Wafer multilayer stacking bonding method

A multi-layer stacking and wafer technology, applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve problems such as wafer fragments, avoid splits, have broad application prospects and market potential, and improve assembly efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

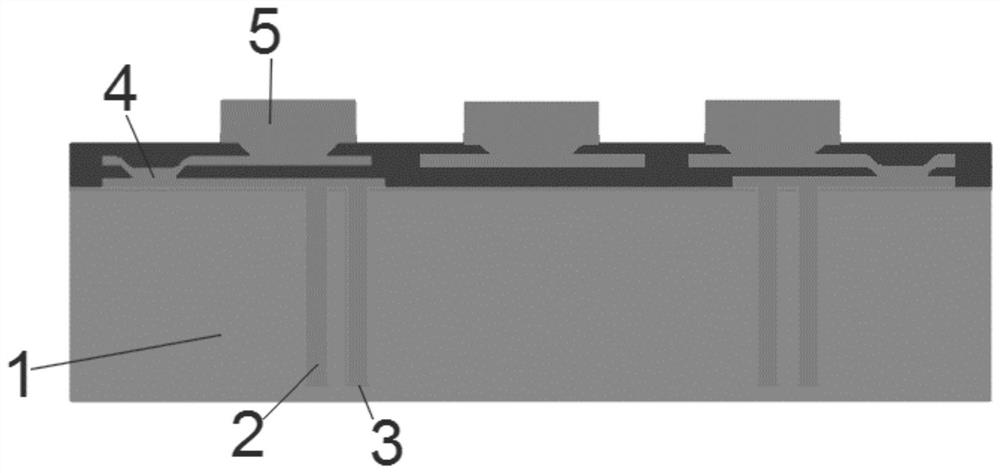

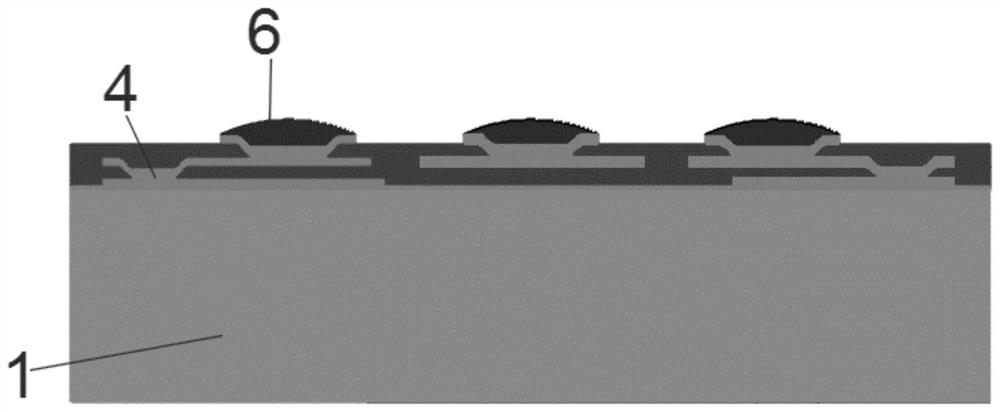

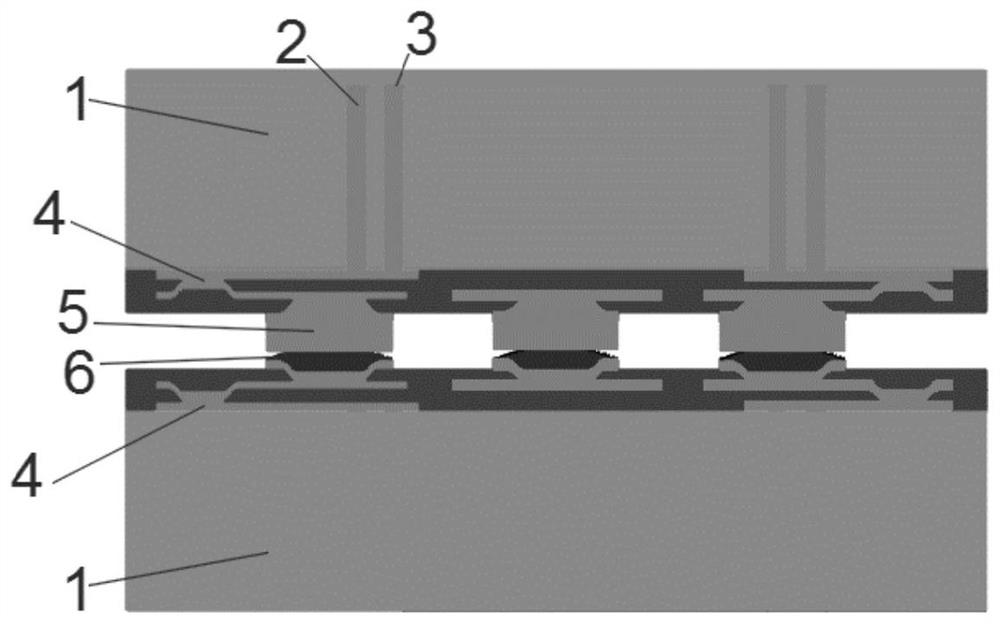

[0040] In this embodiment, the used wafer is a 4M asynchronous SRAM (static memory) wafer, which is finally a 3-layer SRAM wafer bonding product, such as Figure 5 shown. The 3-layer SRAM wafer bonding method includes the following steps: the process is as follows Figure 7 as shown,

[0041] Step 1. The first layer of wafer is only re-wiring and bump preparation on the front side, lead out the pad, and the front side is re-wiring to 3 layers, and the bump is electroplated SnAg, with a height of 3 μm;

[0042] The second layer wafer and the third layer wafer first complete the front rewiring and bump preparation, the number of rewiring layers is 3 layers, the front bump is electroplated Cu, and the height is 5 μm;

[0043] Step 2. The SnAg bumps on the front of the first layer of wafer are metal-bonded with the Cu bumps on the front of the second layer of wafer. The bonding temperature is 260°C, the time is 30 minutes, the bump opening ratio is 1.5%, and the bonding pressure...

Embodiment 2

[0052] Except the following content, all the other content are the same as embodiment 1.

[0053] The TSV diameter is 5 μm and the depth is 50 μm;

