System for discharging waste gas and waste water in mine by using oxygen-enriched tail gas of PSA (Pressure Swing Adsorption) nitrogen making machine

A technology of internal exhaust gas and nitrogen generator, applied in inorganic chemistry, gas treatment, nitrogen compounds, etc., can solve the problems of being unable to be used and discharged into the atmosphere, and achieve the effects of reducing the risk of suffocation, avoiding waste, and increasing the circulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

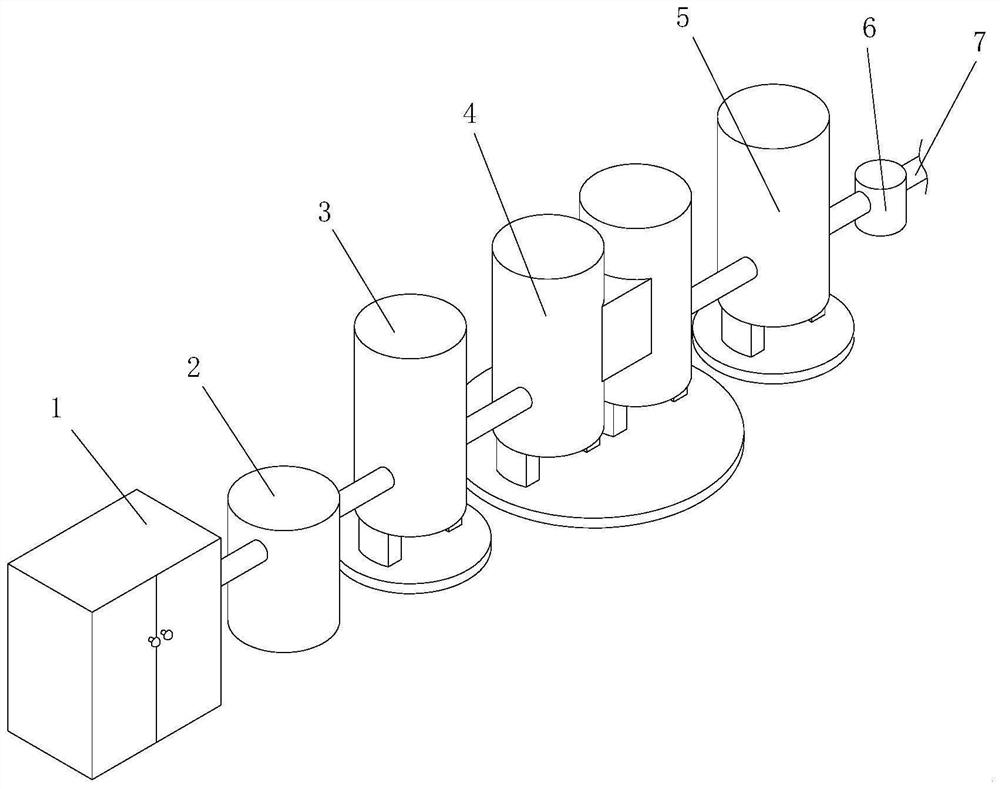

[0032] see Figure 1-5, the present invention provides a technical solution: a system for removing waste gas and waste water in a mine by utilizing the oxygen-enriched tail gas of a PSA nitrogen generator, comprising an air compressor 1 connected to an air purification device 2 through a pipeline, and the air purification device 2 passes through The pipeline is connected with an air storage tank 3, the air storage tank 3 is connected with an oxygen and nitrogen separation device 4 through a pipeline, the oxygen and nitrogen separation device 4 is connected with a nitrogen buffer tank 5 through a pipeline, and the nitrogen buffer tank 5 is connected with a flowmeter 6 through a pipeline, and the flowmeter 6 is fixedly connected with a gas pipeline 7, and the oxygen-enriched tail gas discharged from the PSA nitrogen generator is transported into the mine through the gas pipeline 7 to increase the air circulation rate in the mine, and at the same time, the oxygen content in the ox...

