Composite insulator defect diagnosis method based on U-net segmentation

A composite insulator and defect diagnosis technology, applied in neural learning methods, image analysis, image data processing, etc., can solve problems such as difficulty in meeting the efficiency and accuracy of composite insulators, slow detection efficiency, and large influence of human subjective factors, and achieve improvement. The effect of continuous power supply capability and improved inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

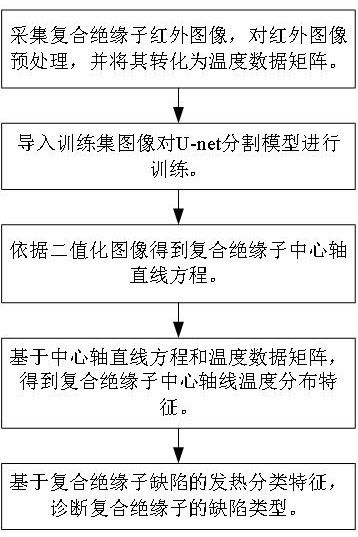

[0035] Please refer to figure 1 , the present invention provides a composite insulator defect diagnosis method based on U-net segmentation, comprising the following steps:

[0036] Step S1: Use a UAV equipped with an infrared thermal imager to inspect composite insulators on 110kV and above transmission lines to obtain a large number of infrared images, analyze the corresponding temperature data matrix of each infrared image, and establish an infrared image sample of composite insulators Library;

[0037] Preferably, in this embodiment, the temperature matrix analysis steps are as follows:

[0038] Step (1): Use the Thermal SDK development tool to extract the temperature information of the infrared image.

[0039] Step (2): Decode the extracted byte-type temperature matrix information and perform bit operations to obtain the Raw matrix.

[0040] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com