Traceable polylactic acid/rifampicin drug-loaded microspheres and preparation method thereof

A technology of drug-loaded microspheres and polylactic acid, which is applied in the field of biomedicine, can solve the problems of patient tolerance, short drug release time, and failure to meet bone repair, and achieve good encapsulation efficiency, good drug loading, and process simple and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

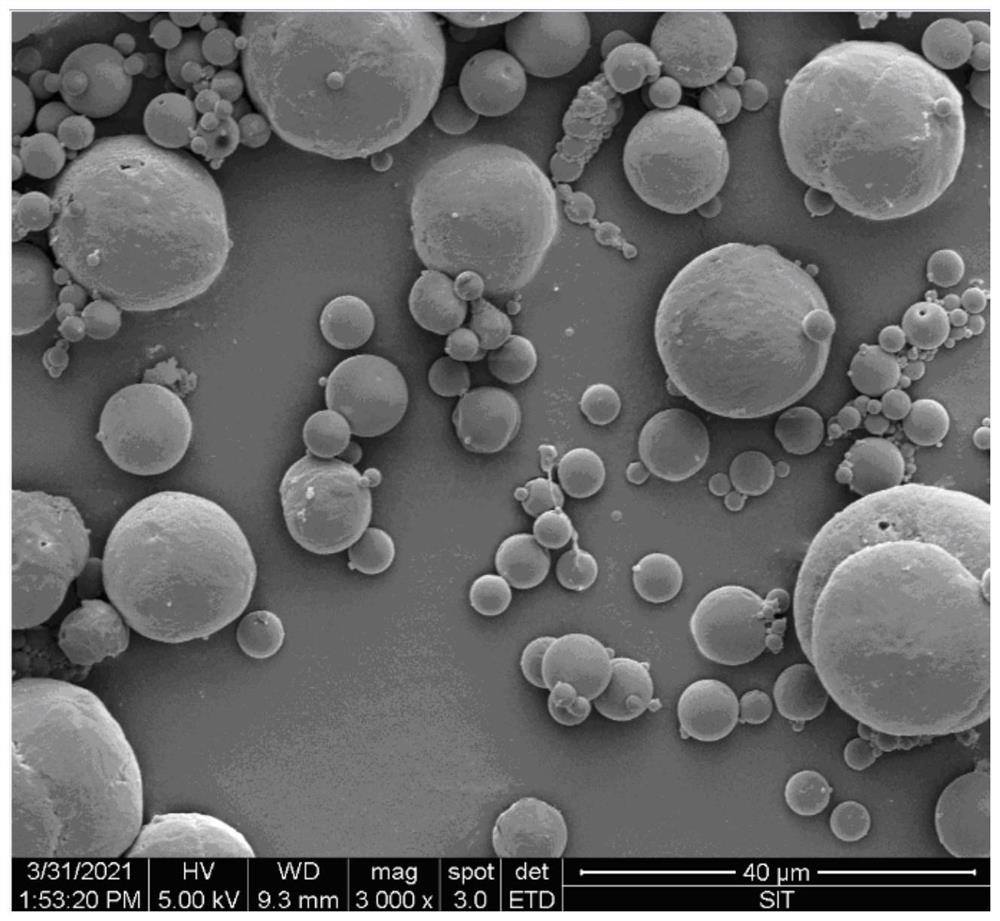

Embodiment 1

[0036] Dissolve about 5g of PLA in about 40mL of dichloromethane until clear and transparent. Then add 0.25g of Span-80 and 10mg of rifampicin for ultrasonic emulsification for 30min to obtain an emulsion; the obtained emulsion is poured into 400mL concentration of 1% PVA (polyvinyl alcohol) aqueous solution, with a rotating speed of 5000r / min Shear and disperse in a high-speed shear emulsifier for 3 minutes to obtain an oil-in-water (O / W) emulsion; magnetically stir the obtained (O / W) emulsion at room temperature, and simultaneously add 5 g of ioversol with a concentration of 1% for imaging After 0.5h, add 1g of sodium tripolyphosphate (TPP) dropwise, and then continue to stir for 3h to completely volatilize the organic solvent, solidify and form the microspheres, and obtain PLA two-layer composite drug-loaded microspheres; place them in 40mL dissolved 5g of PLA in dichloromethane solution, ultrasonically oscillated for 30min at 25°C, and then centrifuged and washed to obtain...

