Flexible cable for 10MW offshore wind generating set and preparation method of flexible cable

A technology for wind turbines and flexible cables, used in cable/conductor manufacturing, insulated cables, bendable cables, etc., can solve the problem of low tensile strength, aging resistance and tear resistance of flexible cables with tensile strength and torsion resistance. problem, to save the process, improve the tensile performance, increase the effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

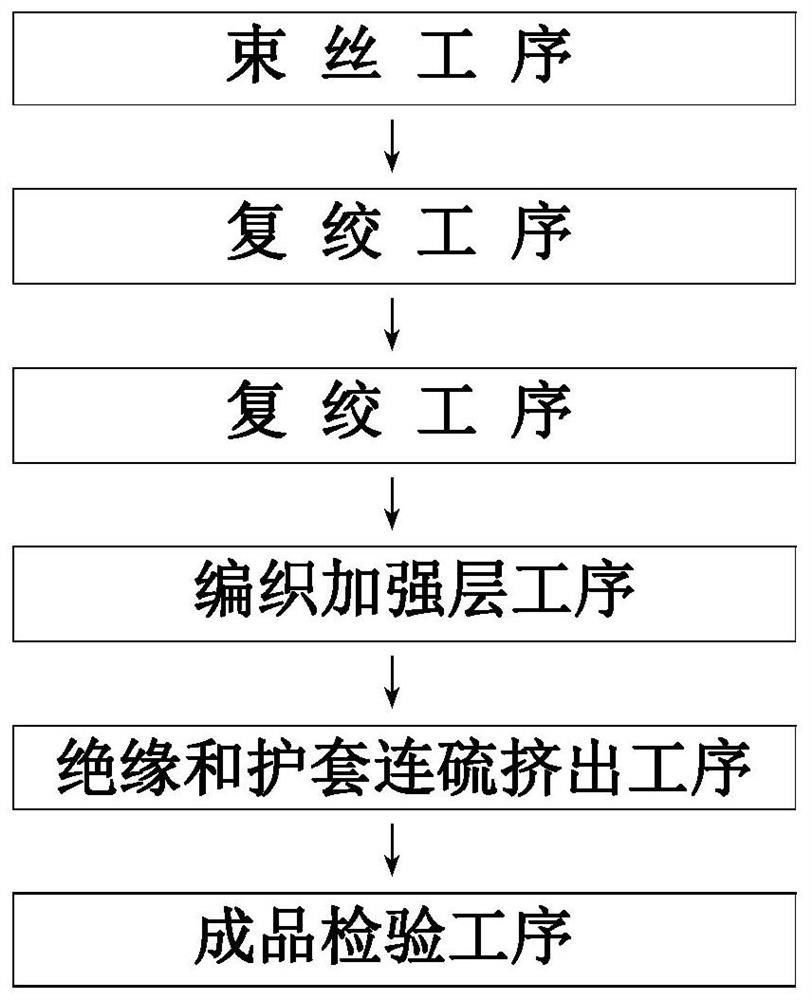

[0053] See attached figure 1 , figure 2 and image 3 .

