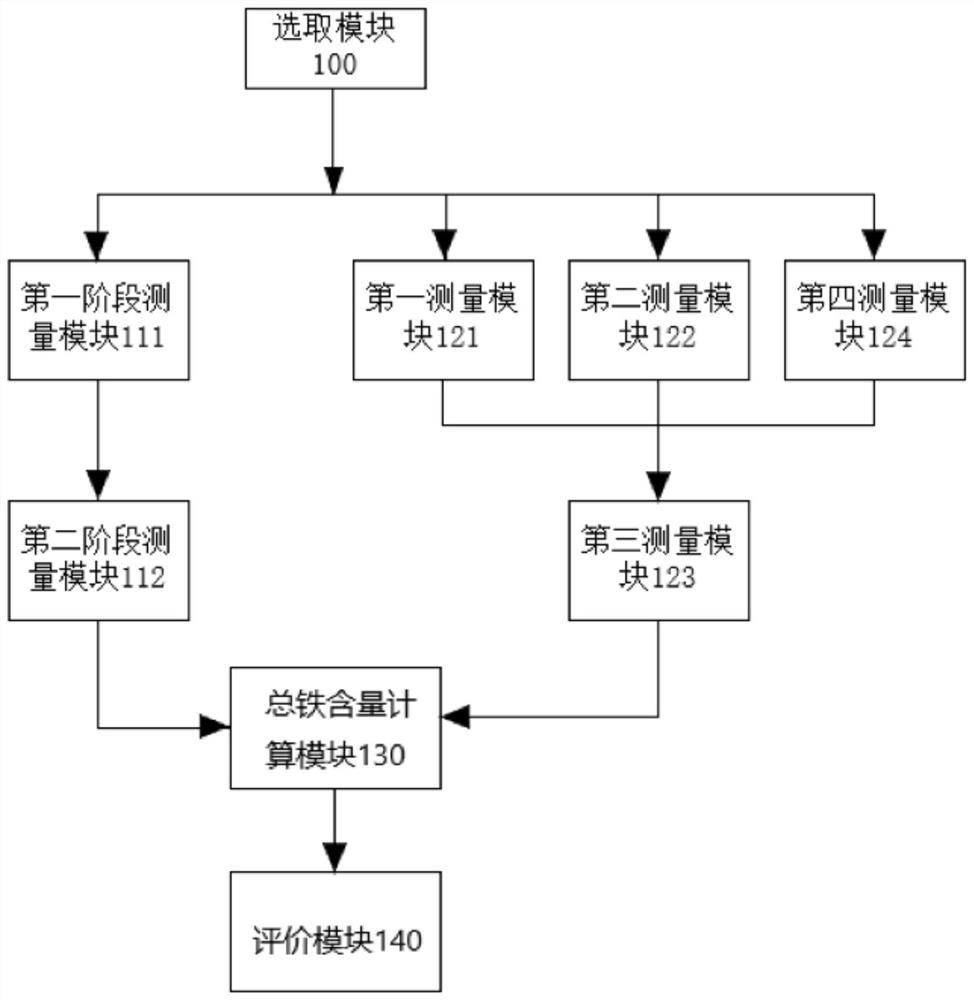

Evaluation method and device for boiler shutdown protection anti-corrosion effect of thermal power generating unit

A technology for boiler shutdown protection and thermal power units, applied in the direction of measuring devices, instruments, data processing applications, etc., can solve the problems of inability to evaluate the anti-corrosion effect of coal-fired boiler shutdown protection, inability to grasp the anti-corrosion situation of the water vapor system of coal-fired boilers, and inability to To characterize issues such as coal-fired boiler outage protection methods, to achieve intuitive and clear results, simple device structure, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

