Hollow-structure material as well as preparation method and application thereof

A hollow structure and hollow nano technology, which is applied in the preparation of microspheres, structural parts, microcapsule preparations, etc., can solve the problems of difficulty in large-scale promotion and the limitation of material synthesis efficiency in the synthesis process, and achieve easy operation and easy control of conditions , Improve the effect of reaction kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Preparation of metal organic framework ZIF-8:

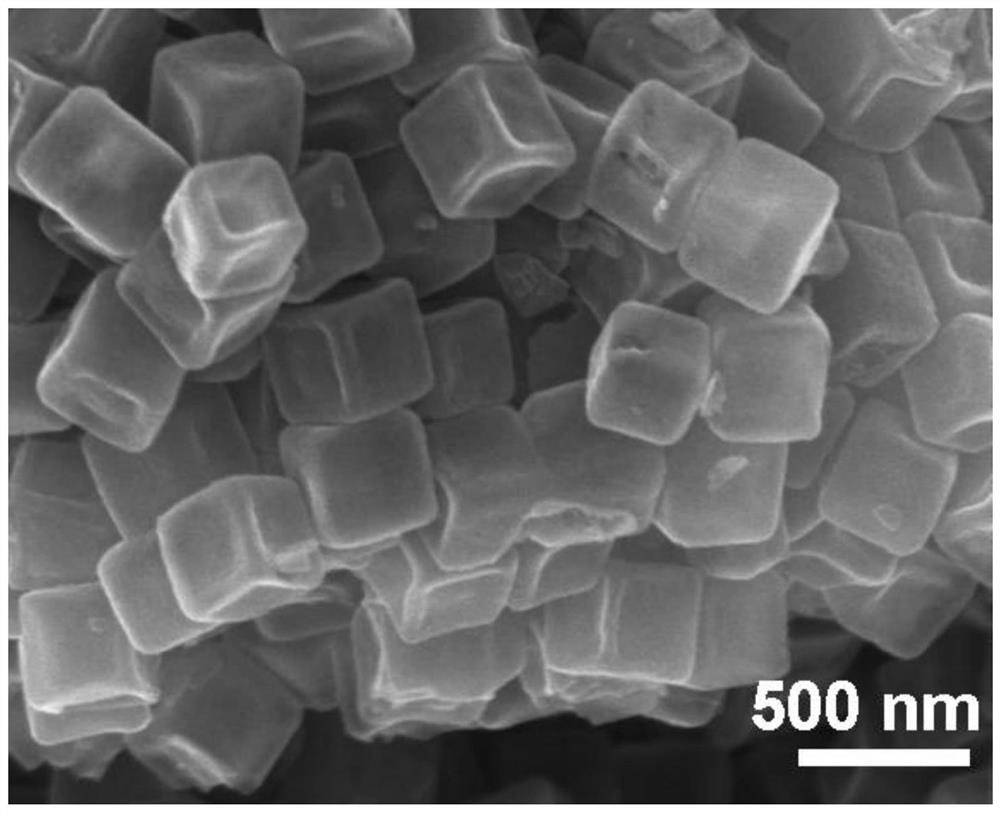

[0031] Dissolve 6g of zinc acetate in 100ml of deionized water, dissolve 18.22mg of CTAB and 22.33g of dimethylimidazole in 100ml of deionized water, then mix and stir the two solutions for 5min, leave to age for 3h to obtain a white suspension, and centrifuge to wash and dry Finally, a white metal-organic framework ZIF-8 solid powder was obtained.

[0032] (2) Preparation of multi-chamber metal-organic framework ZIF-8:

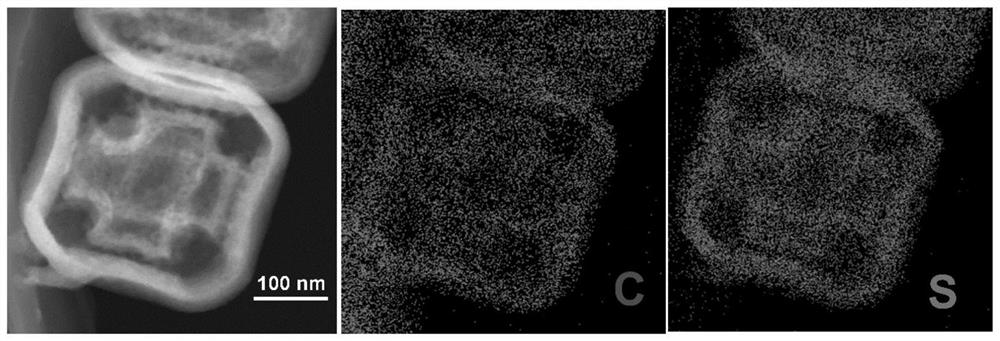

[0033] Take 0.5g metal organic framework ZIF-8 powder and disperse it in 150ml deionized water, take 1.25g tannic acid and dissolve it in 100ml deionized water, mix and stir the two solutions for 5min, so that tannic acid can etch ZIF-8, The multi-chamber metal-organic framework ZIF-8 solid powder was obtained after centrifugal washing and drying.

