Soil remediation agent and preparation method thereof

A soil remediation agent and mineral soil technology, applied in the field of soil remediation, can solve problems that are difficult to solve comprehensively and systematically, and achieve the effects of improving immunity and resistance to diseases and insect pests, promoting microbial reproduction, and increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a kind of preparation method of soil remediation agent, comprises the following steps:

[0022] 1) react after mixing coal ash, ore soil and acid solution to obtain slurry;

[0023] 2) After mixing the slurry, organic waste and microorganisms, they are stacked and fermented in sequence to obtain a soil remediation agent.

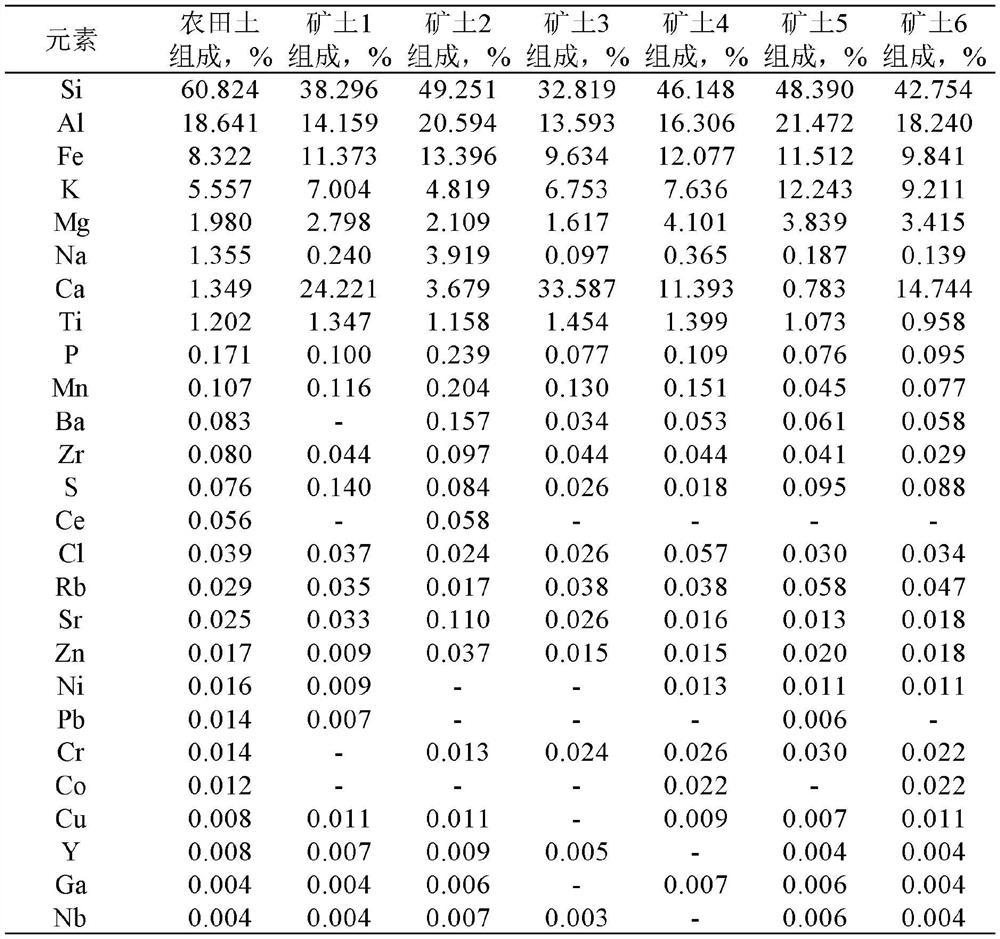

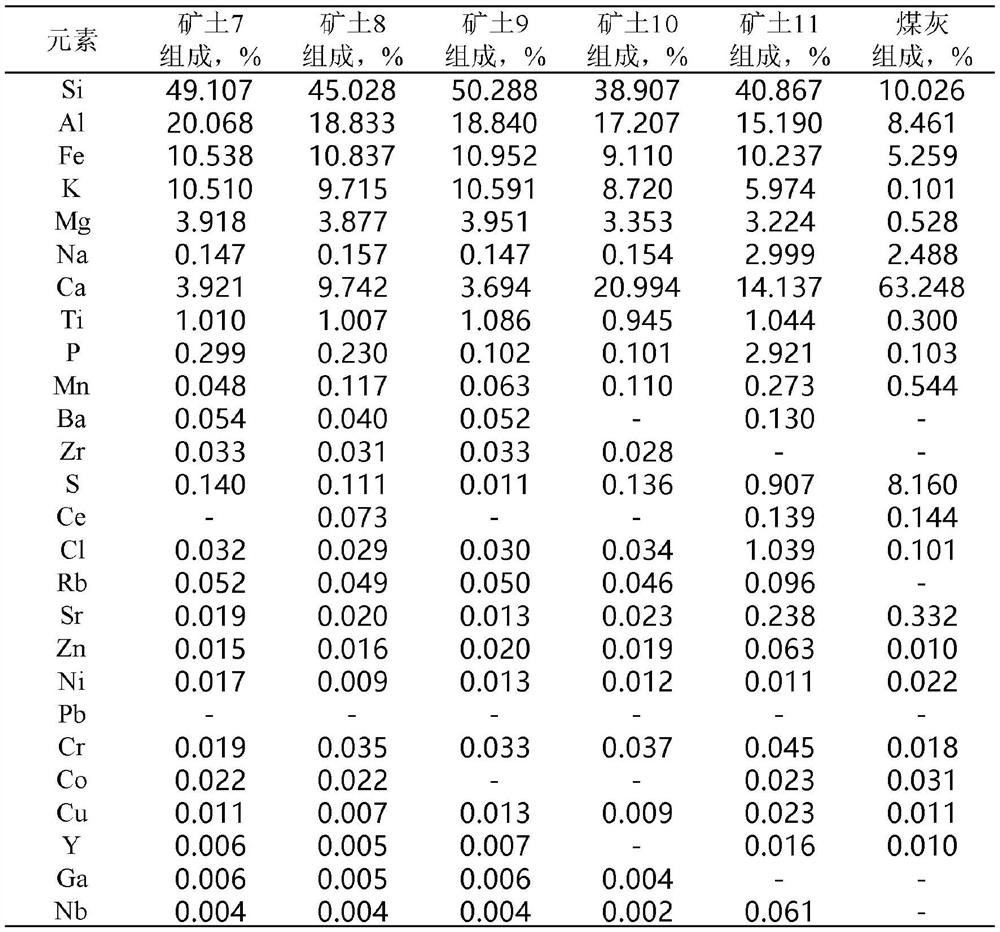

[0024] The mass ratio of coal ash and ore soil in step 1) of the present invention is preferably 1 to 2:2 to 4, more preferably 1:2; the ore soil is preferably an ore soil mixture composed of various ore soils, ore soil In the mixture, each ore soil is preferably mixed in an equal mass ratio; the acid solution is preferably a sulfuric acid solution or a nitric acid solution.

[0025] The sulfuric acid solution of the present invention is preferably an aqueous solution of concentrated sulfuric acid, and the mass concentration of the concentrated sulfuric acid is preferably 95-98%; in the aqueous solution of concentrated sulfuric...

Embodiment 1