[0054] The bonding temperature is 240°C, the bonding time is 60min, the bump opening ratio is 3.5%, and the bonding pressure is 6000N;

[0055] The front rewiring layer is 2 layers, and the rear rewiring layer is 4 layers.

[0056] In step 5, in the metallization layer on the back of the second wafer, the adhesion layer is 0.5 μm Ti, the barrier layer is 1 μm Cu, and the wetting layer is 2 μm Ni;

[0057] In step 8, in the metallization layer on the back of the third wafer, the adhesion layer is 0.1 μm Ti, the barrier layer is 2 μm Cu, and the wetting layer is 5 μm Cu;

Embodiment 3

[0059] In this embodiment, the used wafer is a 4M asynchronous SRAM (static memory) wafer, and finally is a 5-layer SRAM wafer bonding product, such as Figure 6 As shown, the preparation process is as follows Figure 7 shown.

[0060] Step 1. The first layer of wafer is only re-wiring and bump preparation on the front side, lead out the pad, and the front side is re-wiring to 2 layers, and the bump is electroplated Cu, with a height of 3 μm;

[0061] The second layer wafer and the third layer wafer first complete the front rewiring and bump preparation, the number of rewiring layers is 3 layers, the front bump is electroplated Cu, and the height is 5 μm;

[0062] Step 2. The Cu bumps on the front side of the first layer wafer are metal-bonded with the Cu bumps on the front side of the second layer wafer. The bonding temperature is 400°C, the bonding time is 90 minutes, the bump opening ratio is 2%, and the bonding pressure is 20kN; through the Cu-Cu metal bonding process, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com