Perforated leather with ramp texture and preparation method thereof

A leather and legal technology, applied in the field of polyurethane material modification and preparation, can solve the problems of singleness and limitations of existing design, which cannot keep up with the development of the industry and the needs of customers, so as to improve the singleness of taste, broaden product types, and improve design Sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

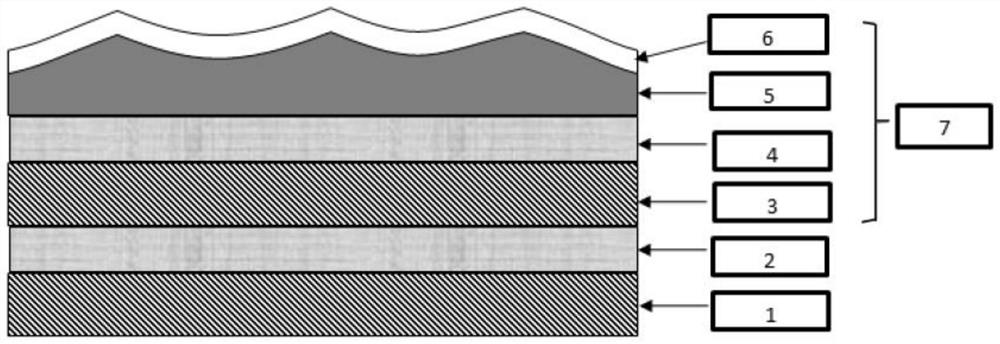

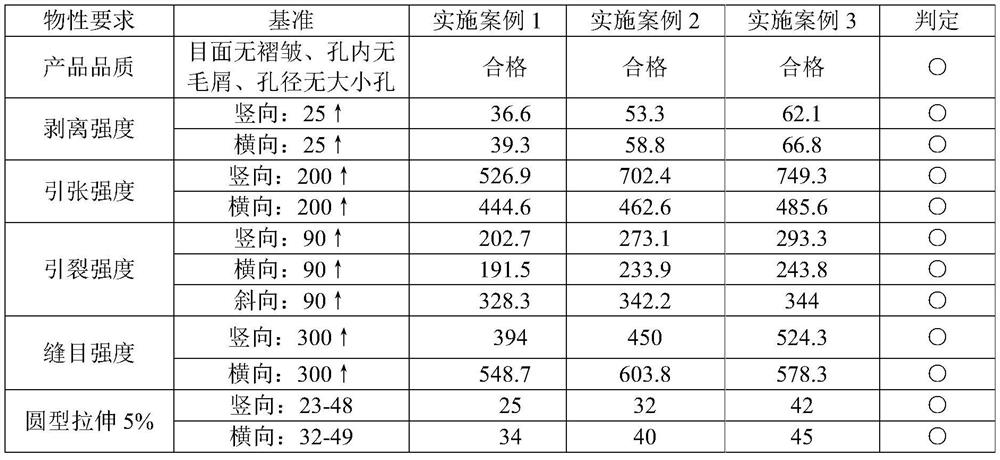

[0031] A gradual perforated leather provided in this embodiment and a preparation method thereof: firstly, the base 7 is processed. The process includes S1 release paper preparation, S2 surface layer 5 coating, S3 foam layer 4 coating, S4 base fabric layer 3 lamination, S5 release paper peeling. Wherein the surface layer 5 and the foam layer 4 are made of polyurethane. The base fabric layer 3 has a thickness ranging from 700 μm to 1100 μm and a weight range of 200 g / m 2 ~400g / m 2 Circular knitted fabrics, warp knitted fabrics, woven fabrics, or non-woven fabrics. The release paper is textured or non-textured, and the surface is PP or silicone oil-coated leather transfer paper. The surface layer 5 includes polyurethane, pigments and dissolution medium; the mass percentages of the material components of the surface layer 5 are: 50.5% to 69.1% polyurethane, 9.9% to 16.5% pigment, and 26% to 28% dissolution medium. The dissolution medium is MEK and DMF. The foam layer 4 inclu...

Embodiment 2

[0041] The difference between the gradient pattern perforated leather provided in this embodiment and its preparation method and that in Embodiment 1 is:

[0042] S8 heat lamination process, use heat lamination machine to carry out the processing of hot melt adhesive layer 2 and base fabric layer 1 on the base blank 6 obtained in step S7. The processing of the hot-melt adhesive layer 2 includes the setting of the temperature of the hot-melt adhesive machine and the temperature of the rollers. The hot-melt adhesive is solid and needs to be melted on a special hot-melt adhesive machine. The temperature of the hot-melt adhesive machine is set to 80 degrees, and the temperature of the roller is set to 80 degrees (the hot-melt adhesive machine is for melting the hot-melt adhesive, and the working roller is for heat preservation. ), the viscosity of the hot melt adhesive is 8500cps. Spread the hot-melt adhesive evenly on the roller, and when the roller rotates, the hot-melt adhesiv...

Embodiment 3

[0044] The difference between the gradient pattern perforated leather provided in this embodiment and its preparation method and that in Embodiment 1 is:

[0045] S8 heat lamination process, use heat lamination machine to carry out the processing of hot melt adhesive layer 2 and base fabric layer 1 on the base blank 6 obtained in step S7. The processing of the hot-melt adhesive layer 2 includes the setting of the temperature of the hot-melt adhesive machine and the temperature of the rollers. The hot-melt adhesive is solid and needs to be melted on a special hot-melt adhesive machine. The temperature of the hot-melt adhesive machine is set to 85 degrees, and the temperature of the roller is set to 85 degrees (the hot-melt adhesive machine is for melting the hot-melt adhesive, and the working roller is for heat preservation. ), the viscosity of the hot melt adhesive is 10000cps. Spread the hot-melt adhesive evenly on the roller, and when the roller rotates, the hot-melt adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com