[0044]The ore soil 4, ore soil 6 and coal ash in Table 1 are mixed according to the mass ratio of 1:1:1, and the obtained mixture is called mine coal ash. Mix 50L of concentrated sulfuric acid (mass concentration: 97%) and 550L of water to obtain a sulfuric acid solution, gradually add coal ash to the sulfuric acid solution at room temperature until the pH value reaches 5, stir for 5 hours to fully react, and obtain a slurry. Mix the slurry, corn stalks and microorganisms evenly to obtain a mixture. The slurry accounts for 30% of the mass of the mixture. The mass ratio of corn stalks and microorganisms is 5000:1. The soil remediation agent was obtained by natural fermentation at ℃ for 30 days (the temperature was raised to 65 ℃ during the fermentation process).

Embodiment 2

[0046] The ore soil 7, ore soil 8 and coal ash in Table 2 are mixed according to the mass ratio of 2:1:1, and the obtained mixture is called mine coal ash. Mix 49L of concentrated nitric acid (67% in mass concentration) with 500L of water to obtain a nitric acid solution, gradually add coal ash to the nitric acid solution at room temperature until the pH value reaches 6, stir for 4 hours to fully react, and obtain a slurry. Mix the slurry, corn stalks, pig manure, forest leaves and microorganisms evenly to obtain a mixture. The slurry accounts for 27% of the mass of the mixture, and the mass ratio of the total amount of corn stalks, pig manure and forest leaves to the microorganisms is 10000:1. The mixture was stacked with a height of 1.2m and a width of 2.5m, and then fermented naturally at 32°C (the temperature rose to 70°C during the fermentation process) for 35 days to obtain a soil remediation agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com