Smashing and stirring system and efficient chicken essence production line using same

A technology of a stirring system and production line, which is applied to mixers, mixer accessories, containers and other directions with a rotating stirring device, can solve the problems of low work efficiency and long time consumption, and achieves reduced labor intensity, shortened time consumption, and improved mixing. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

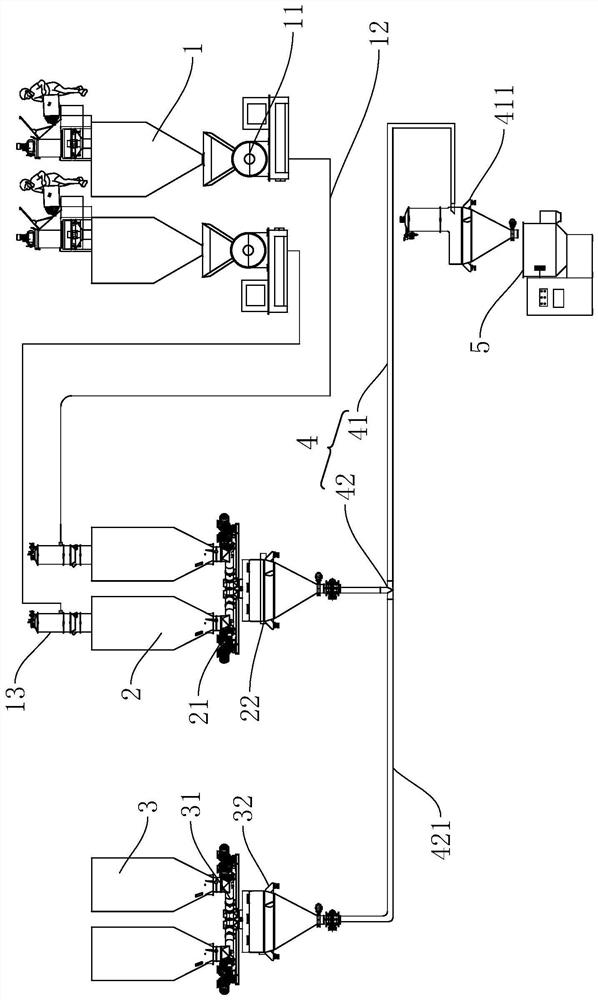

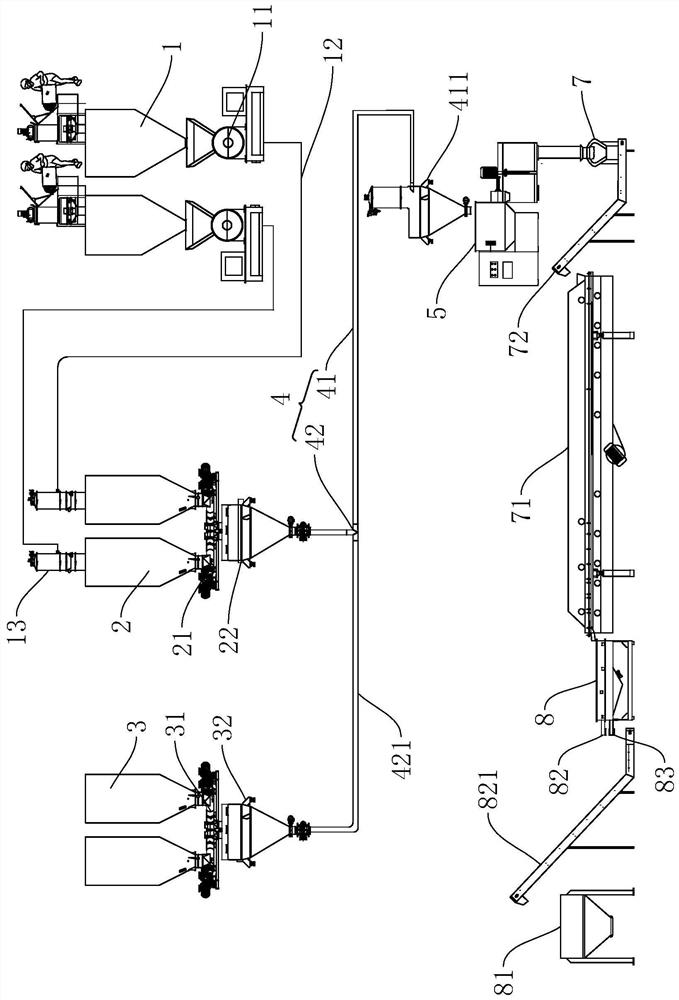

[0044] In the first aspect, the present application discloses a pulverized stirring system. Refer figure 1 A pulverized stirring system, including a pellet feed bin 1, a pellet feed bin 1, which is provided with a plurality of bulk material and a particulate feedstock. The discharge port of the pellet feed warehouse 1 is connected to a pulverizer 11, and the pulverizer 11 is connected to the first vacuum upper material 13 by the first pneumatic conveying pipe 12, and the first vacuum upper material 13 is connected to the first. Raw material storage position 2. The raw material after pulverizing the pulverizer 11 is converted from a block or a particulate shape to a particulate or powdered shape, and stored in the first raw material storage bin 2.

[0045] Refer figure 1 The system also includes a second raw material storage bin 3, and a second raw material storage bin 3 is provided with a plurality of storage for a plurality of powder raw materials. Hereinafter, the first raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com