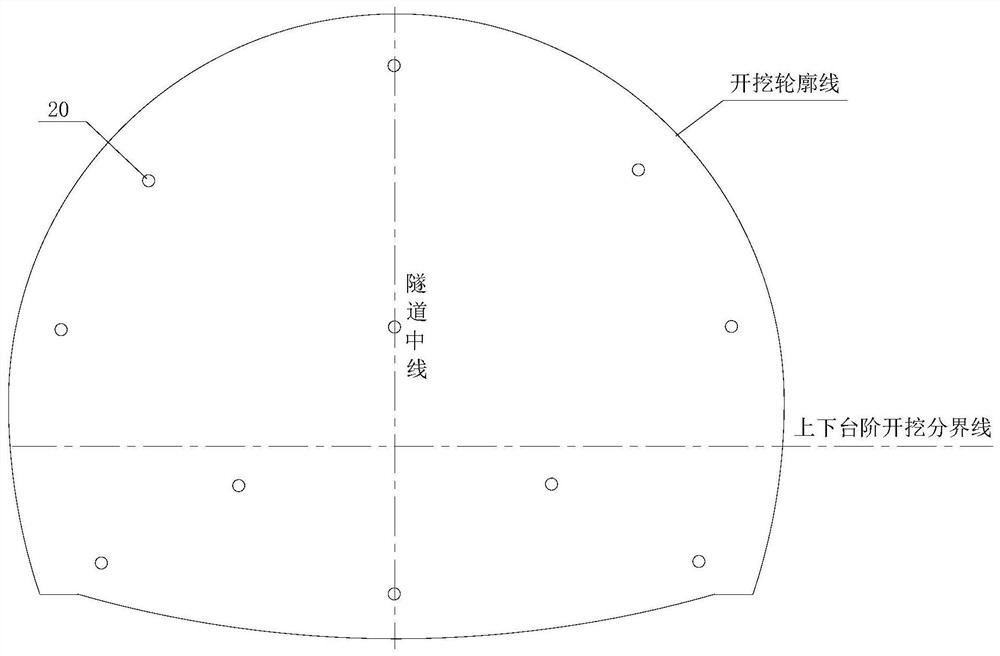

[0024] see Figure 1 to Figure 4 , the construction technology of the tunnel crossing the rockburst section and the superimposed section of the low gas area of the present invention adopts the excavation method of upper and lower steps, and includes the following steps:

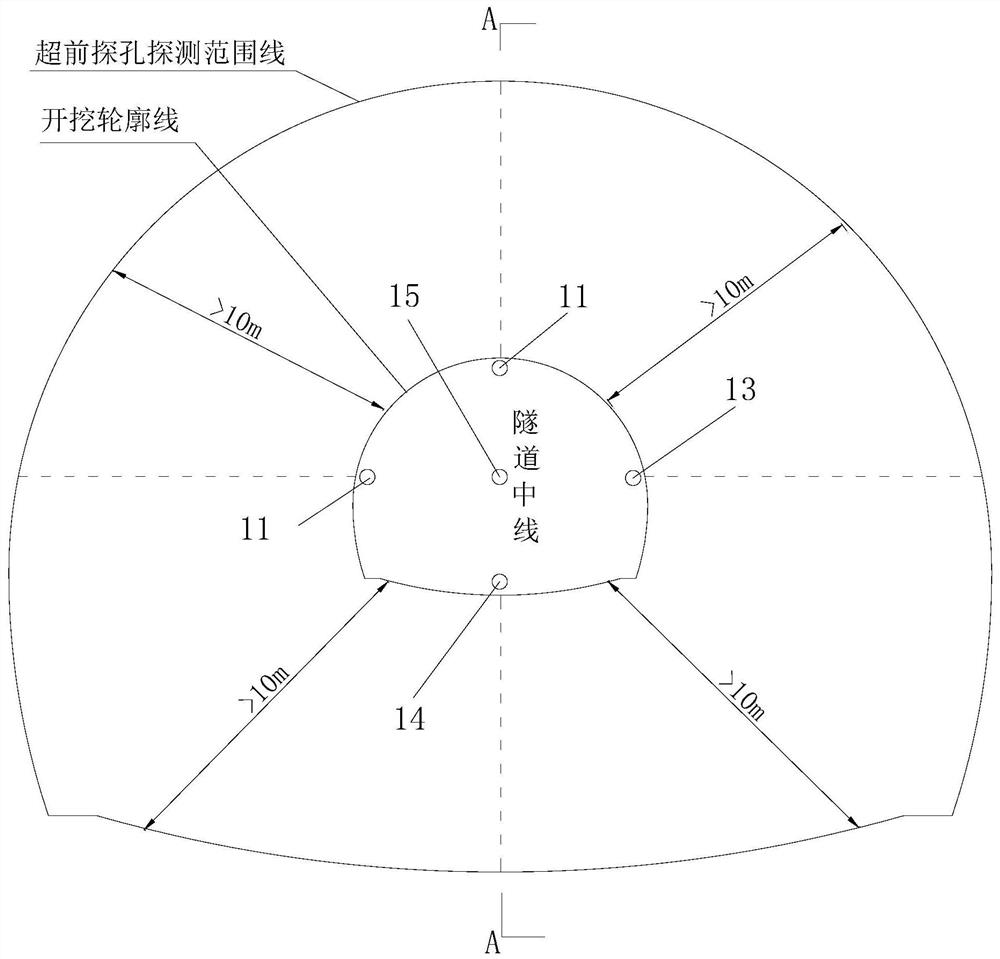

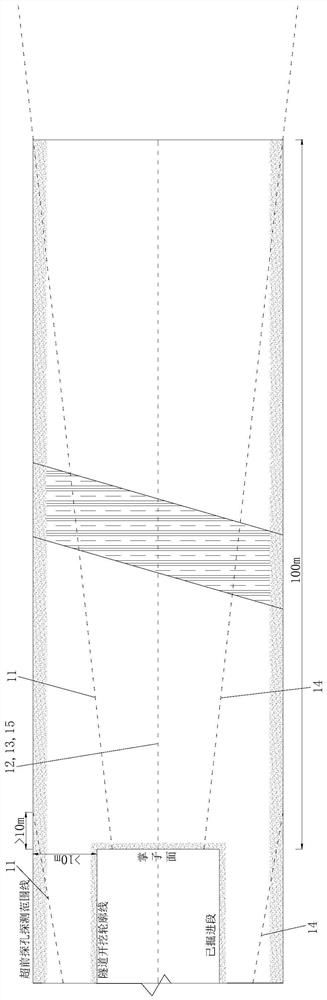

[0025] Step 1. Before the excavation of the main tunnel in the superimposed section of the rockburst section and the low gas area, the geological radar method combined with the advanced drilling method is used to verify the advanced geological forecast, and initially determine whether there is coal seam or gas ahead; the advanced drilling method is to use the coal mine Drill five advance probe holes 11, 12, 13, 14, 15 on the tunnel face with a fully hydraulic tunnel drilling rig. The diameter of the advance probe holes is φ76mm, and four advance probe holes 11, 11, 12, 13, 14, arrange an advanced soundi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com