High-temperature particle waste heat recycling device and method for waste incineration power plant

A technology of waste incineration and waste heat recovery, applied in the direction of combustion method, heating method, steam engine device, etc., can solve the problems of low-temperature heat loss of tail gas exhaust, waste of resources, heat loss of boiler combustion, etc., to increase heat supply and heat supply income, reduce cooling water consumption, and improve economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

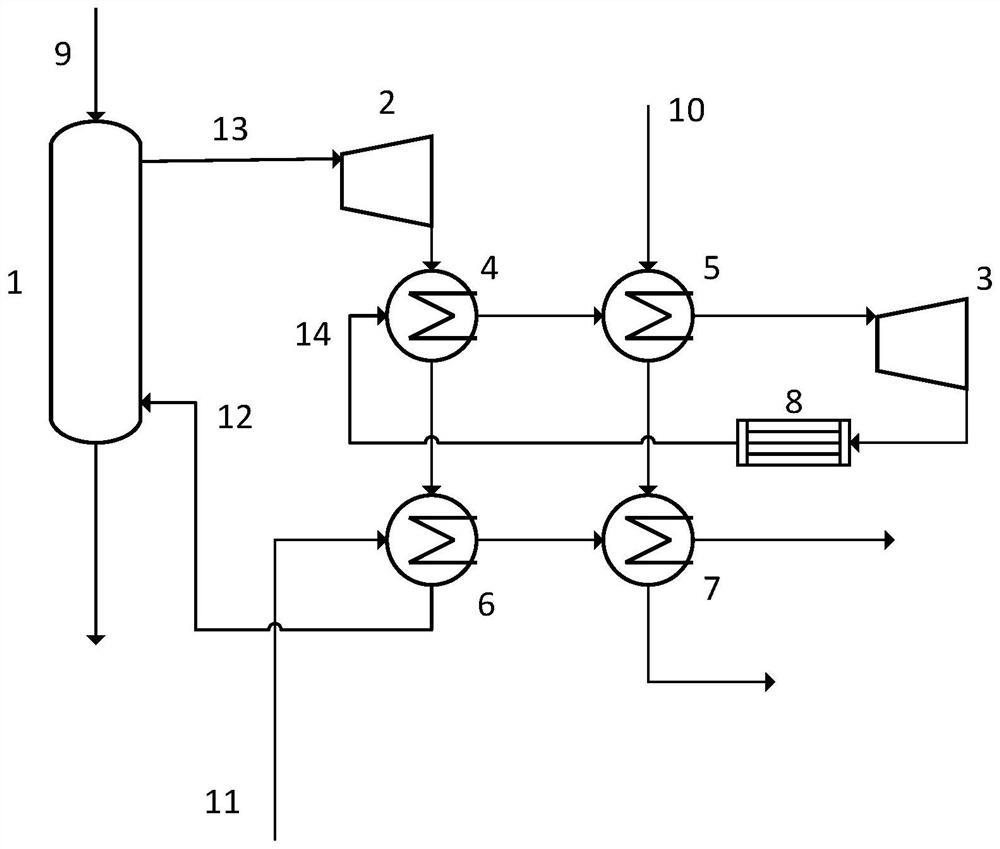

[0024] A waste heat recovery and utilization device for high-temperature particles in a waste incineration power plant, including a waste heat boiler 1 connected to the bottom of the incinerator in the waste incineration power plant, and the waste heat boiler 1 is used to exchange heat with the high-temperature particles 9 at the bottom of the incinerator in the waste incineration power plant. heat exchange.

[0025] The outlet of the heat exchange medium of the waste heat boiler 1 is connected to the inlet of the first steam turbine 2, and the bottom of the waste heat boiler 1 is provided with a particle recovery device for processing and recovering the high temperature particles 9 after heat exchange. The outlet of the first steam turbine 2 communicates with the first inlet of the first hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com