High polymer modified rubber leaking stoppage material for oil-based drilling fluid leaking stoppage and preparation method thereof

A technology of oil-based drilling fluid and polymer modification, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of poor plugging effect and insufficient retention of ordinary rubber, so as to improve the plugging effect. performance, solving residency difficulties, and improving residency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

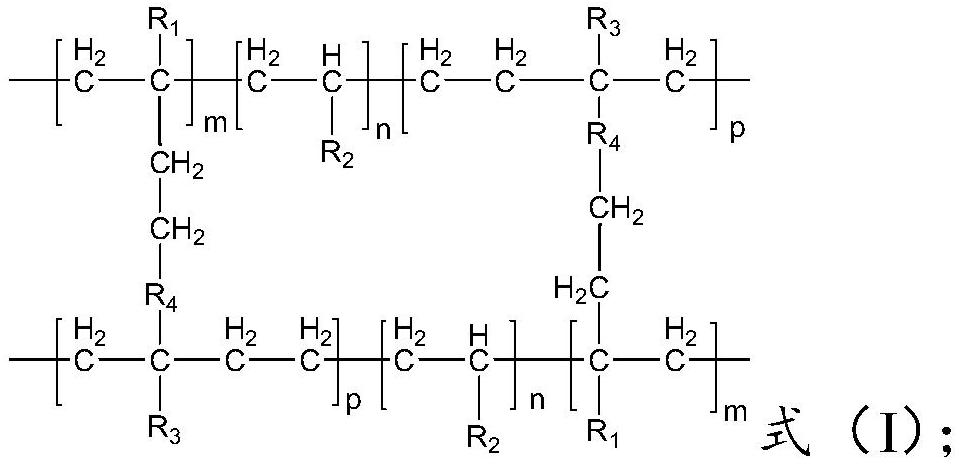

[0037] The invention provides a method for preparing a polymer-modified rubber plugging material for oil-based drilling fluid plugging, comprising:

[0038] High polymer containing active groups, rubber, solvent, oil-soluble cross-linking agent, oil-soluble initiator are mixed, heated for reaction, and shear granulated to obtain a weakly cross-linked polymer for oil-based drilling fluid plugging;

[0039] The high polymer containing active groups is one or more of polybutadiene, polyisoprene, polybutadiene-styrene, polyacrylonitrile-butadiene-styrene and the like.

[0040] The preparation method of the high polymer modified rubber plugging material for oil-based drilling fluid plugging provided by the invention mixes the high polymer containing active groups, rubber, solvent, oil-soluble cross-linking agent and oil-soluble initiator.

[0041] First, the high polymer containing active groups is dissolved in a solvent or heated and melted, and stirred.

[0042] The polymer cont...

