Method for preparing copper sulfate solution for electrolytic copper foil by dissolving waste copper wire

A technology of electrolytic copper foil and copper sulfate, which is applied in the direction of electrolysis, electroforming, and improvement of process efficiency, can solve problems such as uneven contact of copper materials, low equipment efficiency, and poor continuity of process flow, etc., to achieve improved reaction speed and The effect of heat release, saving steam heating, and improving the efficiency of copper dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

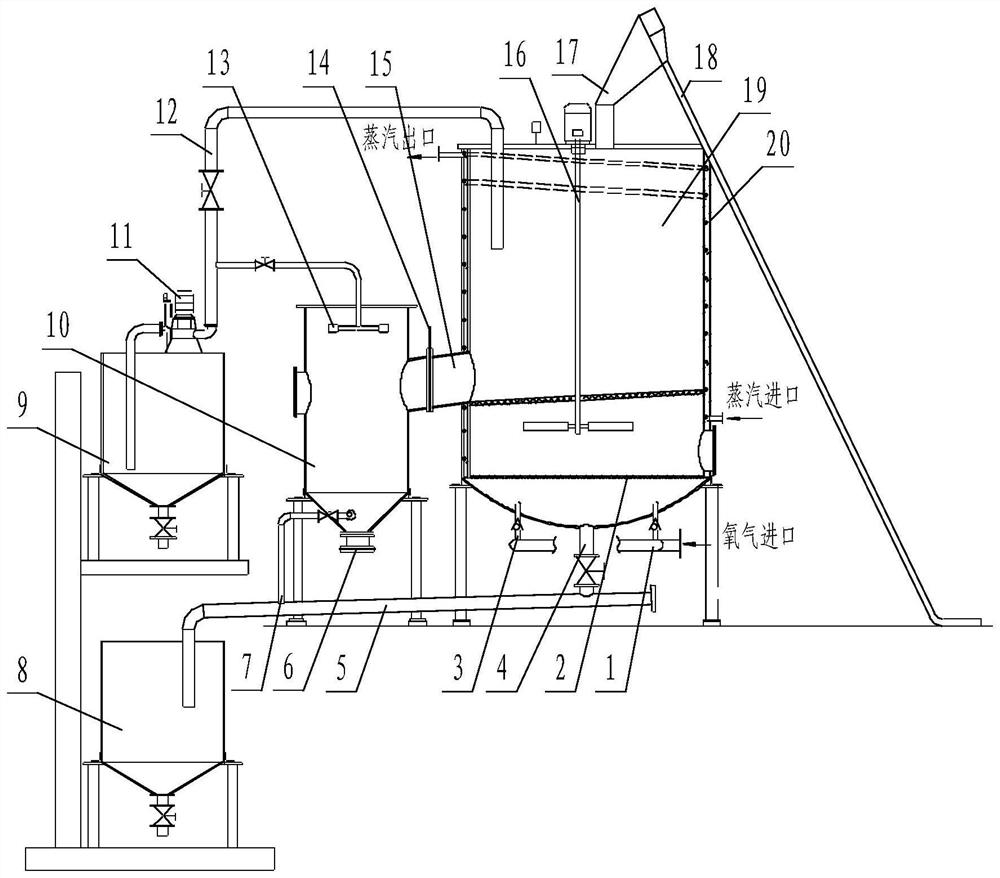

[0012] The present invention provides such figure 1 A kind of copper sulfate liquid method for preparing electrolytic copper foil by dissolving waste copper wire shown as shown comprises the following steps: A, feeding: after rolling the copper sheet with a thickness less than 0.50mm with a rolling mill, the material is conveyed by a belt, and the feeding device 17 adds In the dissolving tank 19, open the acid and alkali resistant chemical pump 11 to extract the sulfuric acid from the sulfuric acid storage tank 9 to the dissolving tank 19 through the liquid inlet pipe 12, control the concentration of sulfuric acid to be 5% to 50%, and fully impregnate the waste copper wire; B , Oxygen: from the oxygen inlet into the air with a pressure of 0.2-0.6Mpa, pure oxygen or oxygen-enriched oxygen with an oxygen content greater than 30%, the gas enters the dissolution tank 19 through the intake ring pipe 1 and the intake branch pipe 3, and then passes through the The dispersed nano-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com