Antibacterial and breathable fabric and processing technology thereof

A processing technology and fabric technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of easy sweating, bacteria breeding in sweat, and single function, so as to improve air permeability, improve moisture absorption and quick-drying effect, The fabric is comfortable to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

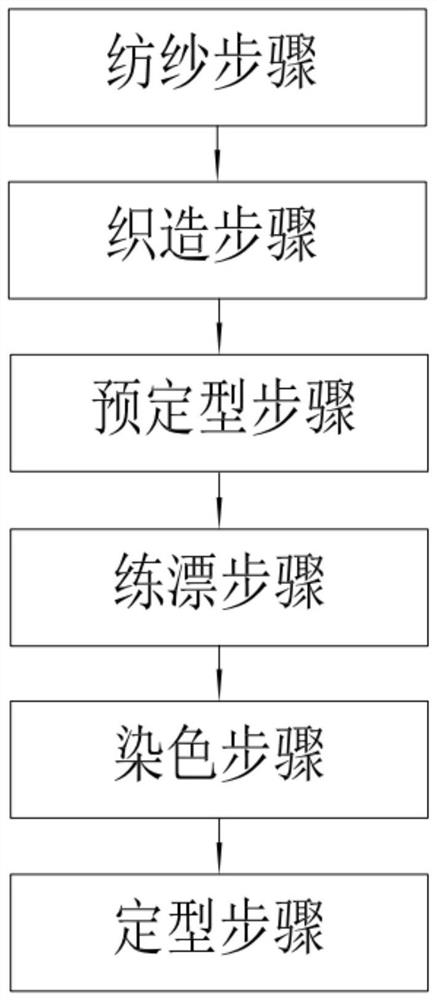

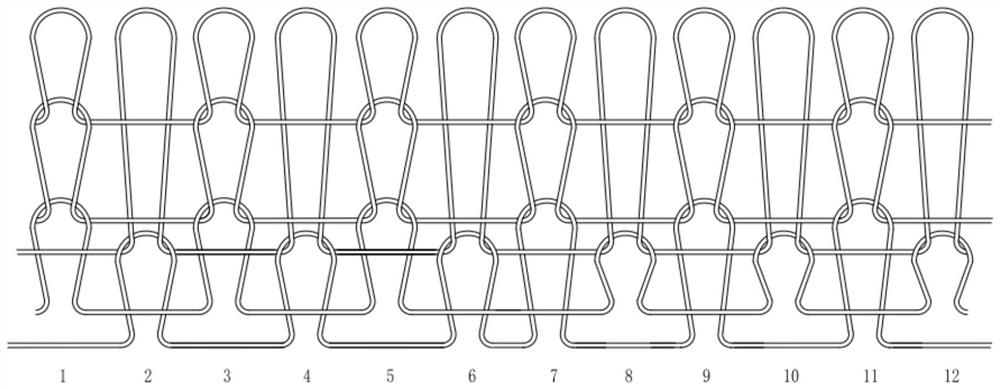

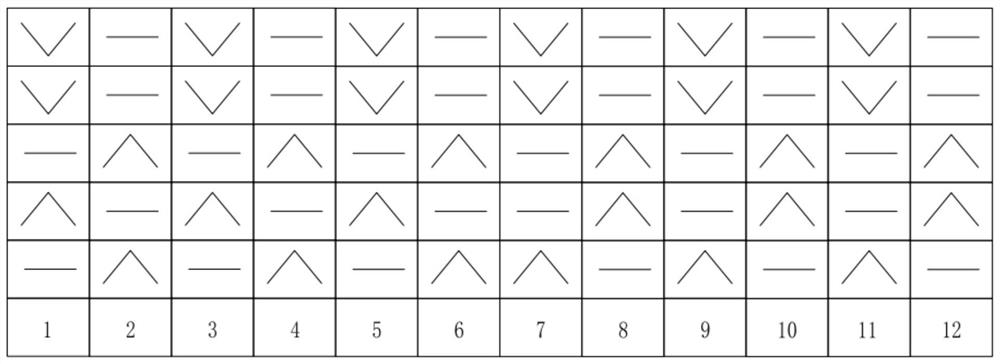

[0032] refer to figure 1 , the fibers used for spinning are spun into yarns through a spinning machine, at least one of which contains Conlon fibers; the specific yarn with Conlon fibers is 75D / 72FDTY Condy yarn, and Conlon fibers are both improved The three-dimensional shape of the grooved fiber cross-section greatly improves the moisture absorption and quick-drying effects of the fabric products, and silver-based antibacterial substances are added inside the fibers, which can quickly kill Staphylococcus aureus and Klebsiella pneumoniae that cause sweat odor , Escherichia coli and other harmful bacteria; at the same time, because of its non-exudative bactericidal function, it will not harm beneficial bacteria and will not irritate and infect the skin, thus bringing extraordinary comfort to the wearer; except for 75D / 72FDTY Condi yarn There are also 75D / 36FDTY yarns, high-elastic yarns, etc. 75D / 36FDTY yarns have high toughness, which can enhance the fabric's stiffness and ach...

Embodiment 2

[0036] The difference between this embodiment and Embodiment 1 is that in the weaving process of the jacquard weave, the yarn threading methods of the 1st, 3rd, 5th, 7th, 9th, 11th, and 12th roads are: wear 75D / 36FDTY yarns and high-elastic yarns For the composite yarn of thread, the threading method of the 2nd, 4th, 6th, 8th, and 10th yarns is: wear the composite yarn of 75D / 72FDTY Condy yarn and high-elastic yarn, specifically, the high-elastic yarn and 75D / 36FDTY yarn Thread, high-elastic yarn and 75D / 72FDTY condy yarn form a composite yarn through S-twisting. Under the action of the composite yarn, the fabric after weaving is more elastic and more comfortable to wear.

Embodiment 3

[0038]The difference between this embodiment and embodiment 2 is that in the knitting process of the jacquard weave, the yarn threading methods of the 1st, 3rd, 5th, 7th, 9th, 11th, and 12th roads are: wear 75D / 36FDTY yarn and high elastic yarn For the covered yarn of the thread, the yarn threading method of the 2nd, 4th, 6th, 8th, and 10th is: wear the covered yarn of 75D / 72FDTY Condy yarn and high-elastic yarn, and specifically use the high-elastic yarn as the core yarn , and then spirally wind 75D / 36FDTY yarn or 75D / 72FDTY Condi yarn on the core yarn to form a covering yarn, and use the high-elastic yarn as the core yarn to greatly improve the elasticity of the covering yarn, so that the weaving after forming The fabric has more stretch and is more comfortable to wear.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com