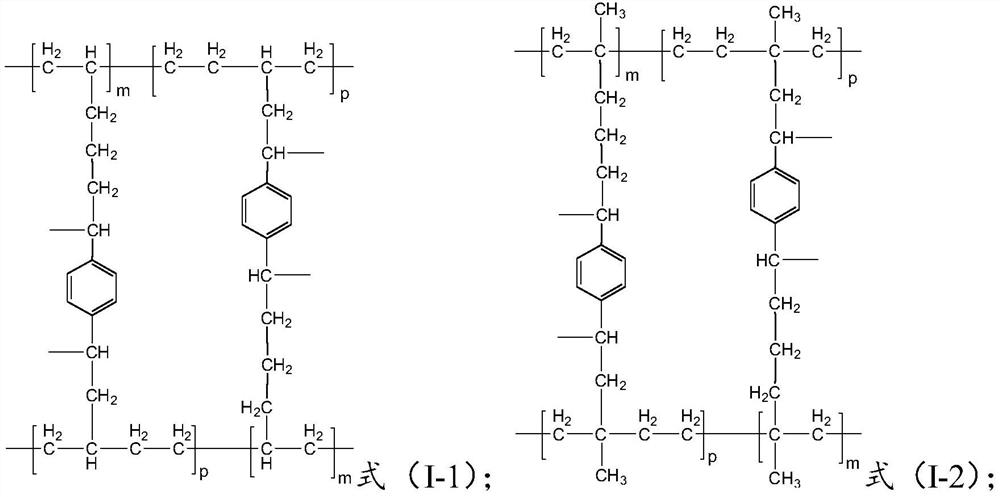

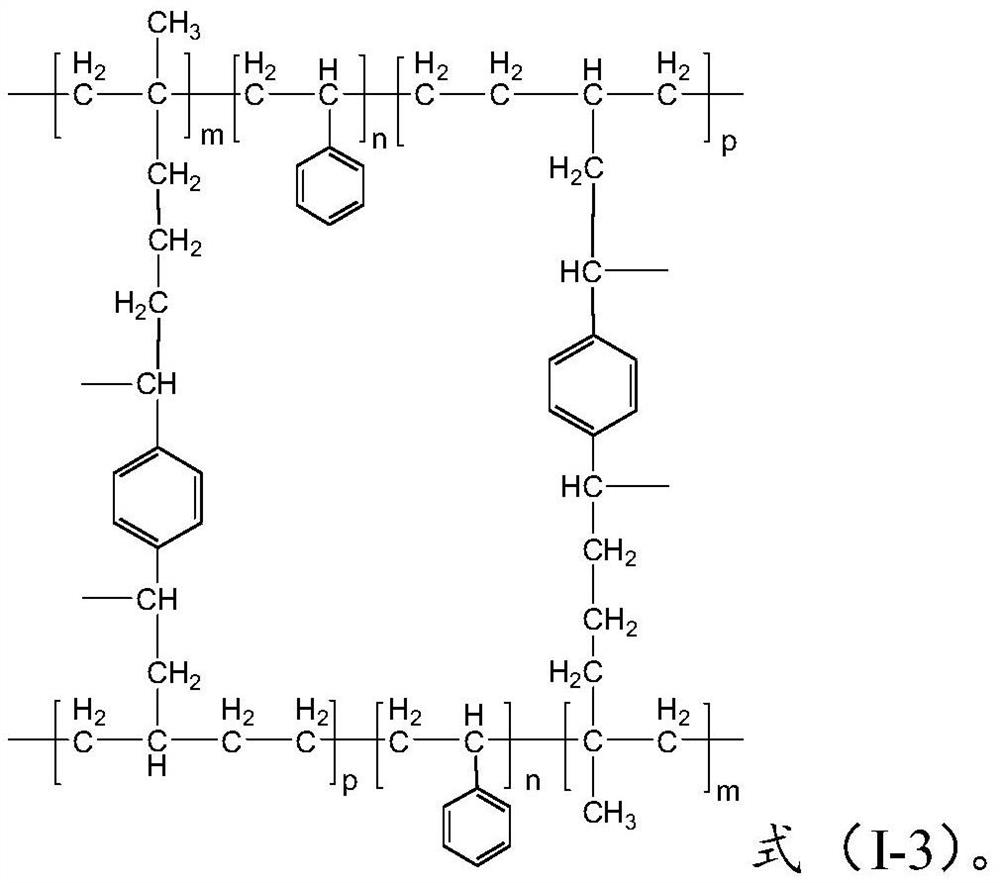

Embodiment 1

[0077] Dissolve 20g of polybutadiene in ethyl acetate, add 2g of waste tire rubber powder, 0.8g of cross-linking agent divinylbenzene, 0.8g of initiator AIBN after fully dissolving, stir well, heat to 80°C, polymerize for 6h, Granulation to obtain a polymer plugging material with a core-shell structure, in which the structural formula of the weakly crosslinked shell (left) and the entire core-shell structure (right) are:

[0078]

[0079] Wherein, the molecular weight is 250,000-330,000, m, p is the degree of polymerization, and the range is m:p=(450-560):(4100-5100).

Embodiment 2

[0081] Dissolve 20g of polyisoprene in ethyl acetate, add 2g of natural rubber powder after fully dissolving, add 0.8g of crosslinking agent divinylbenzene, 0.8g of initiator BPO, stir well, heat to 80°C, and polymerize for 6h , granulated to obtain a polymer plugging material with a core-shell structure, in which the structural formula of the weakly cross-linked shell (left) and the entire core-shell structural formula (right) are:

[0082]

[0083] Wherein, the molecular weight is 280,000-350,000, m, p is the degree of polymerization, and the range is m:p=(400-750):(3400-4500).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com