A process for preparing Teflon high temperature cloth based on dipping method

A Teflon, high temperature cloth technology, applied in textiles and papermaking, etc., can solve the problems of long time, poor high temperature resistance, complicated impregnation process, etc., achieve simple production process, excellent high temperature resistance, and retain existing characteristics. Effect

Active Publication Date: 2022-05-31

HUANGSHAN MEAO COMPOSITE MATERIALS CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Chinese patent CN 106283684A discloses a preparation method of modified Teflon cloth, which includes the following steps: the non-alkali glass fiber cloth advances at a constant speed under the intelligent control of the equipment, and is fully impregnated with a specific proportion of Conductive carbon powder, polytetrafluoroethylene glue of fumed silica powder used as matte powder and heated, then baked and sintered, and finally cooled, the finally obtained Teflon glass fiber cloth has a certain Strength and elasticity, the matte surface reflects little light, can stick a small amount of fine substances, but not too much; but its high temperature resistance is not good, the maximum heat is 250 ℃, which restricts its application in baking utensils , and the impregnation process of the invention is complex and time-consuming

[0004] Chinese patent CN 110117908A discloses a Teflon high-temperature coated cloth, its manufacturing method and its application, including the following steps: S1: After drying the glass fiber cloth, put it into a deionized aqueous solution for 8-10 minutes and then dry it ; S2: Prepare 50% and 60% polytetrafluoroethylene emulsions; S3: first dipping: soak the dried glass fiber cloth in 60% polytetrafluoroethylene emulsion for 2 minutes, dry ; The second dipping: put the dried glass fiber cloth into 60% polytetrafluoroethylene emulsion for 2 minutes and dry it; the third dipping: put the dried glass fiber cloth into 50% polytetrafluoroethylene emulsion Immerse in polytetrafluoroethylene emulsion for 2 minutes, and dry; S4: Sinter the dried glass fiber cloth and heat press; in order to increase the bonding degree of glass fiber cloth and impregnating liquid in this invention, add Epoxy phenolic resin emulsion, although it increases the adhesion, but epoxy phenolic resin will release toxic gases such as formaldehyde, which restricts its application in baking utensils

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

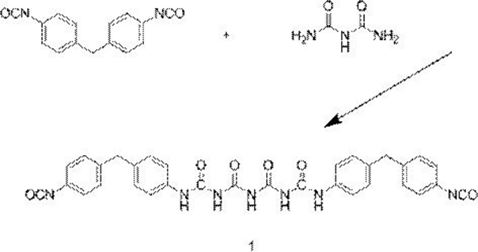

The invention relates to a process for preparing Teflon high-temperature cloth based on an impregnation method, which belongs to the technical field of Teflon cloth preparation and includes the following steps: the first step is to arrange the glass fiber base in the impregnation solution, and ultrasonically Treatment, dipping for 30 minutes, taking out, drying at 100-120°C for 30 minutes, and then drying at 125-150°C for 30 minutes to obtain the crude Teflon fabric; the second step is to dry the crude Teflon fabric at 275-285°C Bake for 4-6 minutes, then sinter at 360-370°C for 8-15 minutes, and cool to obtain Teflon high-temperature cloth based on the impregnation method; by adding modified graphene oxide and high-temperature-resistant acrylate, the impregnation liquid and the base cloth are improved. Compared with the traditional production process, the process is simple, safe and environmentally friendly. While retaining the existing characteristics of Teflon fabric, it also has excellent high temperature resistance.

Description

A process for preparing Teflon high temperature cloth based on dipping method technical field The invention belongs to the technical field of Teflon cloth preparation, particularly, relate to a kind of preparation Teflon high based on dipping method Craftsmanship of Wembley. Background technique [0002] Teflon cloth, scientific name is polytetrafluoroethylene coated glass fiber cloth. Teflon cloth on the market is made of alkali-free or Medium-alkali fiberglass cloth is dipped and coated with PTFE (also known as polytetrafluoroethylene or Teflon) suspension emulsion, and then sintered in a high temperature environment. Chinese patent CN 106283684A discloses a kind of preparation method of modified Teflon cloth, comprises the following steps: no Under the intelligent control and traction of the equipment, the alkali glass fiber cloth moves forward at a constant speed. Proportion of conductive carbon powder, fumed silica powder as matte powder, PTFE glue, heated, and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06N3/04D06N3/00

CPCD06N3/047D06N3/0059D06N3/0063D06N3/0022D06N2205/023D06N2209/10D06N2209/06D06N2209/143D06N2209/16

Inventor 胡少鹏邱惠平

Owner HUANGSHAN MEAO COMPOSITE MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com