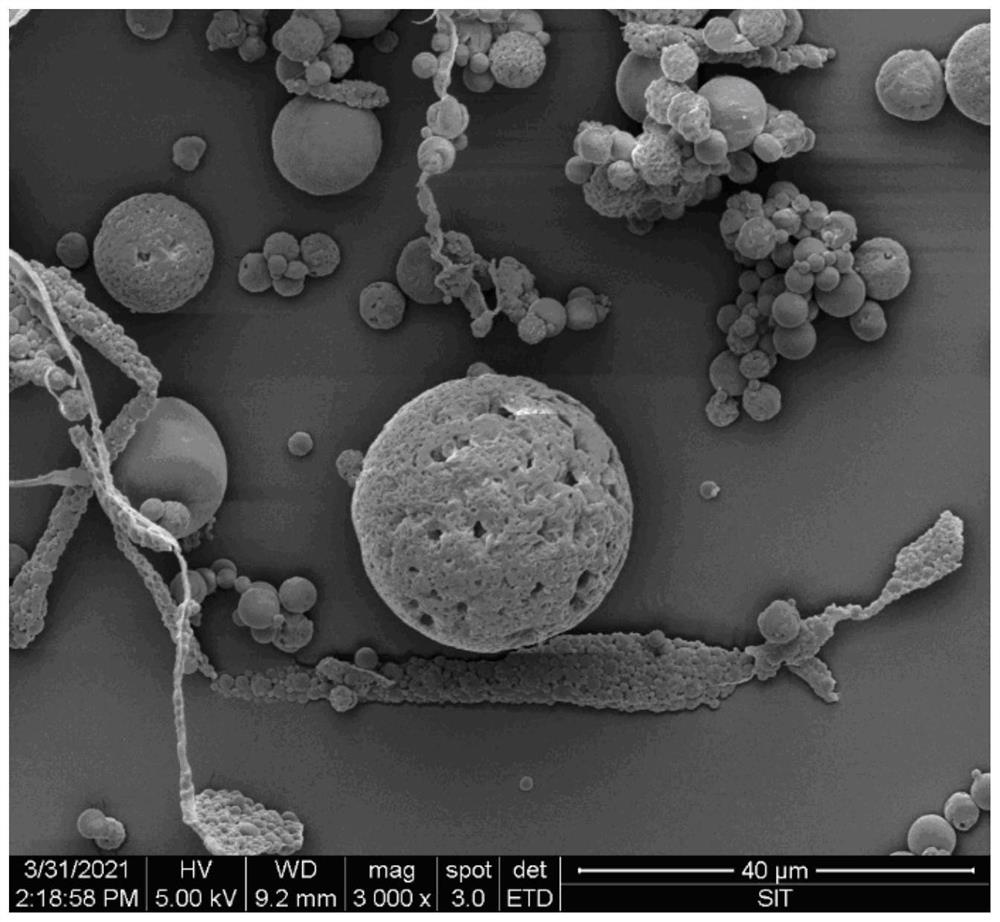

Embodiment 2

[0038] Dissolve about 5g of PLA in about 40mL of dichloromethane until clear and transparent. Then add 0.25 g of Span-80 and 10 mg of rifampicin for ultrasonic emulsification for 30 min to obtain an emulsion; pour the obtained emulsion into 400 mL of 1% PVA (polyvinyl alcohol) aqueous solution at a speed of 5000 r / min Shear and disperse for 3min in a high-speed shear emulsifier to obtain an oil-in-water (O / W) emulsion; the obtained (O / W) emulsion is magnetically stirred at room temperature, and 5g of iodophor with a mass concentration of 1% is added dropwise Alcohol contrast agent solution, add 1g sodium tripolyphosphate (TPP) dropwise after 0.5h, and then continue to stir for 3h to completely volatilize the organic solvent, solidify the microspheres, and obtain PLA two-layer composite drug loading; put it in 40mL dissolved In 5 g of PLA in dichloromethane solution, ultrasonically oscillate at 25°C for 30 min, then centrifuge and wash to obtain three-layer composite drug-loade...