[0034] (3) Preparation of multi-chamber hollow carbon materials:

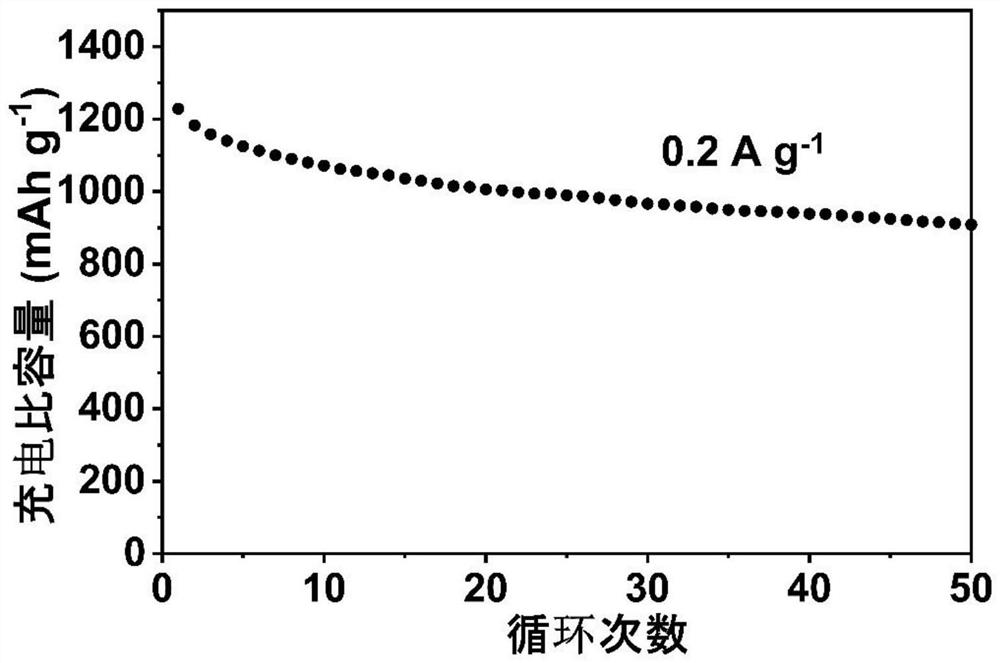

[0035] The obtained multi-chamber metal-organic framework ZIF-8 solid powder was hea...

Embodiment 2

[0043] (1) Preparation of metal organic framework ZIF-8:

[0044]Dissolve 6g of zinc acetate in 100ml of deionized water, dissolve 18.22mg of CTAB and 22.33g of dimethylimidazole in 100ml of deionized water, then mix and stir the two solutions for 5min, leave to age for 2h to obtain a white suspension, and centrifuge to wash and dry Finally, a white metal-organic framework ZIF-8 solid powder was obtained.

[0045] (2) Preparation of simple hollow metal-organic framework ZIF-8:

[0046] Take 0.5g metal organic framework ZIF-8 powder and disperse it in 150ml deionized water, take 1.25g tannic acid and dissolve it in 100ml deionized water, mix and stir the two solutions for 60min, so that tannic acid can etch ZIF-8, The simple hollow metal-organic framework ZIF-8 solid powder was obtained after centrifugal washing and drying.

[0047] (3) Preparation of simple hollow carbon materials:

[0048] The obtained multi-chamber metal-organic framework ZIF-8 was heated to 900 °C for 3 ...

Embodiment 3

[0051] (1) Preparation of metal organic framework ZIF-8:

[0052] Dissolve 6g of zinc acetate in 100ml of deionized water, dissolve 18.22mg of CTAB and 22.33g of dimethylimidazole in 100ml of deionized water, then mix and stir the two solutions for 5min, leave to age for 2h to obtain a white suspension, and centrifuge to wash and dry Finally, a white metal-organic framework ZIF-8 solid powder was obtained.

[0053] (2) Preparation of ZIF8@ZIF67:

[0054] Take 0.6g ZIF-8 and 0.6g Co(NO 3 ) 2 ·6H 2 O was dispersed in 200 ml of methanol, 0.6 g of dimethylimidazole was dissolved in 100 ml of methanol, the two solutions were mixed and stirred for 2 h, and the ZIF8@ZIF67 solid powder was obtained after centrifugal washing and drying.

[0055] (3) Preparation of egg yolk-eggshell structure:

[0056] Take 0.5g of ZIF8@ZIF67 solid powder and disperse it in 150ml of deionized water, take 1.25g of tannic acid and dissolve it in 100ml of deionized water, mix and stir the two solution...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap