High-strength end face positioning compact turbine rotor device of turbocharger

A turbocharger and turbine rotor technology, which is applied to pump devices, components of pumping devices for elastic fluids, machines/engines, etc. To solve problems such as long length, cumbersome inspection and assembly processes, etc., to reduce the difficulty of processing, reduce the difficulty of manufacturing and material costs, and reduce the failure mode of shafting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

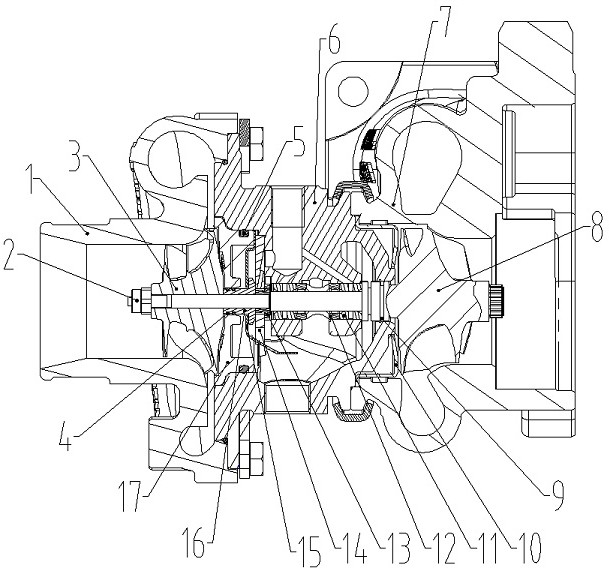

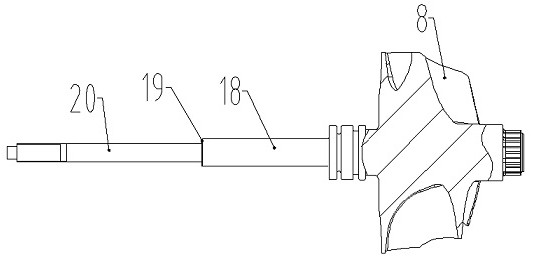

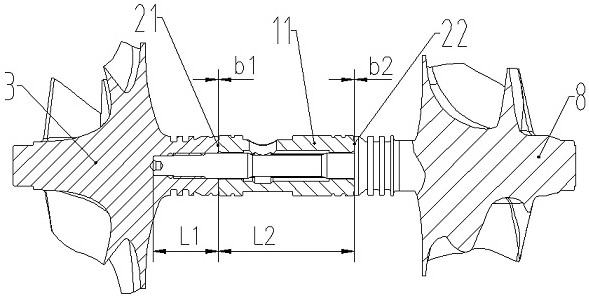

[0037] Example: See Figure 3-8A high-strength end surface of a turbocharger is positioned, including a floating bearing 11, a central portion of the floating bearing 11 having a bearing internal hole 45 having a turbine rotor 8 on one side of the floating bearing 11, One side of the turbine rotor 8 is integrated with a rotor shaft 18, and one end of the rotor shaft 18 is fitted within the bearing inner hole 45, and the other side of the floating bearing 11 is mounted with a compressor impeller 3, and the carrier impeller. 3 is integrally connected to one side of the floating bearings 11, and the rotor shaft 18 is fixed to the impeller shaft 67 to achieve torque and rotation transfer.

[0038] The rotor shaft 18 includes the application function thereof including the rotor shaft body 181, a first rotor support portion 26, a rotor oil storage portion 31, a second rotor support portion 261, a rotor support portion 26, a rotor support portion 261, a second rotor support portion 26, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com