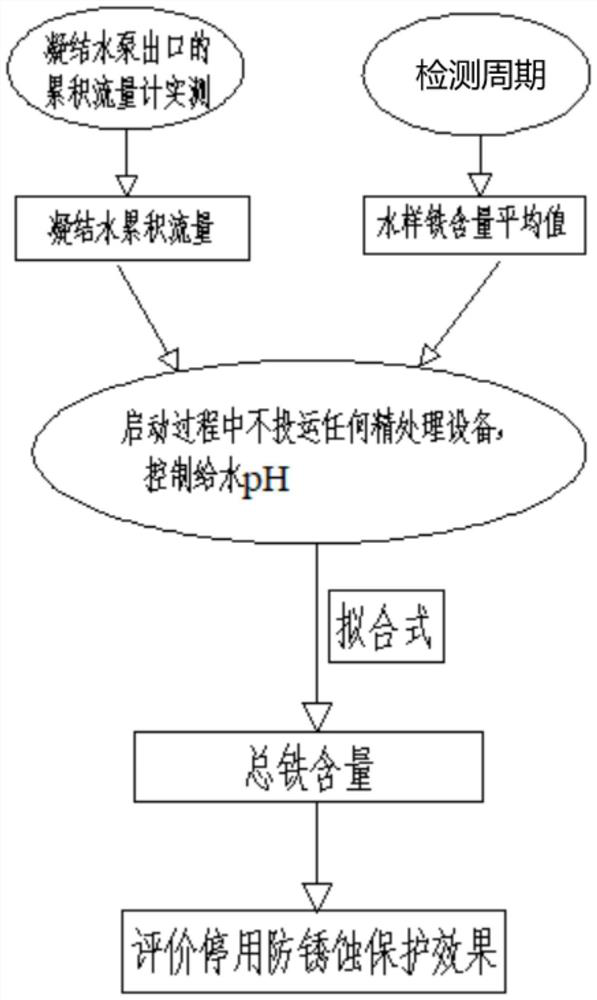

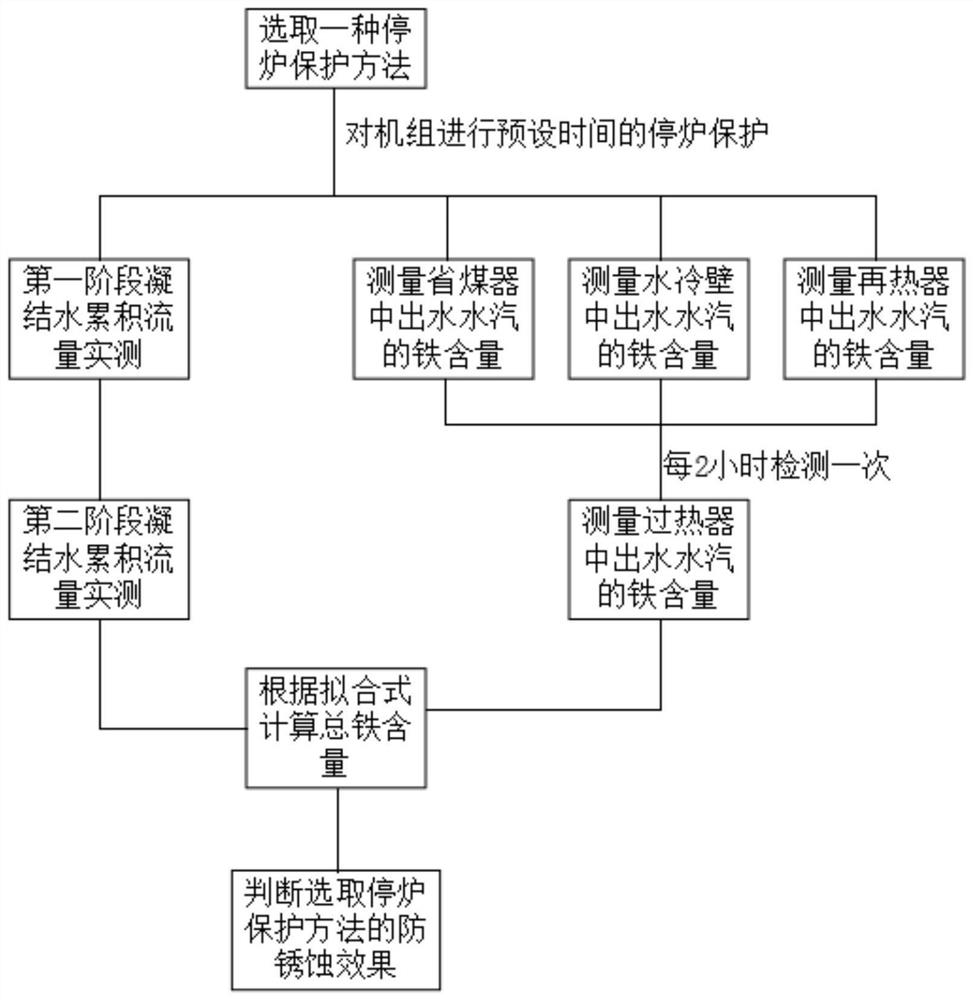

[0086] In this embodiment 1, an ultra-supercritical 660MW DC furnace is selected for shutdown protection, and the coal-fired boiler shutdown protection method adopts the method of increasing the pH value of the feed water for protection. In a certain start-up process, the evaluation method and device of the present invention are used to evaluate the anti-corrosion effect of coal-fired boiler shutdown protection under different shutdown protection times, as follows:

[0087] During the start-up process, the fine treatment high-speed mixed bed of the unit is not put into operation, and the condensate water ammonia addition equipment and the feed water ammonia addition equipment are put into operation to control the pH value of the feed water to maintain between 9.5±0.1 and the conductivity to be controlled at 7.0μS / cm ~10.0μS / cm;

[0088] During the entire start-up period from washing in cold weather to grid connection of the unit, samples are taken every 2 hours and at importan...

Embodiment 2

[0108]In an ultra-supercritical 660MW DC furnace in my country, the coal-fired boiler was protected by nitrogen filling and by increasing the pH value of the feed water during the two shutdowns. In the start-up process after two out-of-service protections, this method is used to evaluate the anti-corrosion effect of coal-fired boiler out-of-service protection: equipment and feedwater ammonia addition equipment, to ensure that the pH of the feedwater is controlled between 9.5±0.1 and the conductivity is controlled between 7.0μS / cm and 10.0μS / cm; Sampling and testing the iron content and other indicators in the water vapor and water samples at the important nodes of flushing and grid connection, and at the same time record the cumulative flow of condensed water until the unit is connected to the grid.

[0109] Nitrogen gas protection method is used: the unit starts after about 179 days of shutdown protection: at the end of hot flushing, the cumulative flow at the outlet of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com