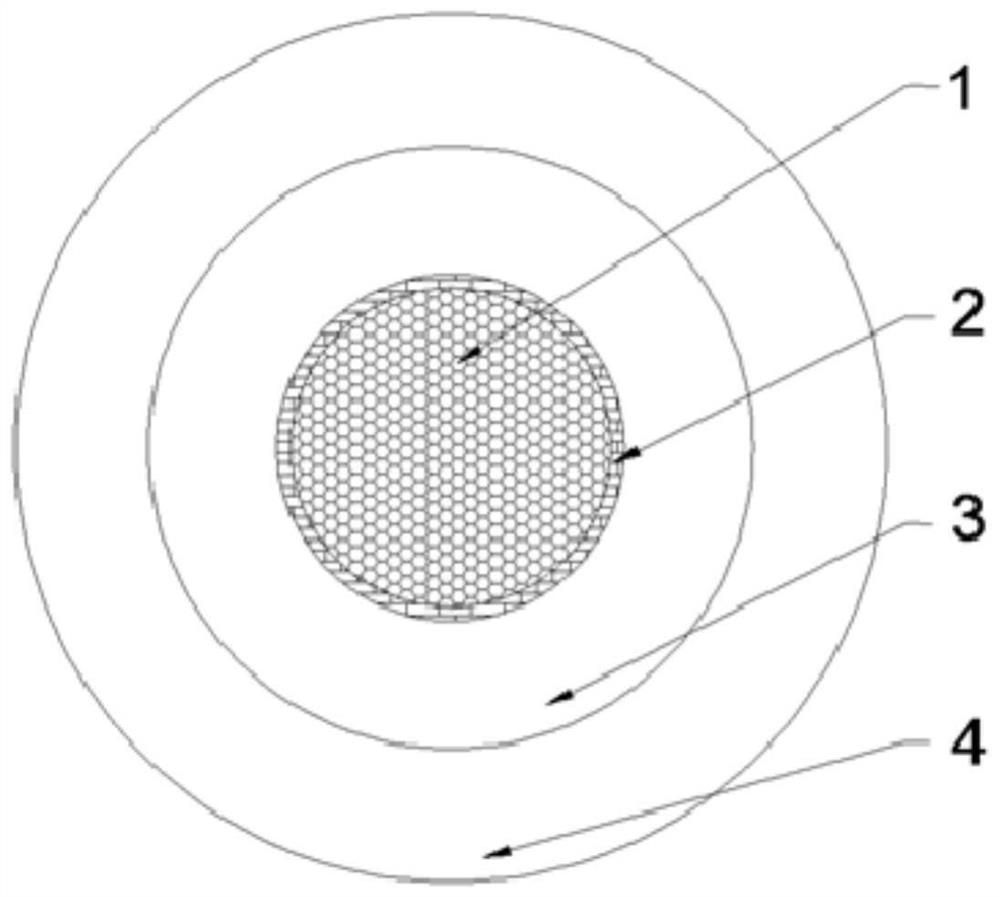

[0054] A flexible cable for a 10MW offshore wind power generating set, which is composed of a conductor, a reinforcement layer, an insulating layer, and a sheath layer. The conductor is composed of a single copper wire and a copper foil wire. It is made of bulletproof silk fiber wire and supported by fiber. The reinforcement layer is woven with Kevlar bulletproof wire. The outside of the conductor is the reinforcement layer, the outside of the reinforcement layer is the insulation layer, and the insulation layer is extruded with a sheath layer.

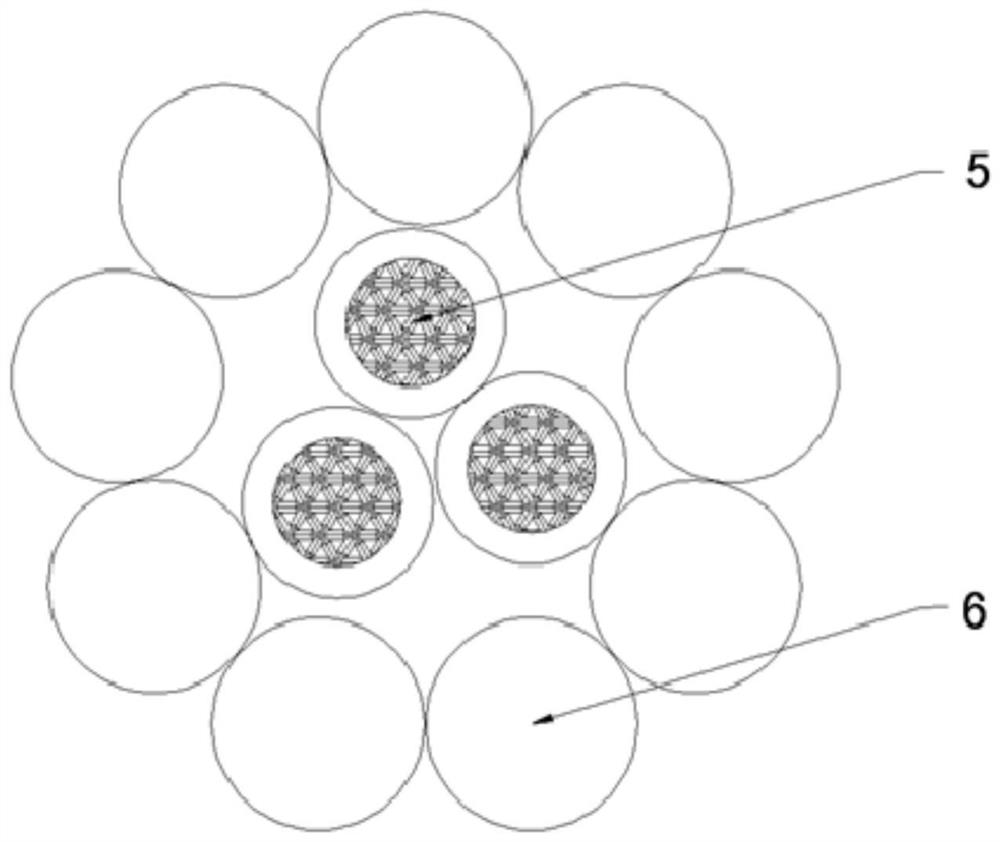

[0055] The conductor is made of 9 copper wires and 3 copper foil wires, the strands are stranded and the pitch ratio is 12 to 20 times. %. The braiding angle of the Kevlar bulletproof wire braided reinforcing layer is 40-50, and the braiding density is 55-60%. The thickness of the insulation layer and the sheath layer are 2mm and 4mm respectively.

Embodiment 2

[0057] See attached figure 1 and figure 2 . A flexible cable for a 10MW offshore wind power generating set, including a conductor 1, composed of copper wire single wire and copper foil wire 5 and 6, wherein the copper foil wire 5 enhances the tensile performance of the conductor; Kevlar bulletproof wire braided reinforcement layer 2, Increase the overall tensile and torsion resistance of the cable. The braiding angle is 40-50°, and the braiding density is 55-60%. The insulating layer 3 and the sheath layer 4 are extruded with new and excellent rubber materials to strengthen the overall resistance of the cable. Tensile and torsion resistance, and the material has excellent high and low temperature resistance, aging resistance, salt spray resistance and flame retardancy. The nominal thickness of the insulating layer 4 and the sheath layer 5 are 3.0mm and 4.0mm respectively, the thinnest point The thicknesses are 2.7mm and 3.3mm respectively.

[0058] The concrete implementat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com