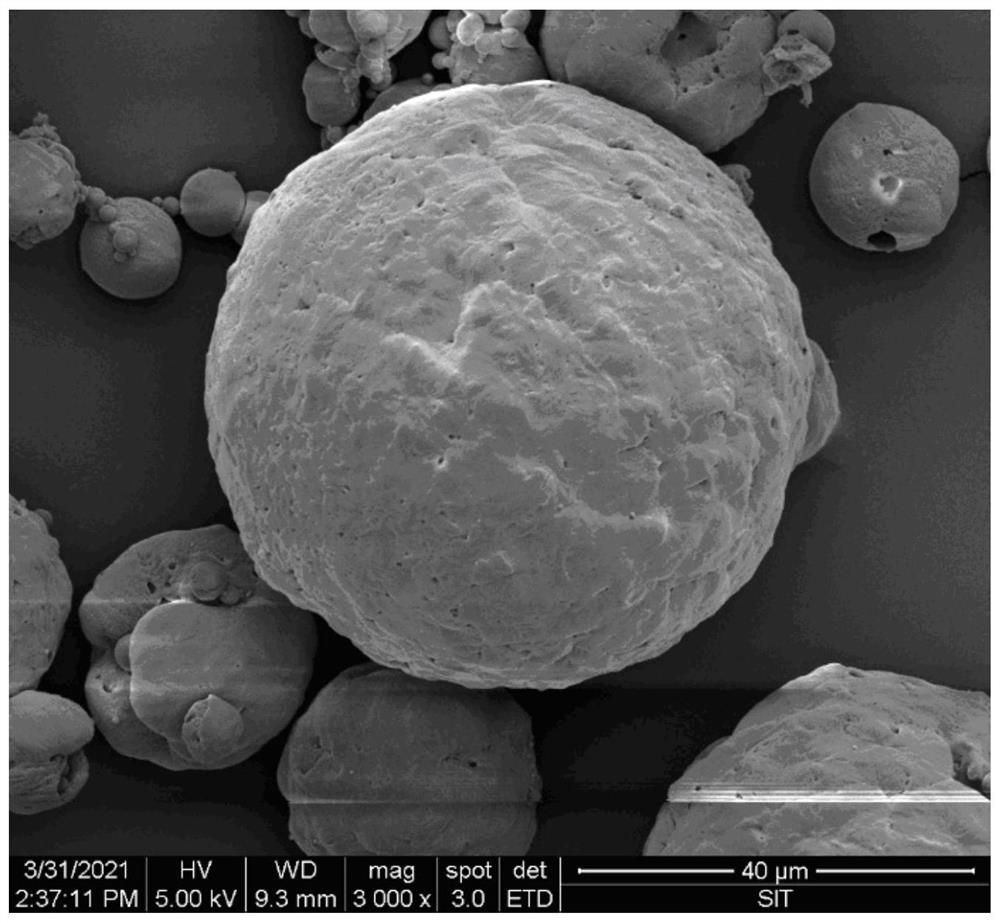

Embodiment 3

[0040] Dissolve about 5g of PLA in about 40mL of dichloromethane until clear and transparent. Then add 0.25g of Span-80 and 10mg of rifampicin for ultrasonic emulsification for 30min to obtain an emulsion; the obtained emulsion is poured into 400mL concentration of 1% PVA (polyvinyl alcohol) aqueous solution, with a rotating speed of 5000r / min In a high-speed shear emulsifier, shear and disperse for 3 minutes to obtain an oil-in-water (O / W) emulsion; the obtained (O / W) emulsion is magnetically stirred at room temperature, and 5 g of ioversol with a mass concentration of 1% is added dropwise Contrast agent solution, add 1g sodium tripolyphosphate (TPP) dropwise after 0.5h, and then continue to stir for 3h to completely volatilize the organic solvent, solidify the microspheres, and obtain PLA two-layer composite drug loading; put it in 40mL and dissolve 5g In the dichloromethane solution of PLA, oscillate ultrasonically at 25°C for 30 minutes, then centrifuge and wash to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com