Embodiment 2

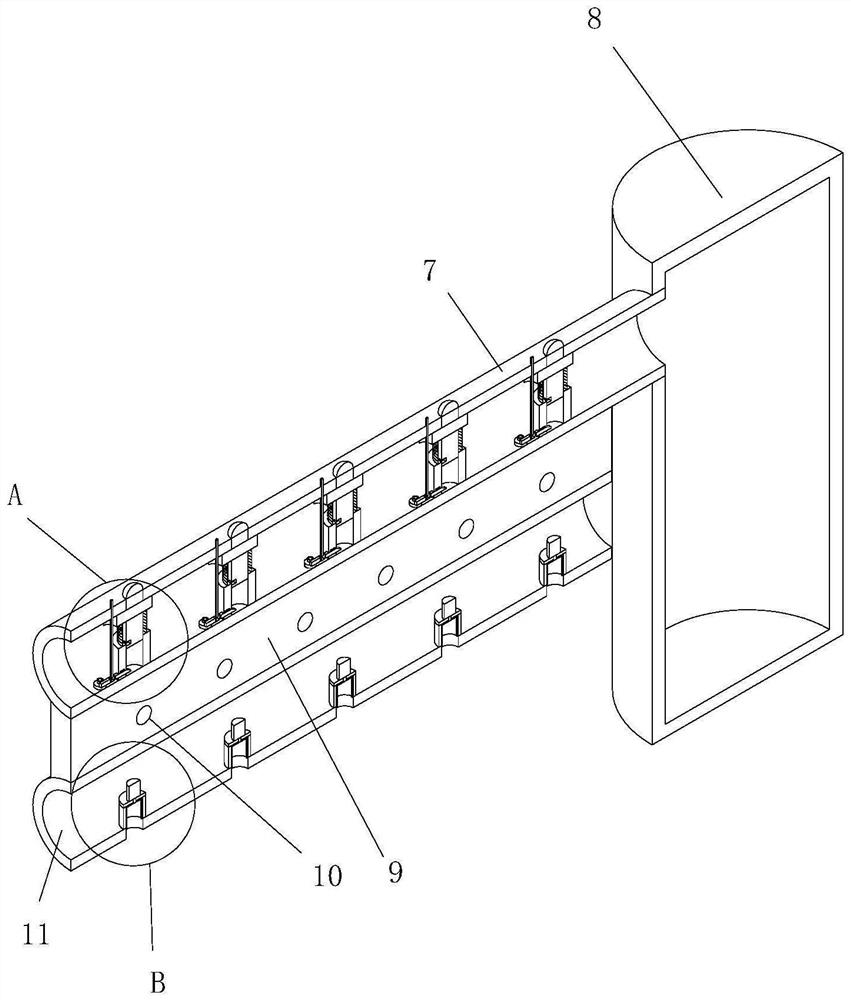

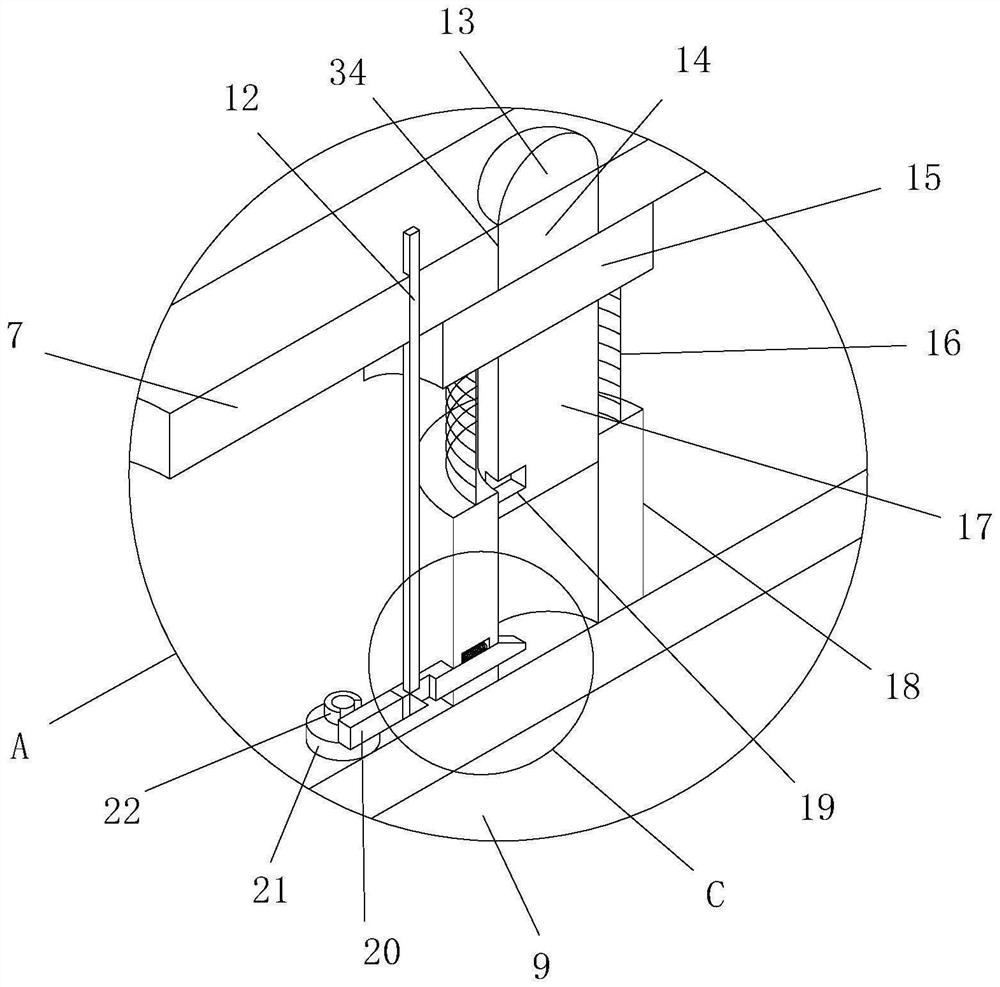

[0039] On the basis of Example 1, please refer to Figure 1-5 , the connection plate 9 is fixedly installed on the air delivery pipe 7, the connection plate 9 is provided with an installation groove 10, the lower side of the connection plate 9 is fixedly installed with an air outlet pipe 11, and the upper side of the air outlet pipe 11 is provided with an air inlet groove 27, and the air outlet pipe 11. A group of filter tubes 24 are fixedly installed on the inner side wall, and each filter tube 24 communicates with each air inlet groove 27 respectively. A filter plate 28 is fixedly installed on the upper end of each filter tube 24, and a filter plate 28 is fixedly installed on the upper side of each filter plate 28. Rotary drive 23, the output shaft of rotary drive 23 moves through filter plate 28, and the output shaft of rotary drive 23 is fixedly connected with rotary bar 26, and rotary bar 26 is fitted with filter plate 28 lower side, and two rotary bar 26 lower sides are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com