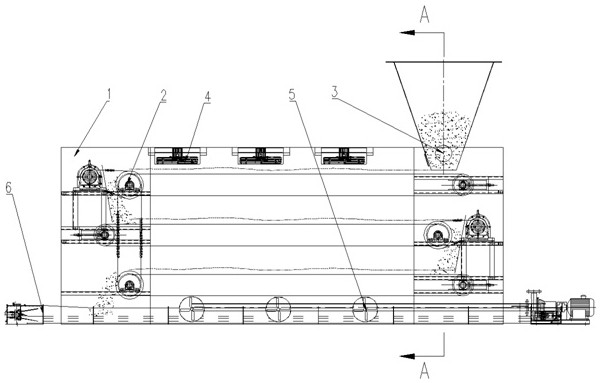

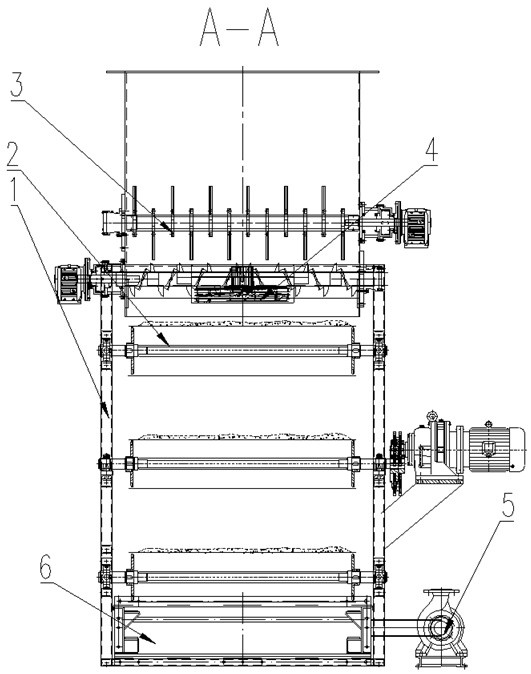

Belt type air-drying system device and air-drying method

A system device and dust removal system technology, applied in the field of belt-type air-drying and drying system devices, can solve problems such as direct use, production, high cost of use, complicated operation procedures, etc., and achieve compact structure, low environmental pollution, and work. The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

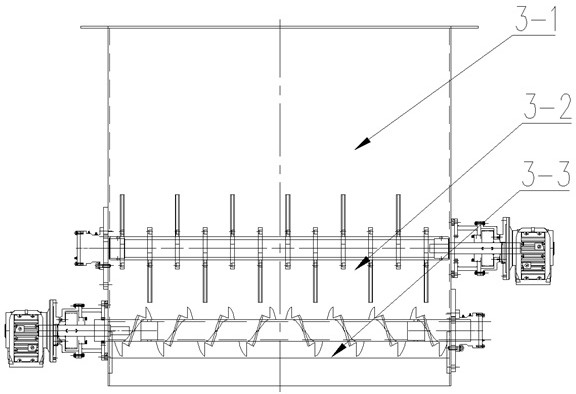

[0085] Embodiment 2: The connection between the net belt 2-4, the transmission shaft 2-3 and the tension shaft 2-5 constitutes the network shaft drive connection, specifically: the network shaft drive connection includes: 2# transmission shaft 2 -3.2, 2# mesh belt 2-4.2, 2# tension shaft 2-5.2 and idler roller 2-6.2; 2# transmission shaft 2-3.2 is installed on the frame on both sides of the bellows through the bearing seat, 2# transmission shaft 2- The shaft head of 3.2 is connected with the reducer, and there is a rubber-covered roller outside the drive shaft. The 2# mesh belt 2-4.2 is wound on the roller, which is the belt transmission mode; the 2# mesh belt 2-4.2 is the mesh belt ∅2.0x∅2.0 x pitch 20x pitch 30, installed between 2# drive shaft 2-3.2 and 2# tension shaft 2-5.2, the bearing seat of 2# tension shaft 2-5.2 is connected on both sides of the bellows through an adjustable coupling On the frame, adjust the tightness of the mesh belt through the tail screw rod of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com