Film bulk acoustic resonator and manufacturing method thereof

A thin-film bulk acoustic wave and manufacturing method technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of radio frequency systems that cannot meet high performance, the quality factor cannot be further improved, and the quality factor is poor, so as to strengthen the firmness and avoid damage , the effect of preventing sound wave leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

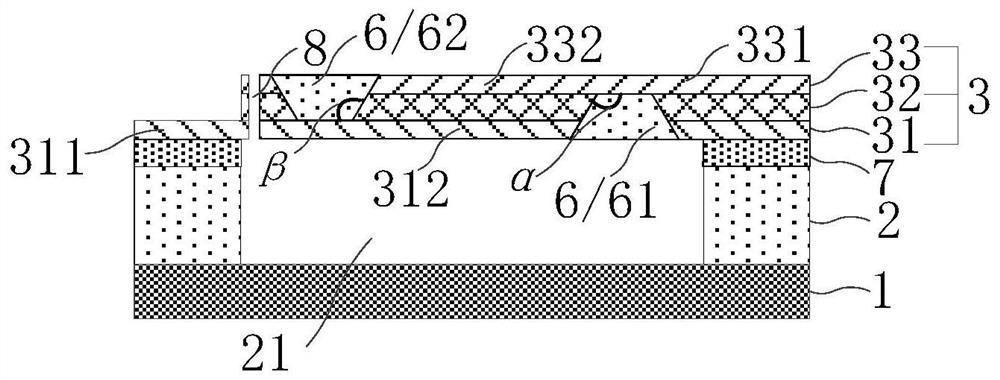

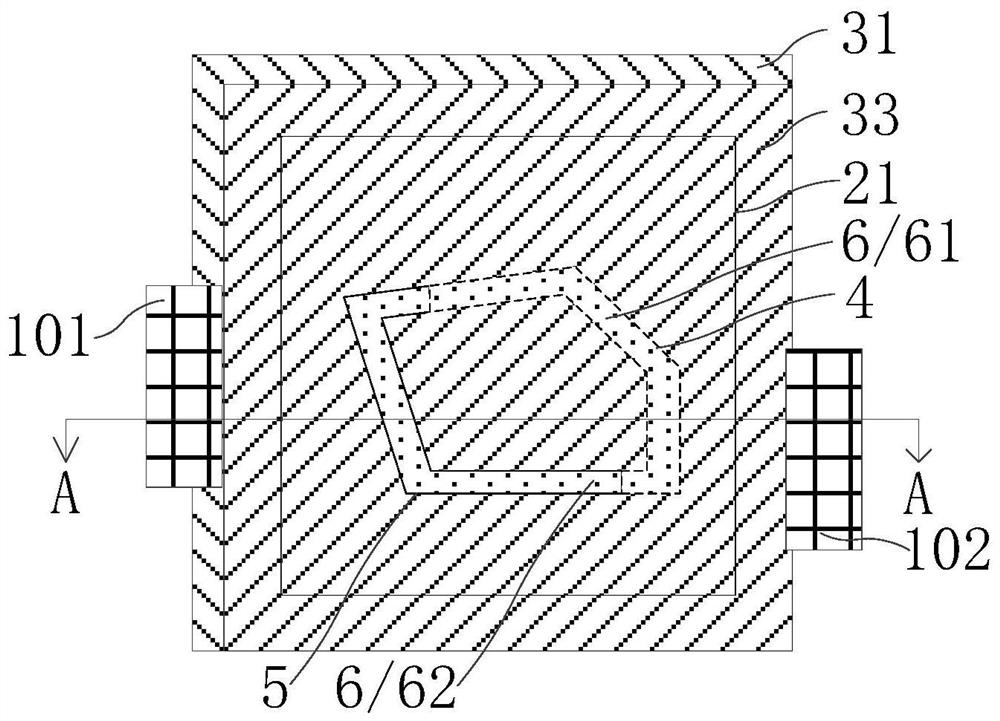

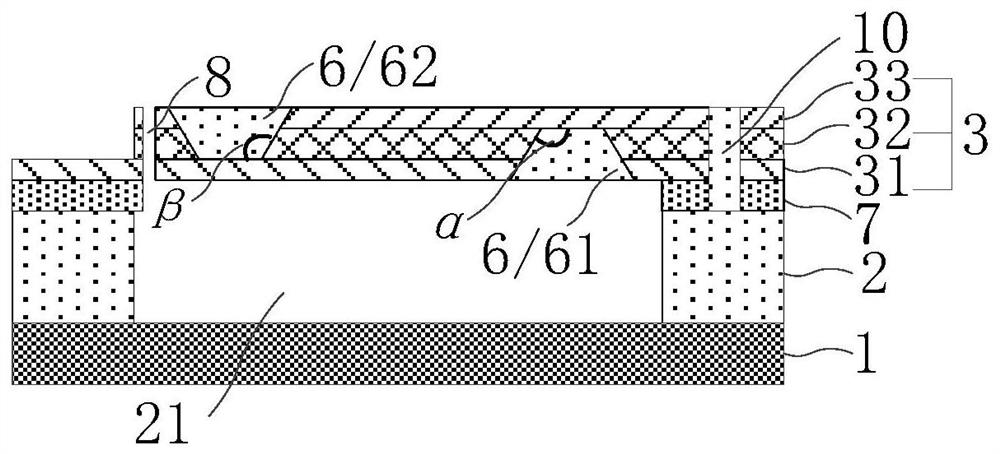

[0040] The cavity-type thin-film bulk acoustic resonators produced at present have problems such as sound wave loss and insufficient structural strength, so that the quality factor (Q) cannot be further improved, and the yield is low, so they cannot meet the needs of high-performance radio frequency systems.

[0041] In order to solve the above problems, the present invention provides a thin film bulk acoustic resonator. By filling the trench with a dielectric layer, it forms a support with the electrodes in the region where the trench is located, thereby enhancing the firmness of the device structure and avoiding the resonator structure. damage, protect the device structure, and improve device performance.

[0042] The thin film bulk acoustic resonator and its manufacturing method of the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. According to the following description and accompanying drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com