A sheet metal laser cutting machine with a pressure transmission nozzle

A laser cutting machine and pressure technology, applied in the field of transmission, can solve the problems of pollution of other accessories and affect the cutting quality of sheet metal parts, and achieve the effect of avoiding pollution, avoiding economic losses and accurate distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

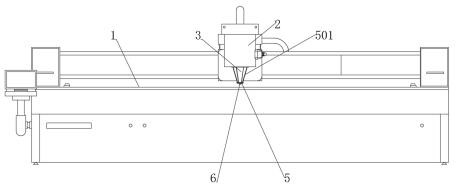

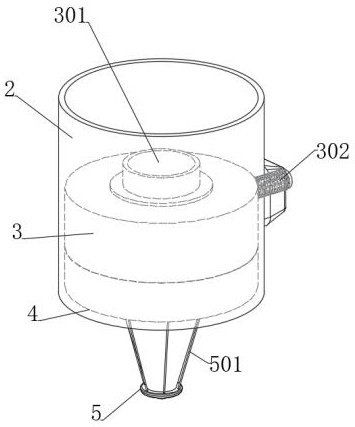

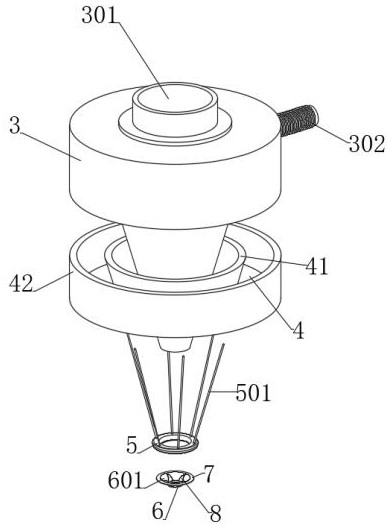

[0043] see Figure 1-10 , a sheet metal laser cutting machine with a pressure transmission nozzle, including a laser tube 2 installed on the laser cutting machine body 1, a laser nozzle 3 is slidably connected to the laser tube 2, see Figure 1-3 with Figure 8 , Figure 10 The upper end of the laser nozzle 3 is fixedly connected with a laser beam tube 301 connected to it, and the right end of the laser nozzle 3 is fixedly connected with a flexible air inlet pipe 302 connected with it, and the flexible air tube 302 is located on the lower side of the laser beam tube 301. The lower inner wall of the laser tube 2 is fixedly connected with a pressure fine-tuning collar 4 matched with the laser nozzle 3, the lower end of the laser nozzle 3 extends to the outside of the laser tube 2, and is fixedly connected with a plurality of triangular drainage petals 601, and the lower ends of the plurality of triangular drainage petals 601 The nozzle extension ring 6 is fixedly connected, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com