High-safety polymer flexible package lithium ion battery

A lithium-ion battery, high-safety technology, applied in the manufacture of battery electrodes, secondary batteries, electrolyte batteries, etc., can solve problems such as thermal runaway, explosion, product damage to personal safety, etc., to reduce battery performance, reliable reaction mechanism, Avoid the effects of thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

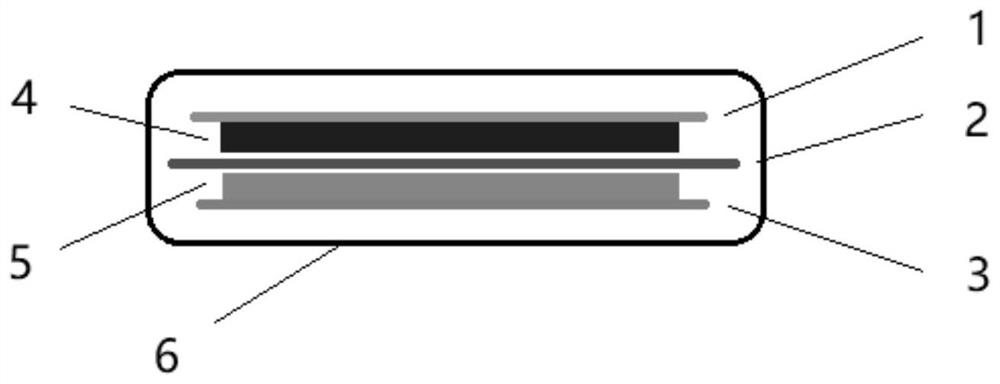

[0027] Preparation of shape memory alloy current collector: select a TiNi shape memory alloy with a thickness of 0.1mm and a phase transition temperature of 80°C; pre-deform the TiNi alloy sheet into a wavy cross-section using a special mold, such as image 3 . Then keep the shape and put it in a 450°C environment for 4 hours, and then cool it naturally. The cooled TiNi shape memory alloy is flattened again to become figure 2 the shape shown.

[0028] Negative electrode preparation: mix graphite, conductive carbon black, polymethylcellulose sodium, styrene-butadiene rubber emulsion with deionized water in a ratio of 94:1:1.5:2.5 to form a slurry, and then mix it in the prepared shape memory The surface of the alloy current collector is coated with an appropriate amount of negative electrode slurry, and then vacuum-dried at 60°C.

[0029] Manufacture of soft-pack batteries: Assemble the negative and positive electrodes prepared by the above method, separator, electrolyte, a...

Embodiment 2

[0032] Preparation of the shape memory alloy current collector: select a TiNi shape memory alloy with a thickness of 0.15 mm and a phase transition temperature of 105° C.; pre-deform the TiNi alloy sheet into a concave-convex texture with a special clamp. Then keep the shape and put it in a 600°C environment for 4 hours, and then cool it naturally. The cooled TiNi shape memory alloy is flat-pressed into figure 2 Planar form shown.

[0033] Such as figure 1 , the prepared shape memory alloy current collector is coated with negative electrode slurry, and then assembled with positive electrode, separator, electrolyte, and aluminum-plastic composite film to form a flexible lithium-ion battery 1 .

[0034] For the soft-packaged lithium-ion battery in this embodiment, when the internal temperature reaches 105°C during the abuse test, the negative electrode shape memory alloy current collector will deform and return to the shape of the high-temperature state of the shape memory al...

Embodiment 3

[0036] Preparation of shape memory alloy current collector: select a TiNi shape memory alloy foil coil with a thickness of 0.008mm and a phase transition temperature of 85°C; emboss the TiNi shape memory alloy foil coil using a roller press mold, and its surface appearance Such as Figure 6 . Heating at the same time during the embossing process keeps the rolling embossing die at 200°C, and the rolling speed is kept at a relatively slow level to ensure that the TiNi shape memory alloy foil coil can remain deformed for more than 30 minutes during the embossing process. After the high temperature zone, after the coil material drops to normal temperature, it will be flattened into a coil material after being rolled with a smooth surface.

[0037] The prepared shape memory alloy current collector coil is coated with negative electrode slurry using large-scale production coating equipment, and dried at a temperature below 80°C to obtain a negative electrode sheet, and then combine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com